High-integration intelligent power module

A power module and intelligent technology, applied in output power conversion devices, electrical components, etc., can solve the problems of low integration, imperfect three-phase N-terminal current detection interface functions, etc., and achieve simple system construction and integration. High and reduce the effect of malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

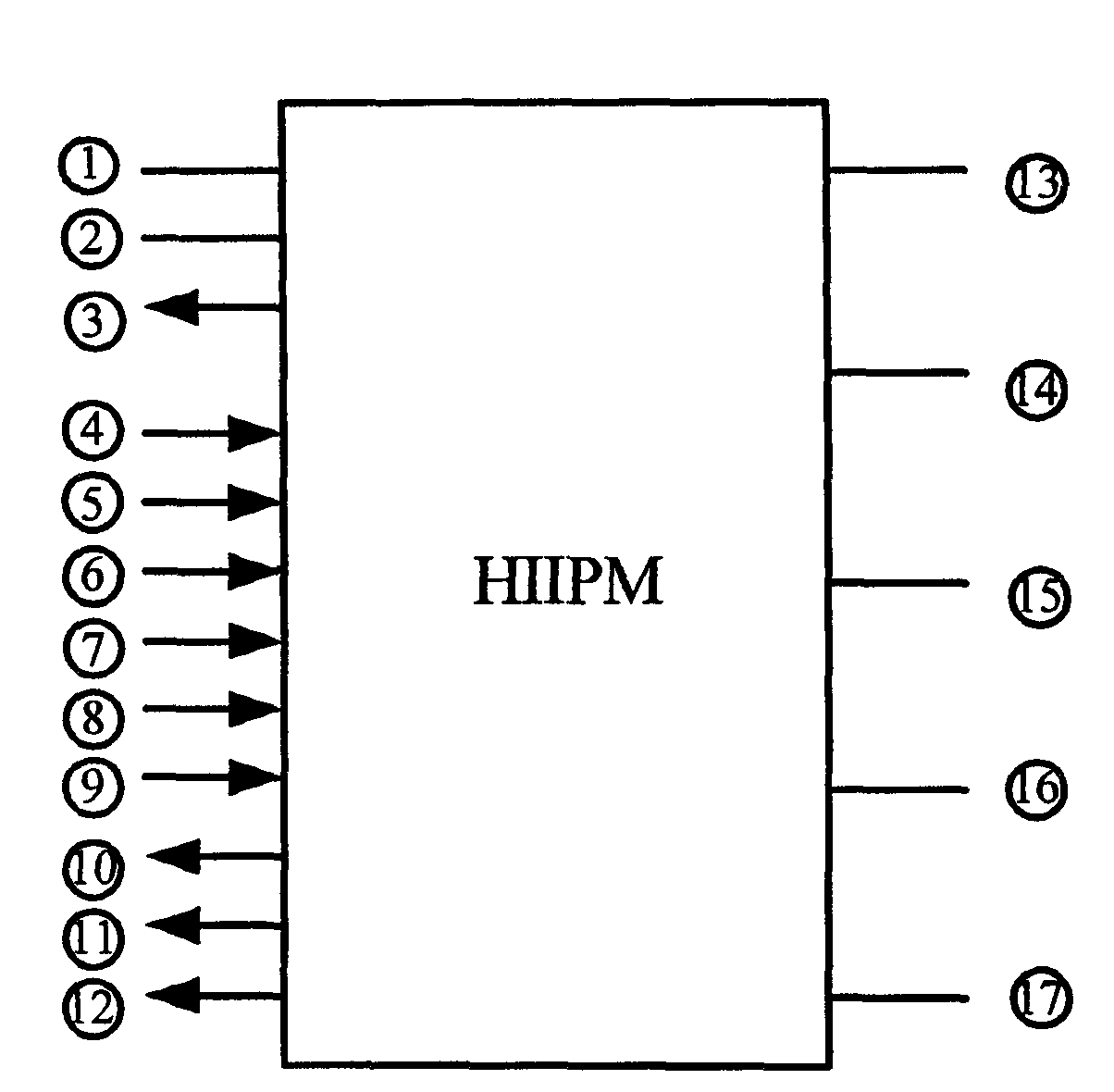

[0016] Such as figure 1 Shown is the external pin schematic diagram of the present invention. The present invention utilizes new materials to fill the assembly process, and reduces conventionally defined external pins without increasing the volume of the IPM for packaging. The present invention only needs 17 pins, including: DC power supply pins (pin 1 and pin 2), error output signal (pin 3), six-way PWM control signal (pin 4-pin 9), three-phase N-terminal current detection signal (pin 10-pin 12), power side DC (pin pin 13 and pin 17), three-phase output pins (pin 14-pin 16). By greatly reducing the external pins of conventional IPMs, the present invention makes the IPMs more integrated and more reliable, thus making its application and system construction easier.

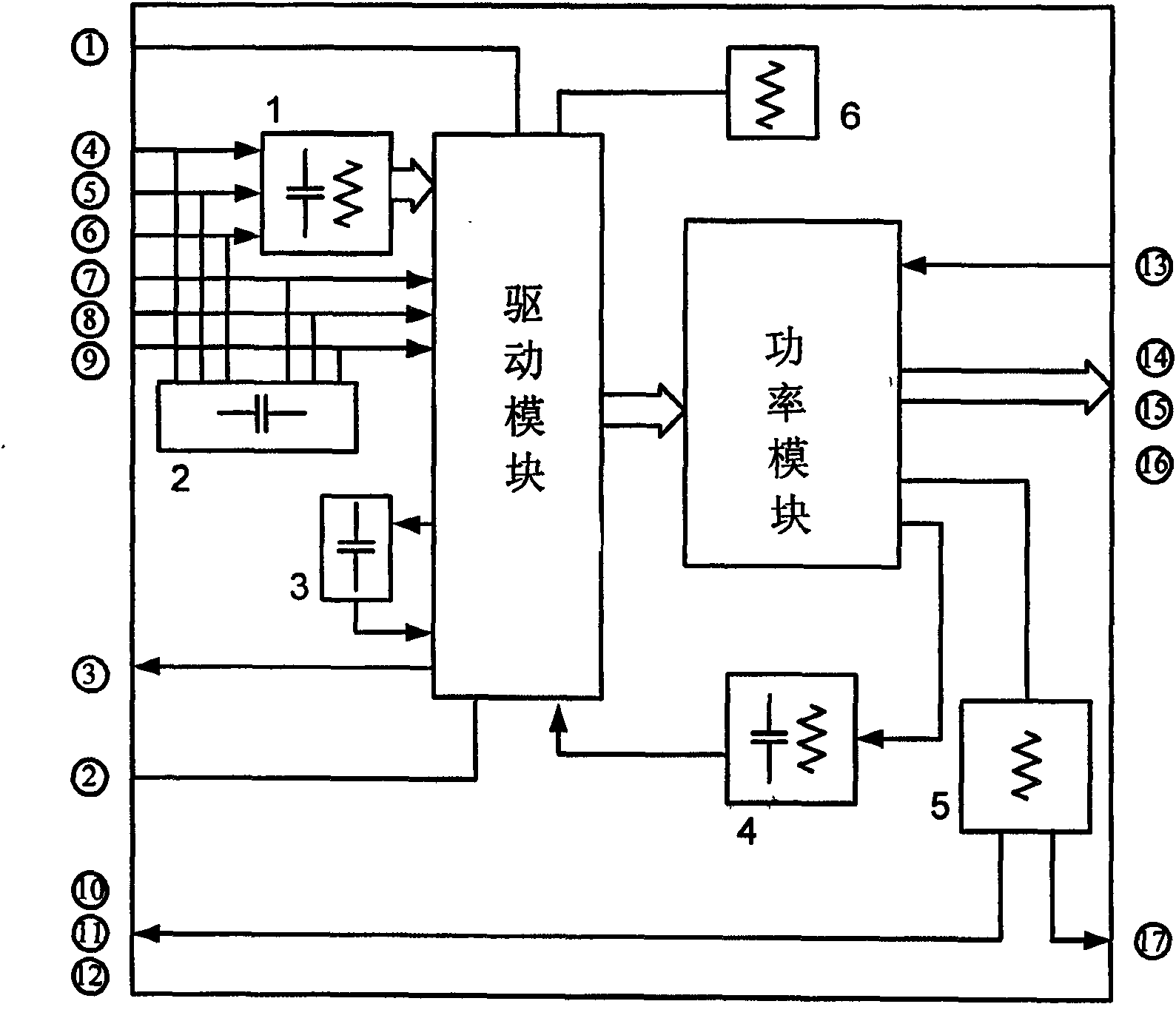

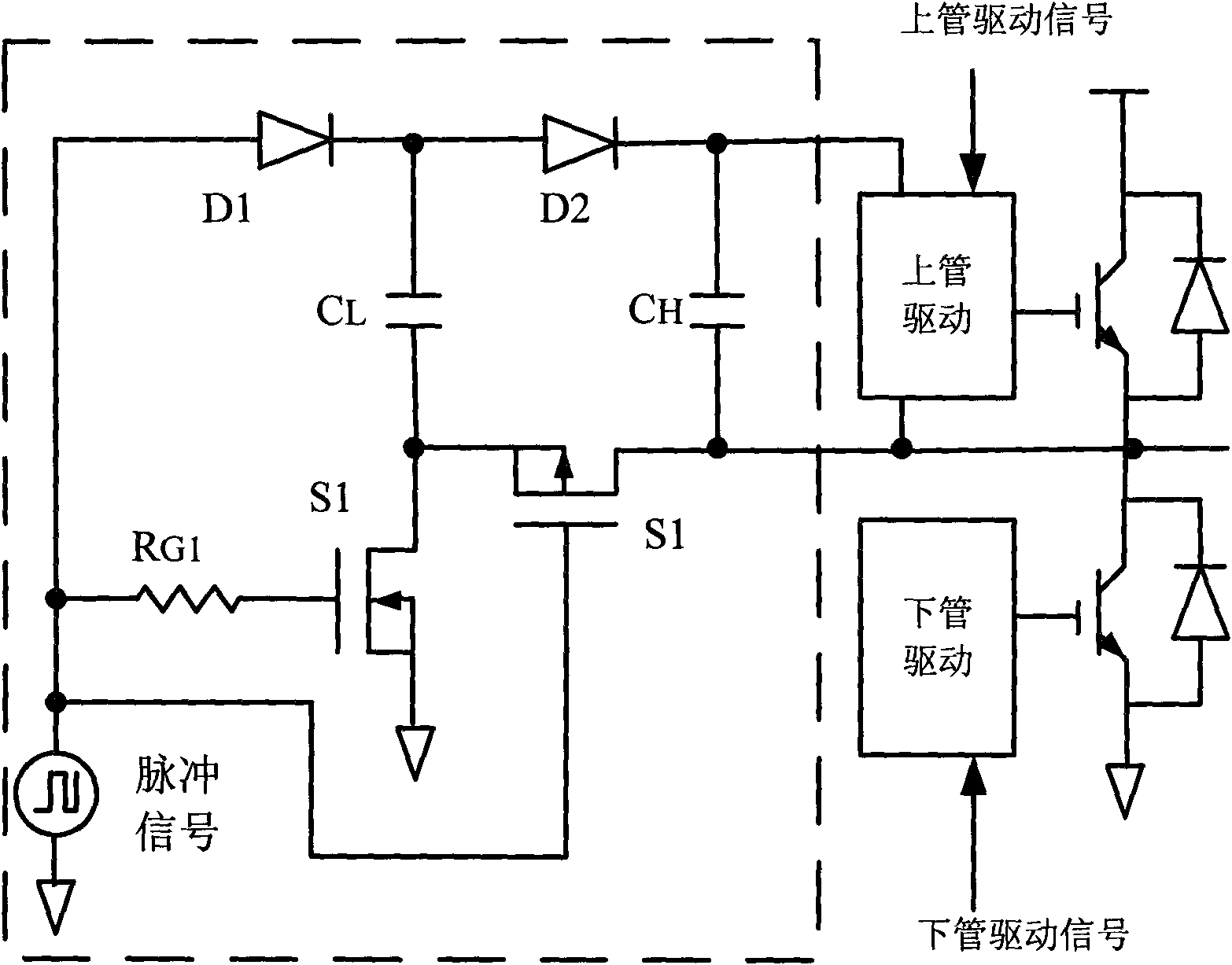

[0017] figure 2 Shown is the block diagram of each functional module inside the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com