Method for detecting f.CaO influencing the utilization of stabilization of steel slag

A technology of stability and determination method, which is applied in the direction of chemical analysis by titration method, preparation of test samples, analysis by chemical indicators, etc., and can solve problems such as different degrees of stability influence

Active Publication Date: 2010-02-24

MCC BAOSTEEL TECH SERVICE

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Conventional detection methods are difficult to distinguish, and the degree of impact on stability is also different

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0040] 1. Test equipment and chemicals:

[0041] Screens: 0.045mm, 0.061mm, 0.125mm, 3mm, 5mm, 10mm sieves.

[0042] Equipment: balance, oven, vibrating screen machine, sample making machine, shaking machine, centrifuge.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

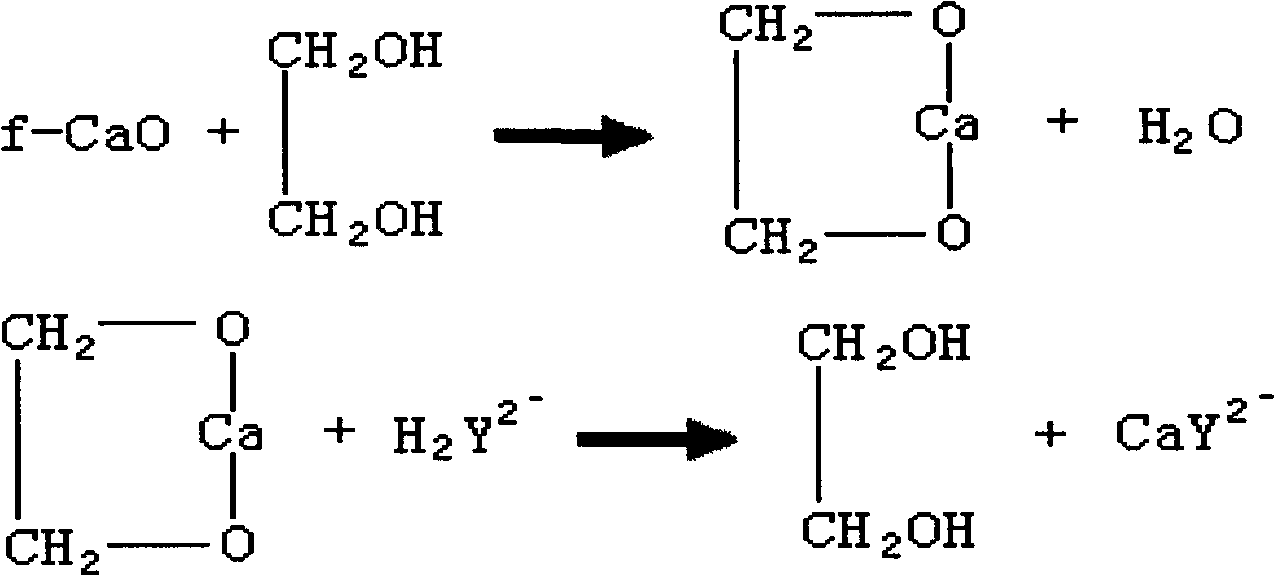

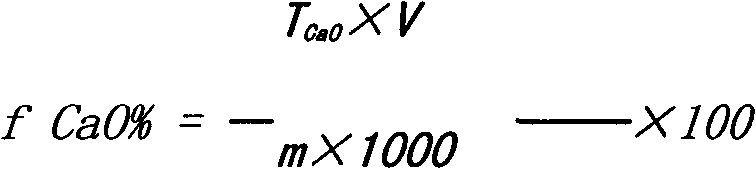

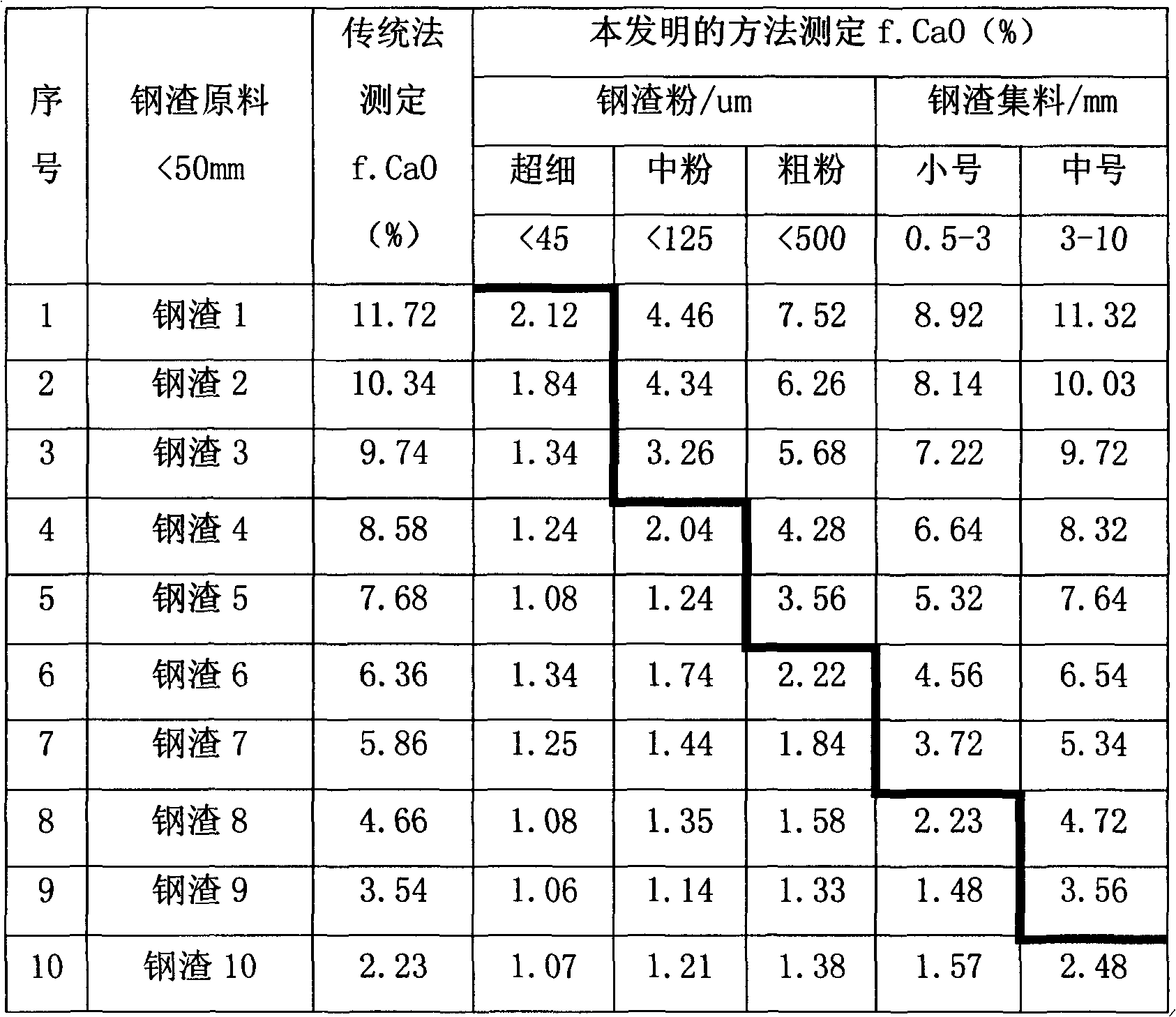

The invention discloses a method for detecting f.CaO influencing the utilization of stabilization of steel slag, comprising the following steps: a. adding water in a steel slag sample at normal temperature, stirring and soaking to dissolve Ca(OH)2 in the slag sample; b. measuring the pH value of a free water solution which is dipped and deposited in defined time; c. continuously stirring a slag sample solid obtained by solid-liquid separation, dipping and depositing in defined time; d. repeating the steps of b and c till the pH value of the measured solution is neutral; and e. measuring the f.CaO of the slag sample solid obtained by separation by a glycol method. The method objectively reflects the degree of the content of the harmful f.CaO in the utilization of the steel slag, thereby providing a test and measuring guarantee for the utilization of the stabilization of the steel slag.

Description

technical field [0001] The invention relates to the field of steel slag detection, in particular to a f.CaO detection method that affects the stability and utilization of steel slag. Background technique [0002] Comprehensive utilization of resources is a long-term strategic policy for national economic and social development. It is an inevitable choice for the metallurgical industry to develop a circular economy with cleaner production as the center and achieve sustainable development. However, for a long time, due to the significant impact of harmful free calcium oxide (hereinafter referred to as "f.CaO") on stable utilization, steel slag resources have always been a difficulty in resource development and utilization, and comprehensive utilization was once seriously hindered. Therefore, improving the detection level of harmful f.CaO content is an inevitable requirement for the development and utilization of steel slag resources in the development of the iron and steel in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N31/16G01N31/22G01N1/28

Inventor 王幼琴杨刚张健金强

Owner MCC BAOSTEEL TECH SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com