Method for loading and unloading steel plate of small-hatch ship

A technology for small hatches and steel plates, which is applied in the field of port cargo handling, can solve the problems of unsafe, difficult horizontal entry of steel plates, and low loading efficiency, and achieves the effects of strong applicability, improved loading efficiency, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

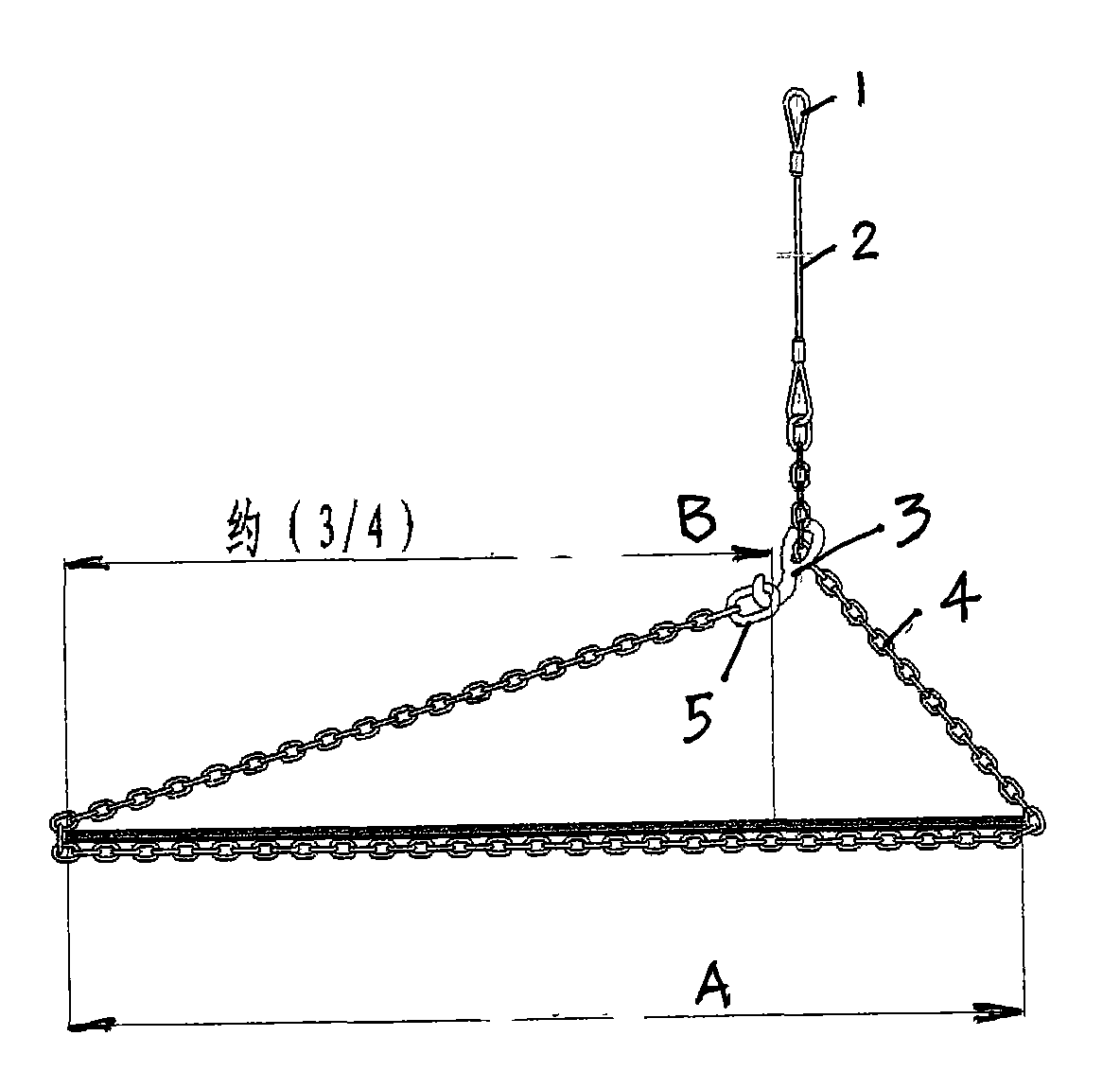

[0016] A steel plate loading and unloading operation method for ships with small hatches, which uses special hook chains to replace the steel plate spreader used in conventional steel plate operations, and adopts the hoisting method of eccentric lashing cables, so that the steel plate surface and the horizontal plane form an angle after the steel plate is hoisted. At this time, the lower side of the steel plate is first to enter the hatch along the diagonal direction of the hatch, and then hooked along the trend to place the steel plate firmly in the cabin.

[0017] Such as figure 1 The special hook chain shown is: a wire rope sling 2 with a ring-shaped suspension nose 1 at both ends, one end of the chain 4 is connected to the ring-shaped suspension nose at one end, the other end of the chain is connected to the end ring 5, and there is a Sliding hook 3 that can move freely.

[0018] In response to this situation, according to the structural characteristics of the cabin and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com