Multitube fiber-optic coupling method of symmetrical semiconductor laser

A technology of semiconductors and lasers, applied in the coupling of optical waveguides, instruments, optics, etc., can solve the problems of small number of integrations and low space utilization, and achieve the effects of simplified design, increased number of integrations, and high laser brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

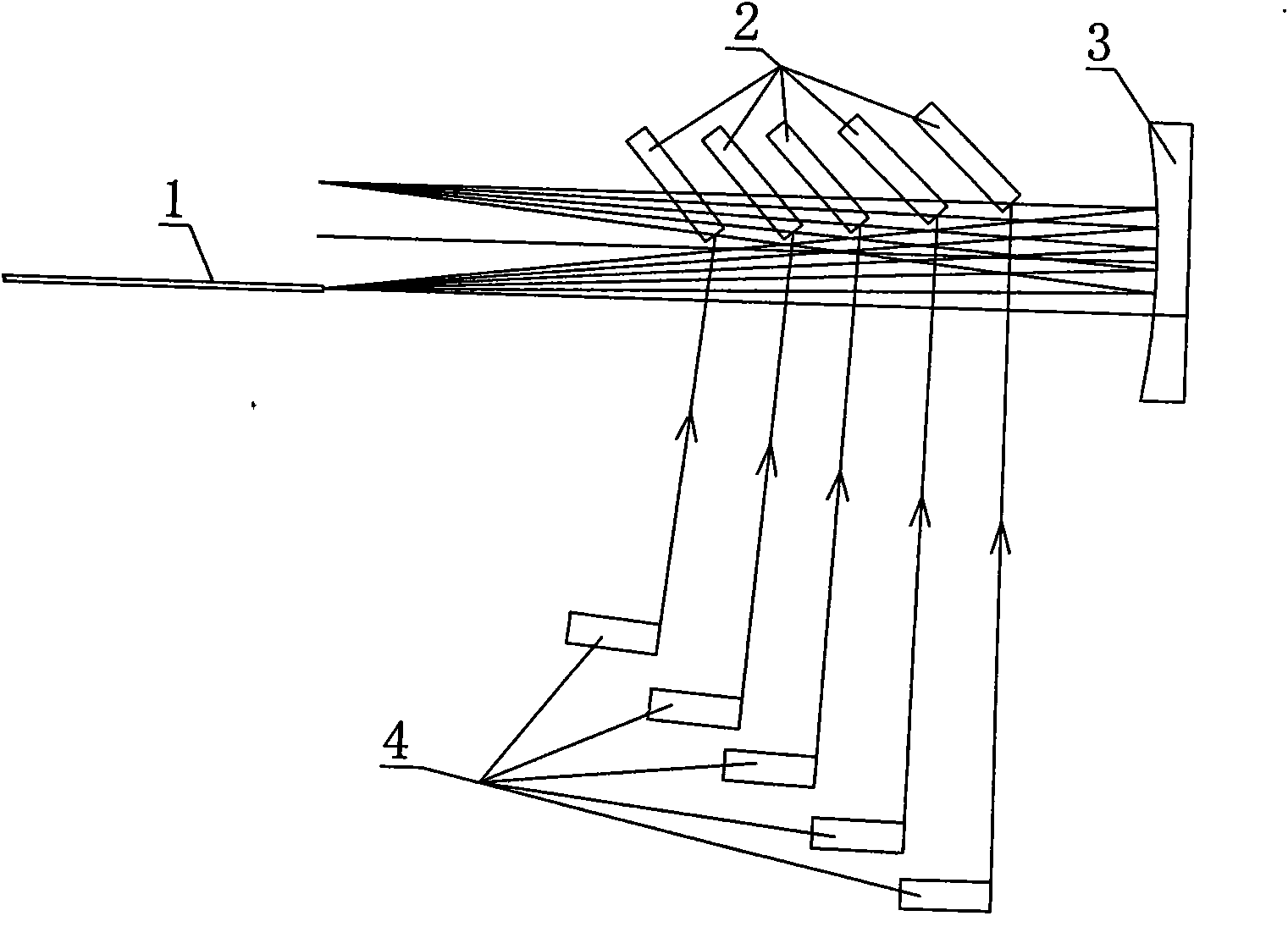

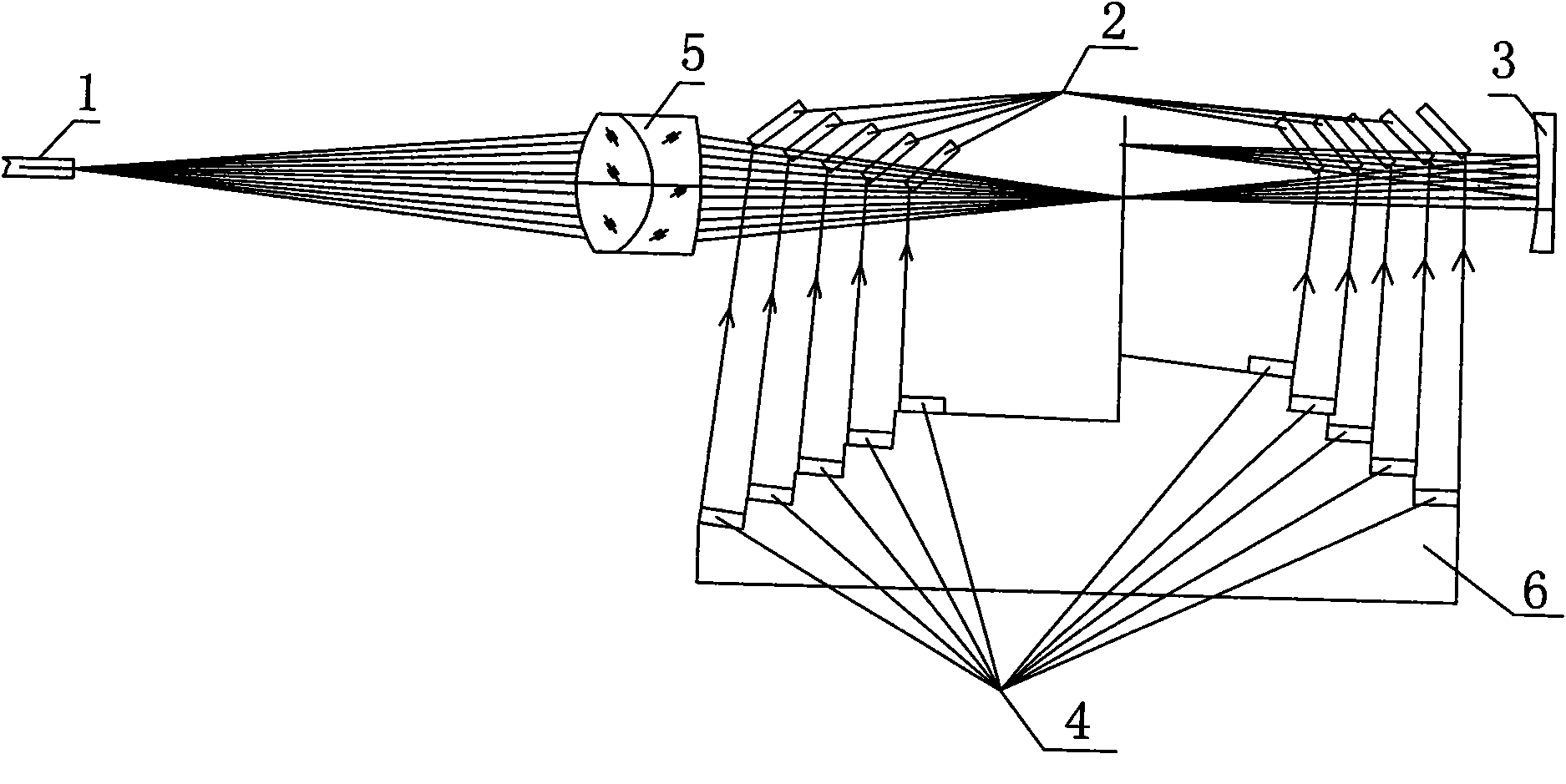

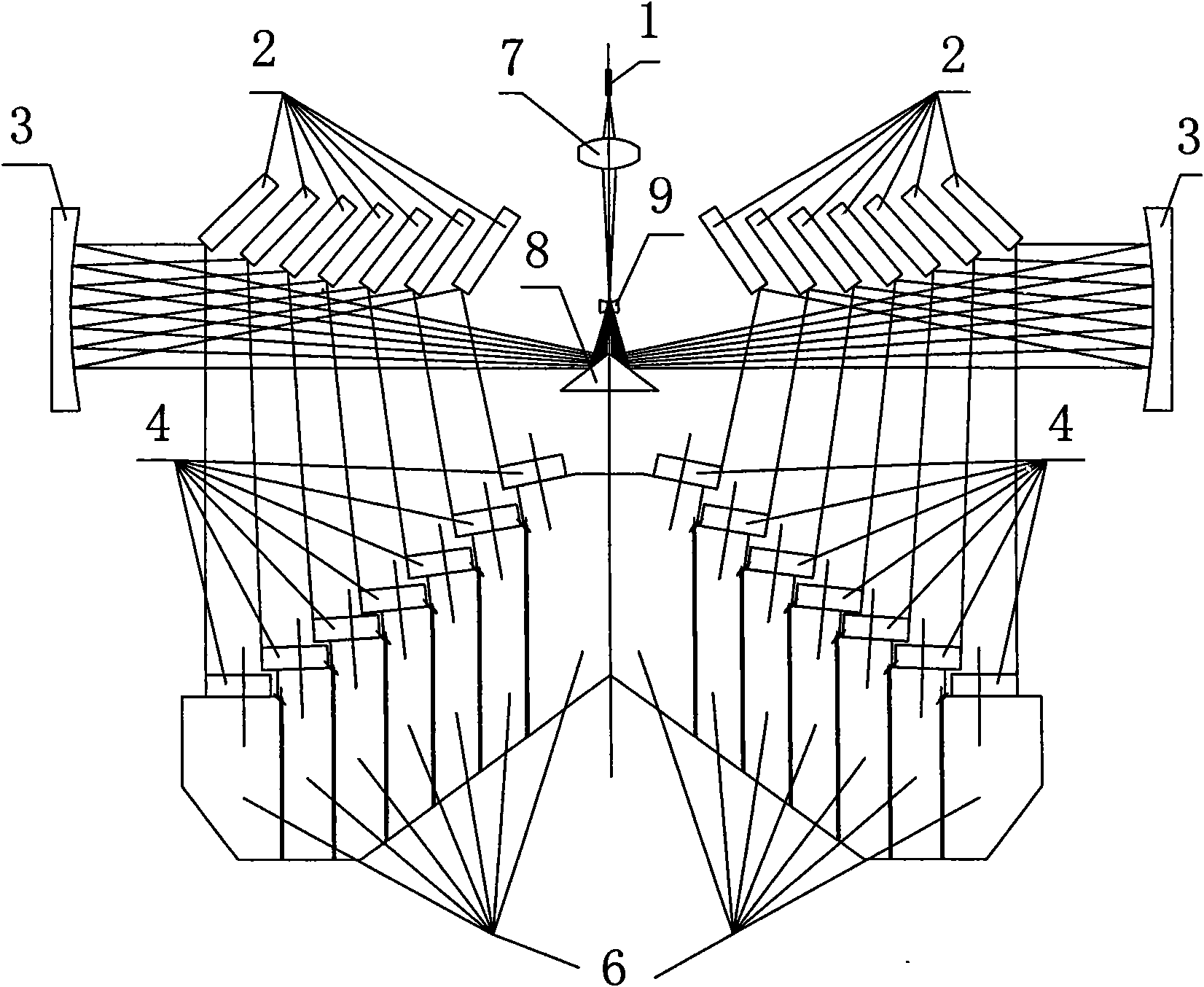

[0015] The beam integration method of the present invention is as image 3 As shown, the optical path is divided into two symmetrical parts. First, a cylindrical lens is used to compress the fast-axis divergence angle of each semiconductor laser 4 so that the fast-axis divergence angle is less than or equal to 1 degree. Then each semiconductor laser 4 is fixed on the laser seat 6, the laser seat 6 is divided into two parts with symmetrical left and right positions, and they are relatively insulated, so that each semiconductor laser can be connected in series to supply power. Each semiconductor laser 4 corresponds to a 45-degree reflector 2 . The light emitted by each semiconductor laser 4 in the left part is reflected on the same concave reflector 3 through the 45-degree reflector 2, and each 45-degree reflector and its corresponding concave reflector are adjusted so that the light spots are gathered on a plated At the same point before the top of the prism 8 of the all-refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com