Suction nozzle cleaning tooling and using method thereof

A cleaning and tooling technology, applied in the direction of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of unusable suction nozzles, scrapping, and loss of reflective plates 11, etc., so as to reduce use costs and reduce Nozzle loss, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

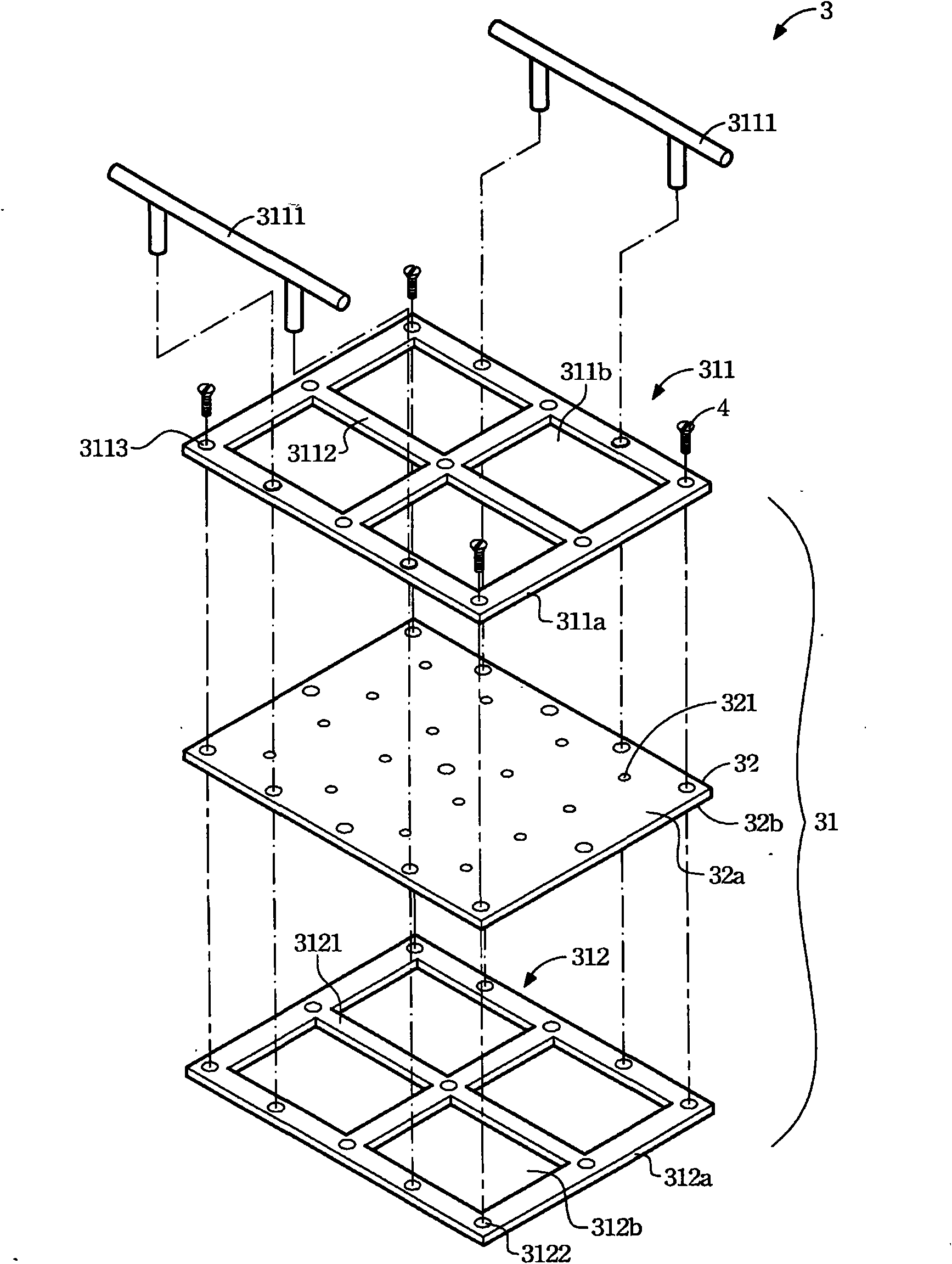

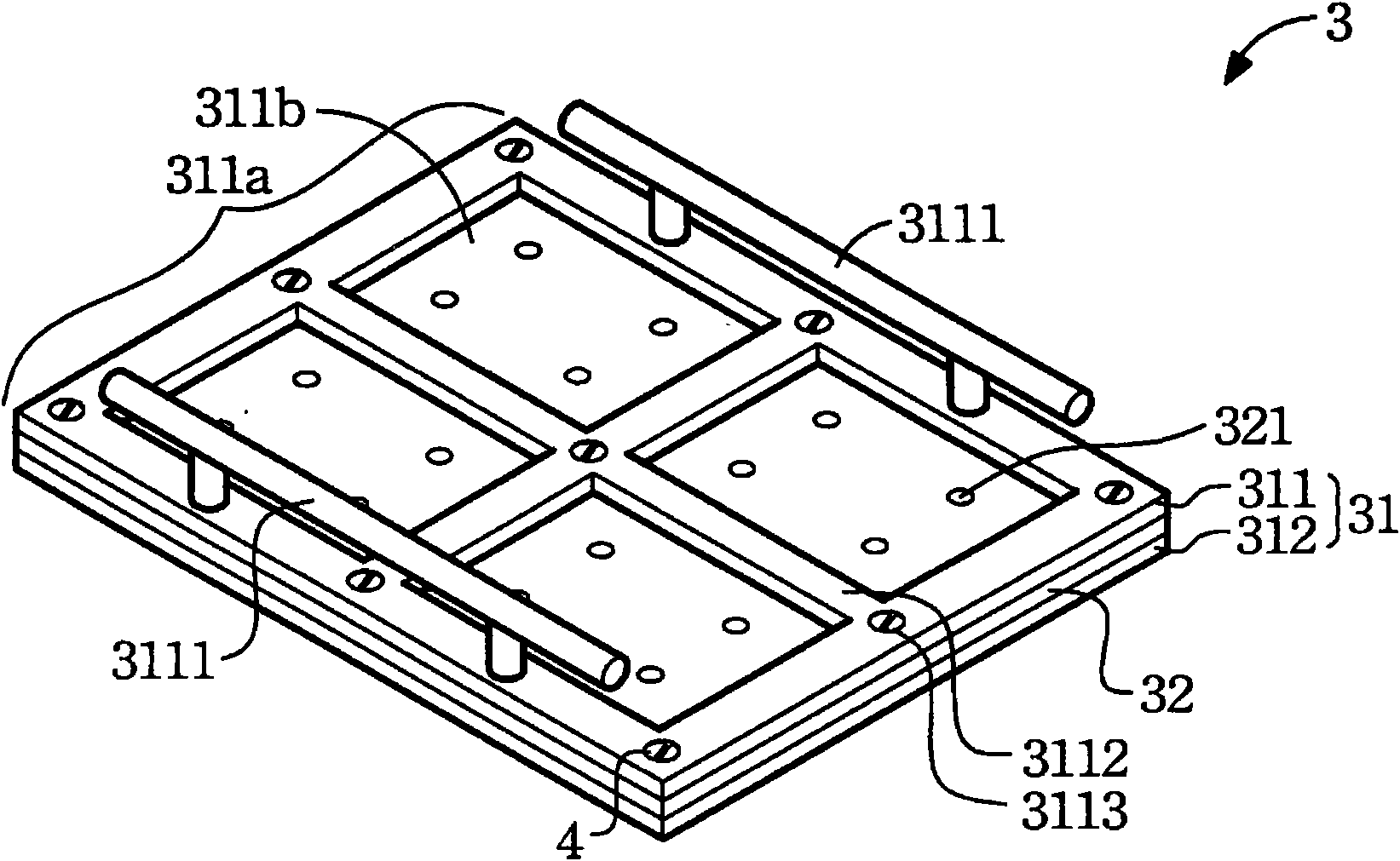

[0063] Please refer to figure 2An exploded diagram of components of the nozzle cleaning jig according to the embodiment of the present invention. As shown in the figure, the nozzle cleaning jig at least includes a frame set 31 and a sealing layer 32 . The frame set 31 includes a first frame 311 and a second frame 312. The two frames 311, 312 are respectively composed of a plurality of frame bars 311a, 312a, and a hollow area 311b, 312b is formed between them.

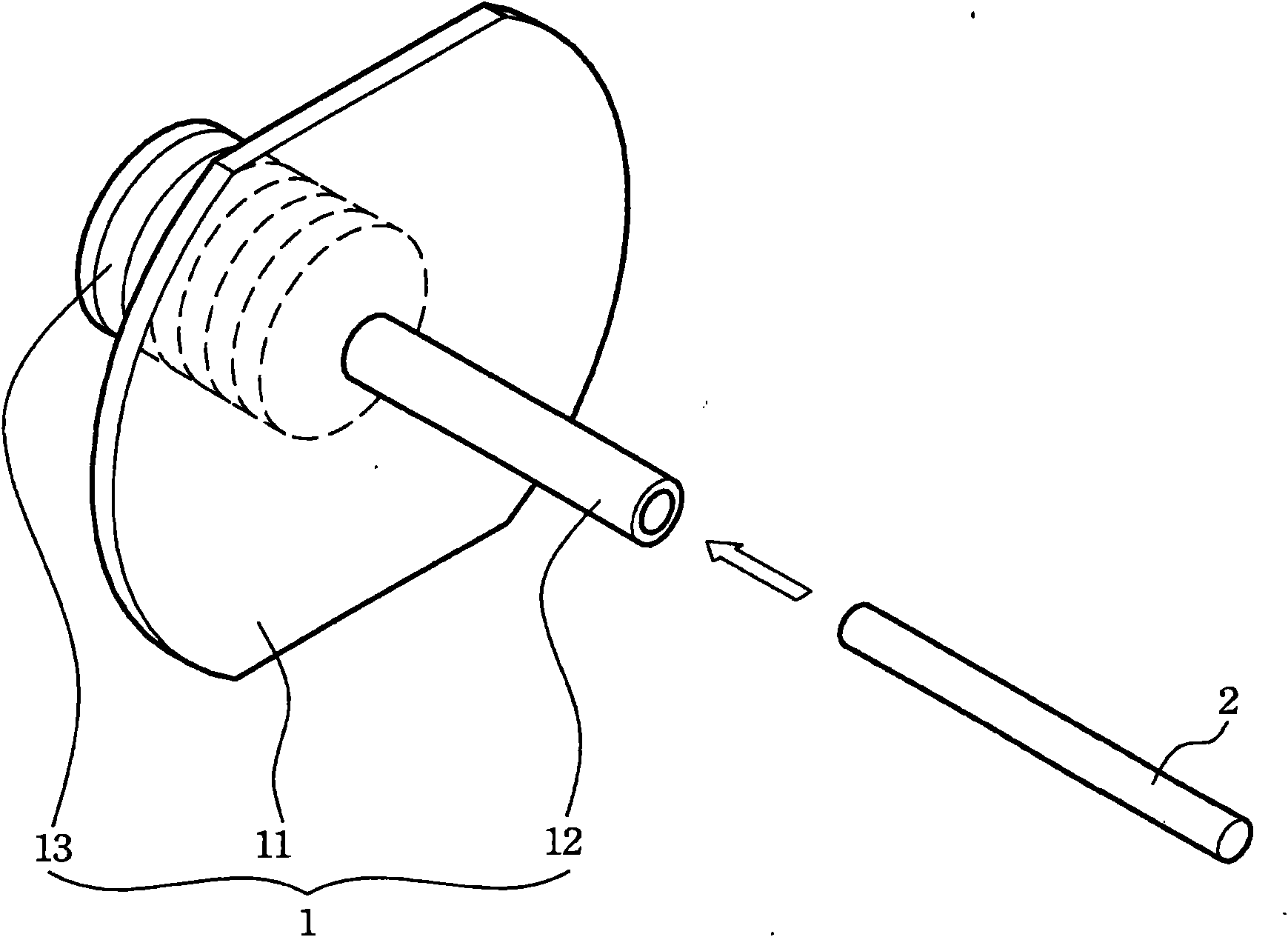

[0064] The surrounding edges of the sealing layer 32 are clamped between the first frame 311 and the second frame 312, and the middle area thereof is exposed through the hollow areas 311b, 312b of the frame group 31, and a hole 321 is provided to allow the suction nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com