Papermaking process tobacco sheet loosening device

A tobacco sheet and loosener technology, which is applied in the directions of tobacco, tobacco preparation, and application, can solve the problems of high labor intensity and poor loosening effect, and achieve the effects of high degree of automation, good loosening effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

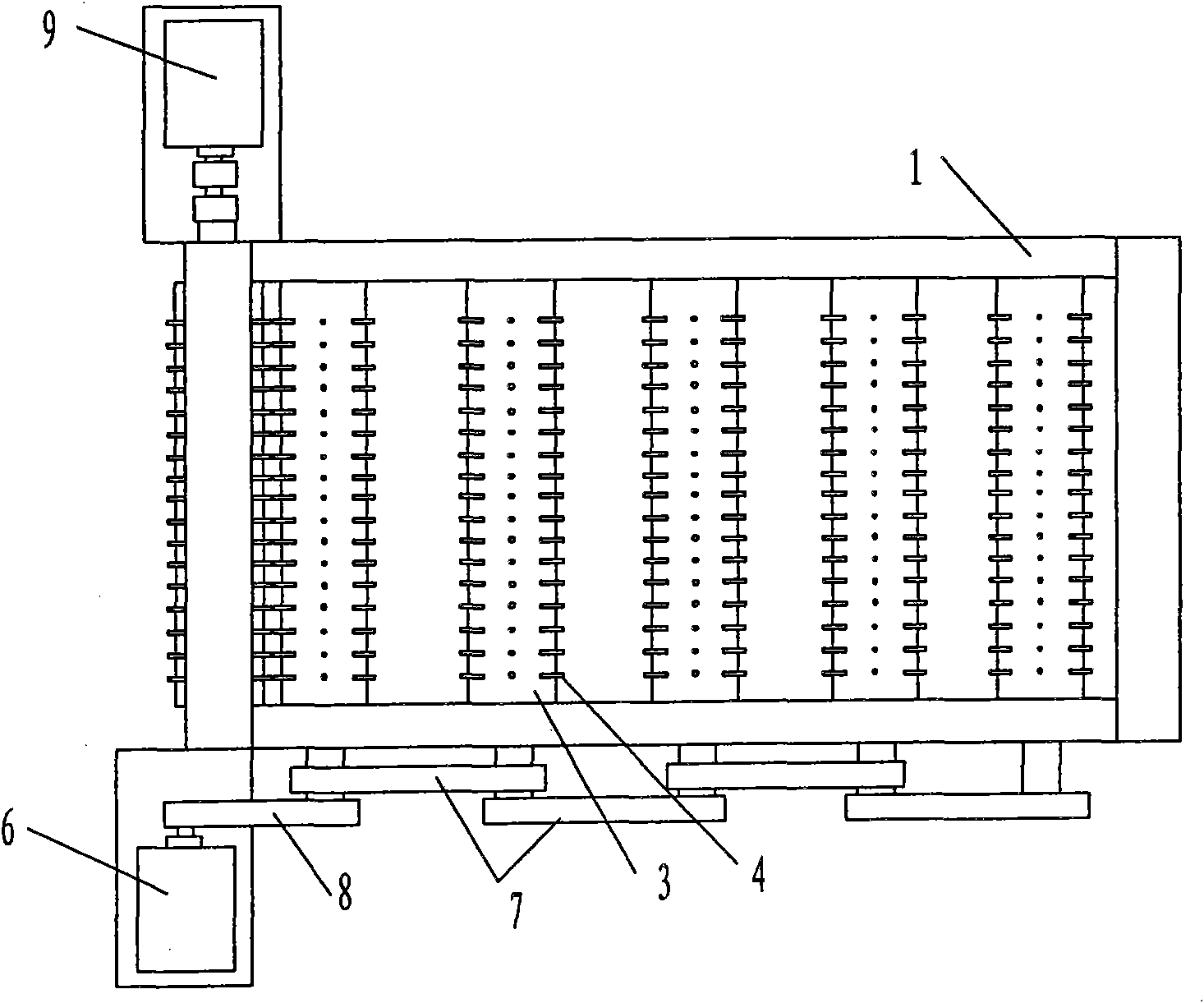

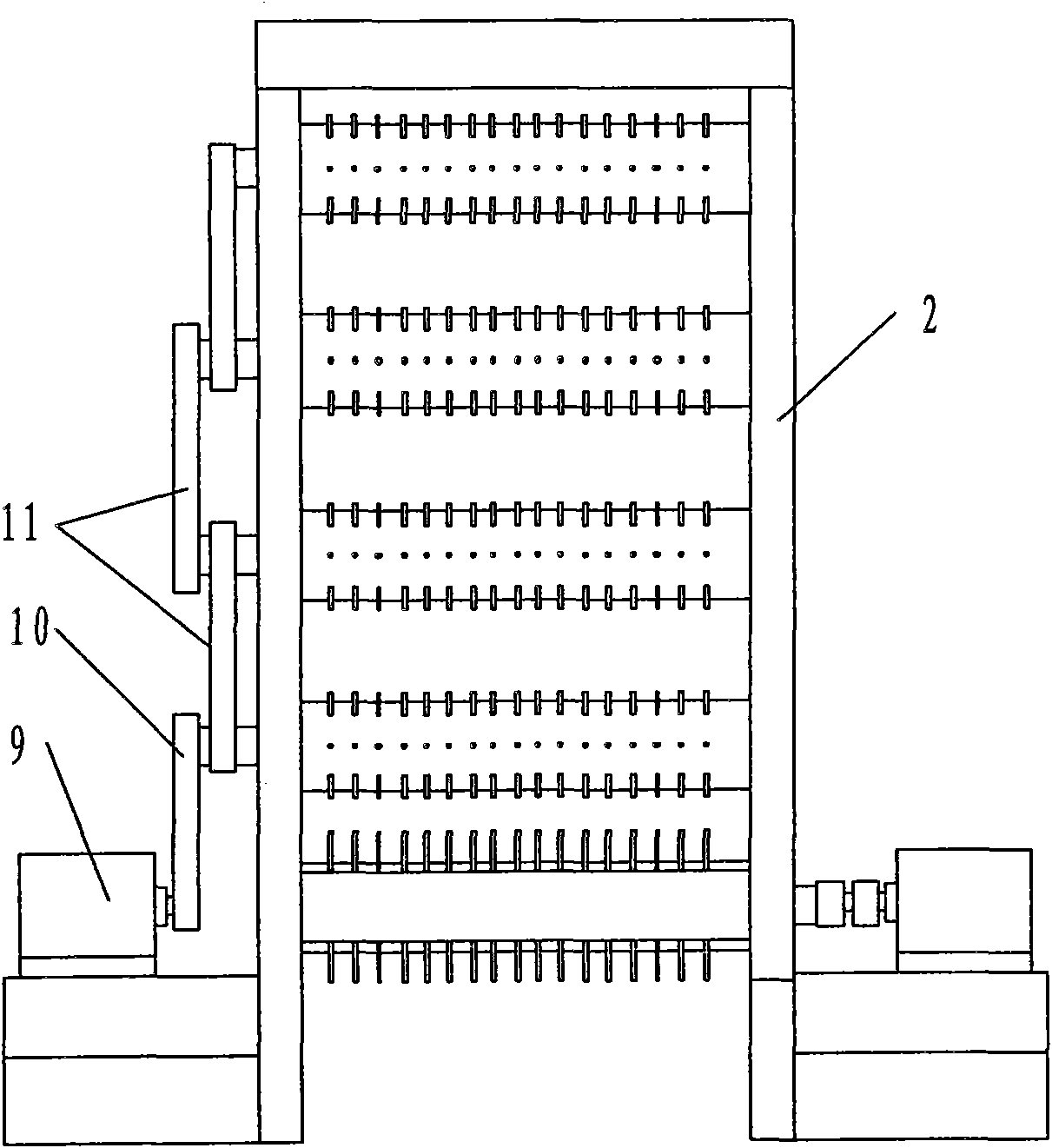

[0013] The paper-making tobacco sheet looser of the present invention includes a horizontal loosening mechanism and a vertical loosening mechanism, and the vertical loosening mechanism is connected with the horizontal loosening mechanism in a vertical state.

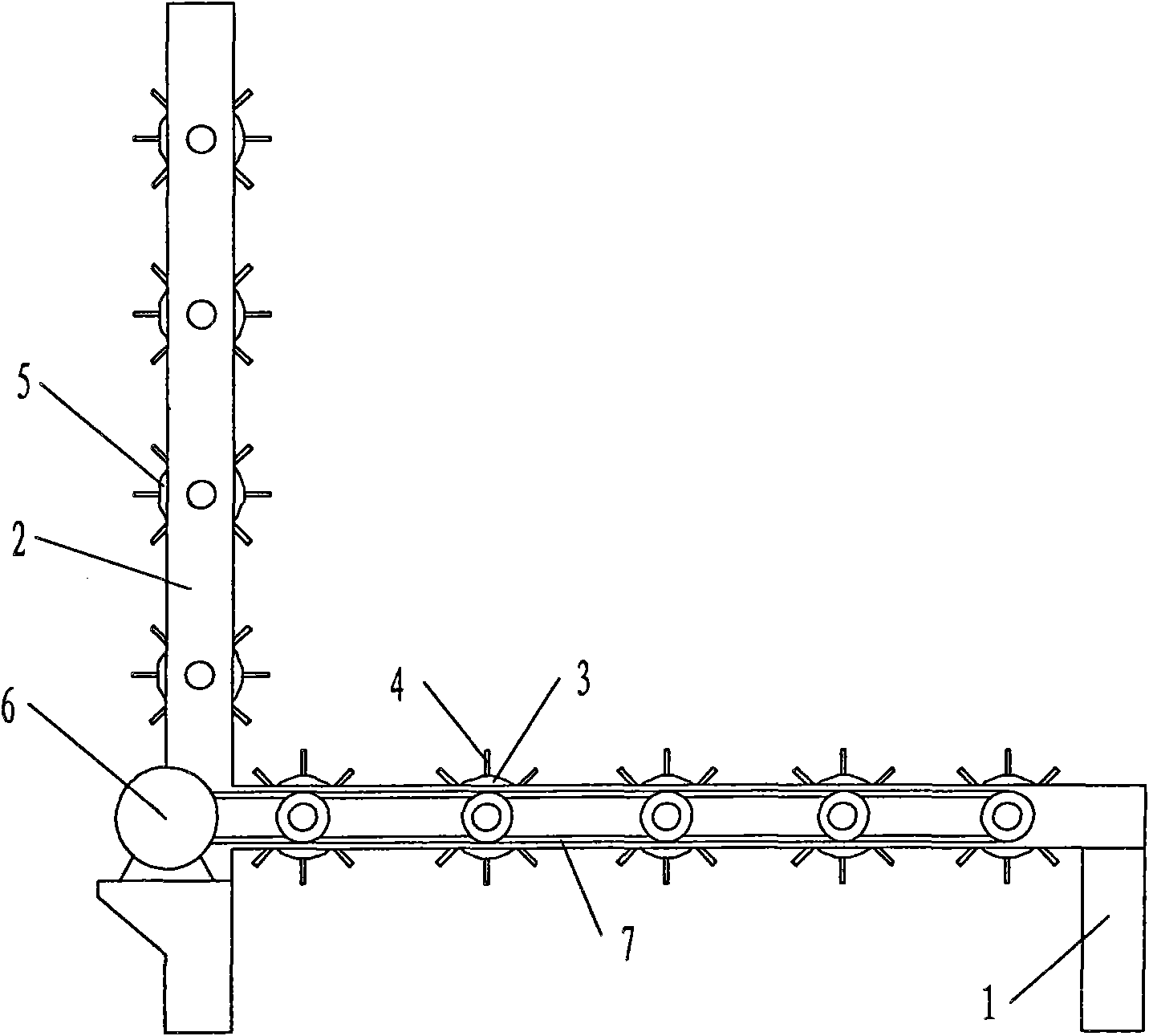

[0014] The specific structures of horizontal loose mechanism and vertical loose mechanism are as follows: figure 1 , figure 2 and image 3 As shown, the horizontal loose mechanism includes a horizontal support 1, a horizontal loose roller 3 and a horizontal transmission mechanism. A group of horizontal loose rollers 3 with loose nails 4 are installed in parallel on the horizontal support 1, and sprockets are installed on one end of each horizontal loose roller 3. The horizontal transmission mechanism is composed of a horizontal loosening motor 6, a first-level horizontal transmission chain 8 and a second-level horizontal transmission chain 7. The horizontal loosening motor 6 is connected to the first horizontal loosen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com