Full-automatic disinfection electric rice machine

An electric rice machine, fully automatic technology, applied in disinfection, cooking utensils, household utensils, etc., can solve the problems of complicated work, inability to spray and wash rice, and weak rice washing ability, so as to improve service life, reliability, and disinfection ability Overall, the effect of improving rice washing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

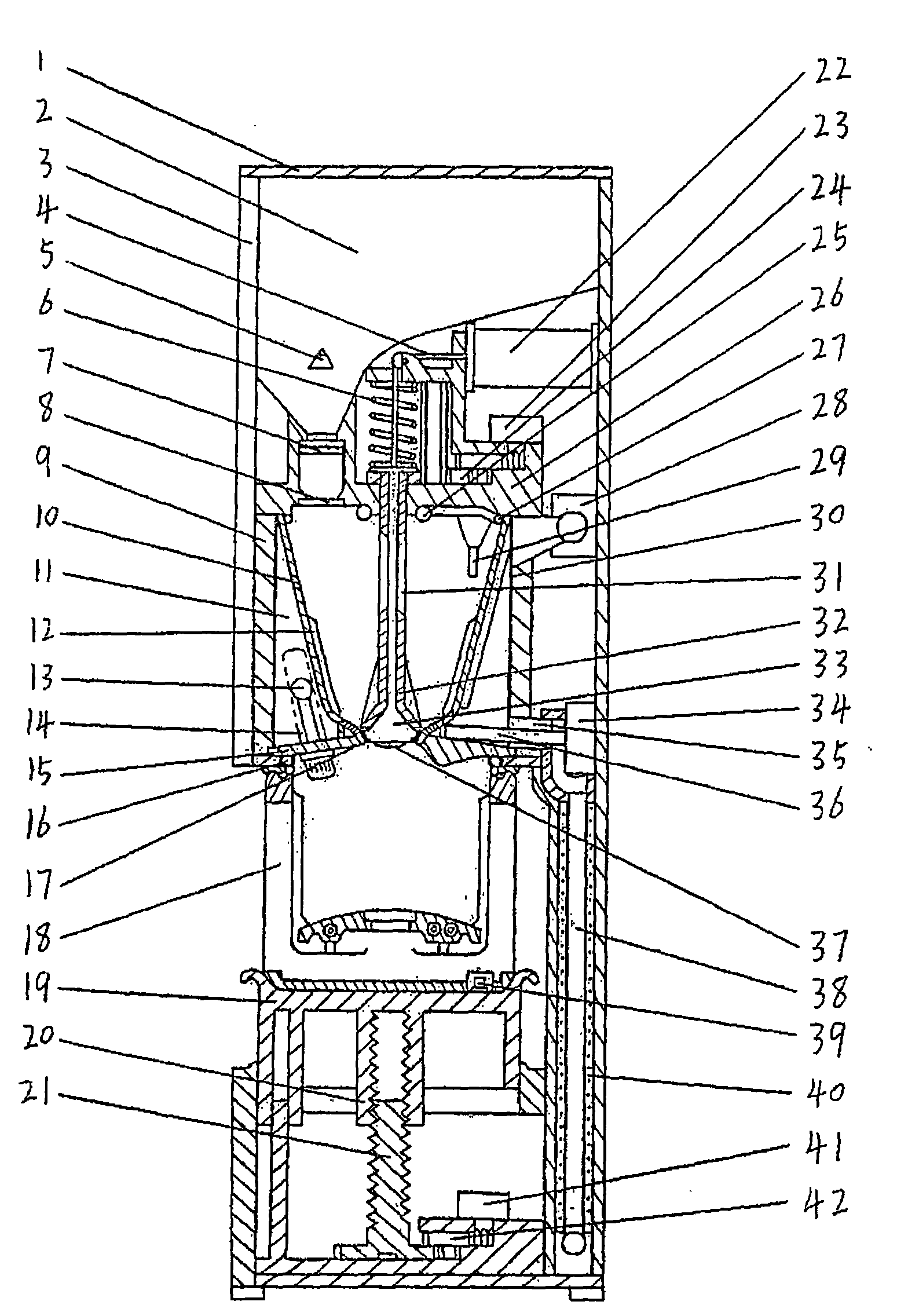

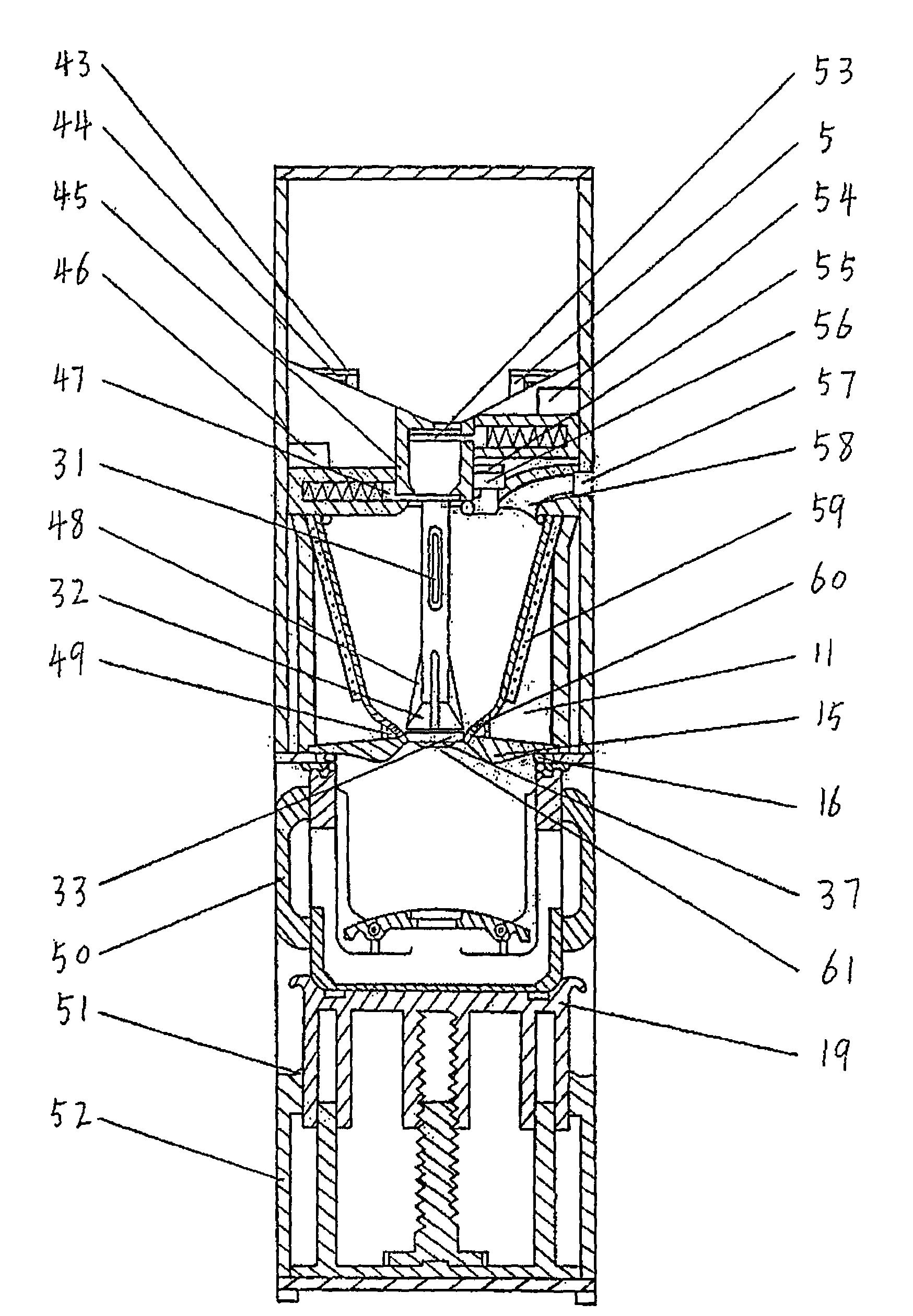

[0041] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0042] control figure 1 and figure 2 , the fully automatic sterilizing electric rice machine of the present invention is connected sequentially from top to bottom by a rice storage bin 2, a rice measuring cylinder 45, a rice washing cover 26, a rice washing device 10, a steam cover 15, a rice flushing switch 61, and an electric rice cooker 18. made.

[0043] The specific parts of the fully automatic disinfection electric rice machine include a cover 1, a rice storage bin 2, a body 3, a pulling steel wire 4, a rice shortage detector 5, a spring 6, a rice inlet gate 7, a rice discharge gate 8, and an insulation layer 9. Rice washing device 10, steam chamber 11, protruding strip 12, sealing bead 13, steam exhaust sleeve 14, steam cover 15, sealing ring 16, sealing rubber sleeve 17, electric rice cooker 18, lifting plate 19, spiral slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com