Notebook computer

A technology for notebook computers and electronic components, which is used in electrical digital data processing, instruments, digital data processing components, etc., and can solve the problems of user discomfort and high temperature on the upper surface of the casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

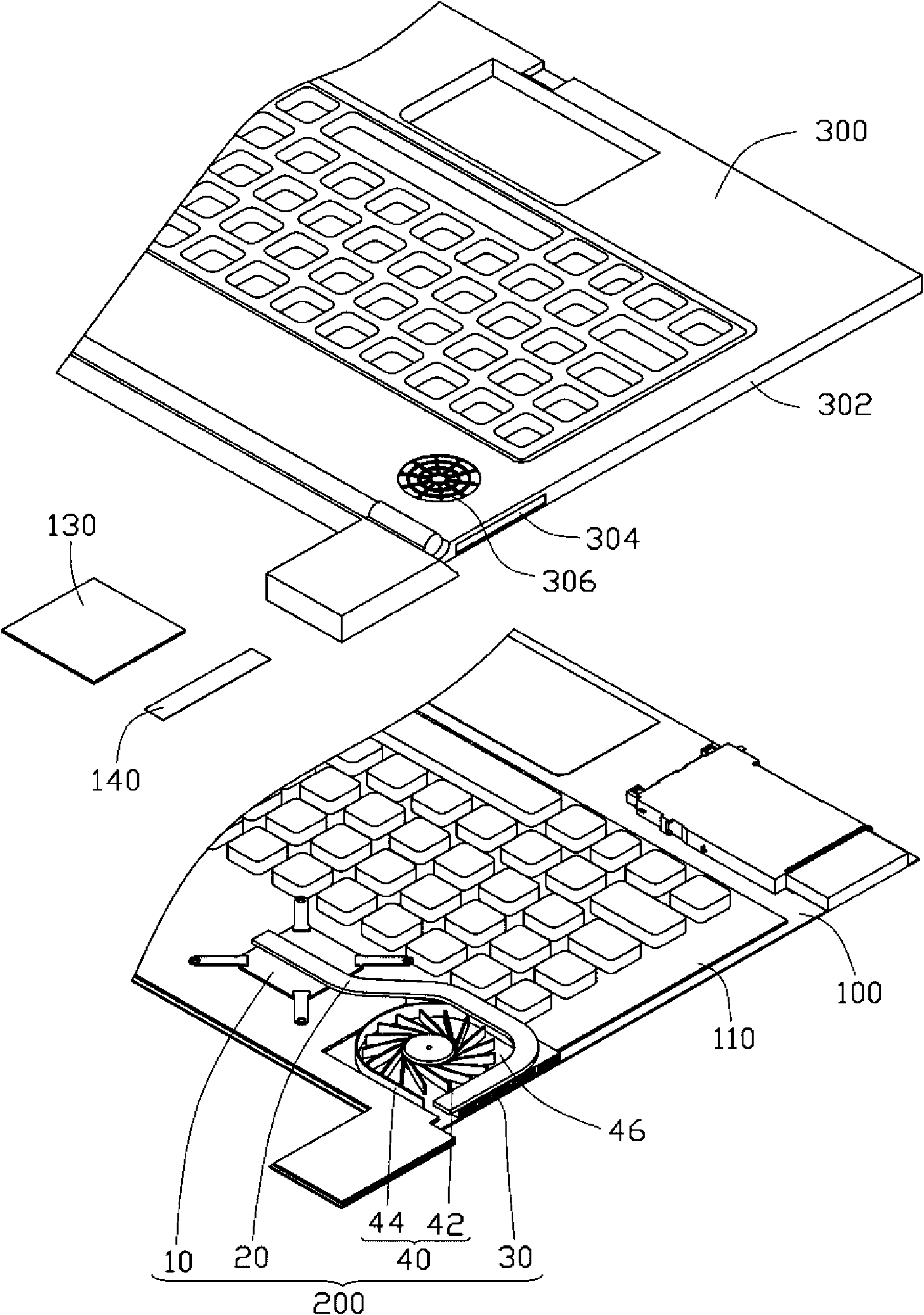

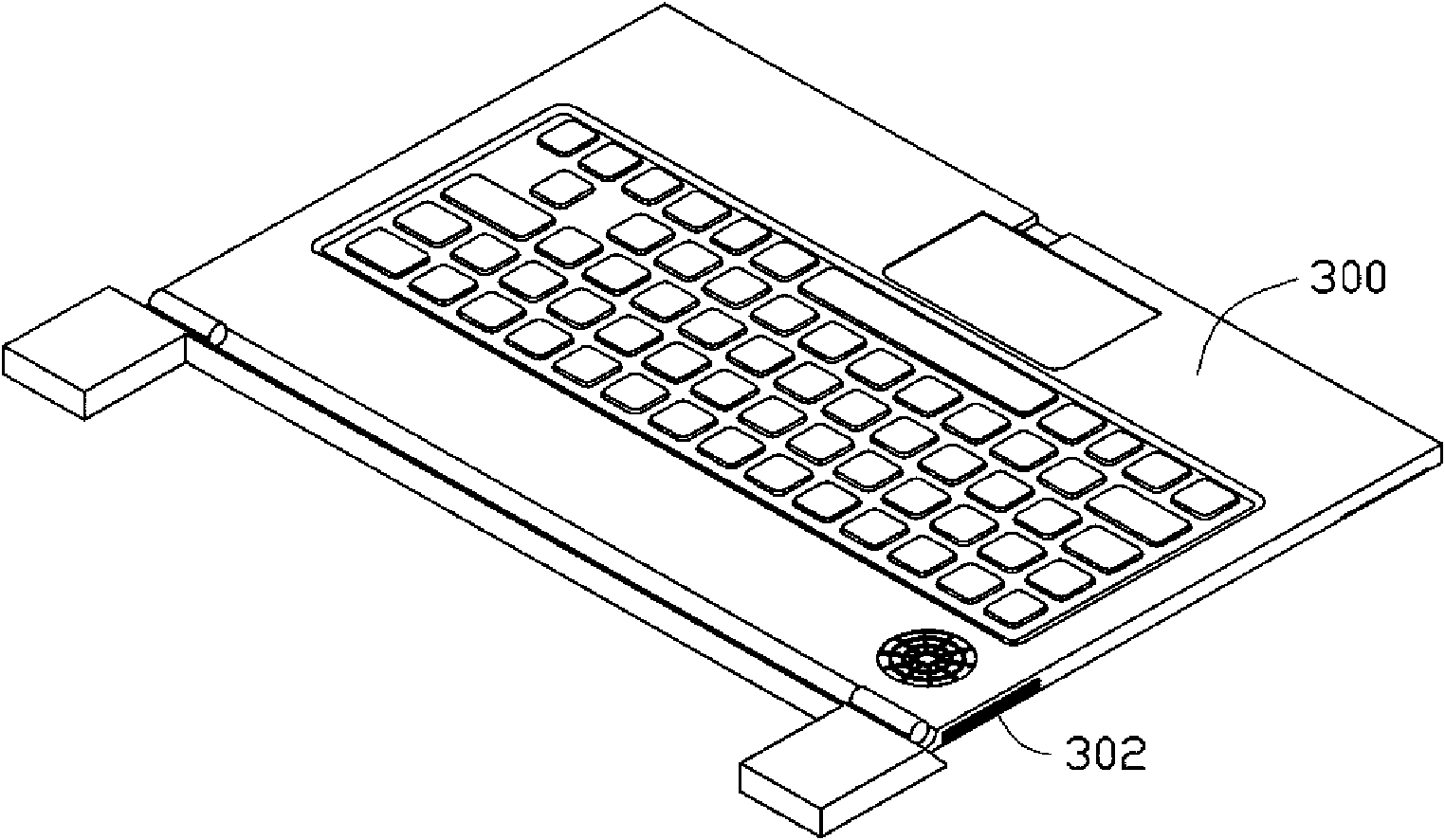

[0011] See figure 1 and figure 2 , Are respectively a three-dimensional exploded view and an assembly view of an embodiment of the notebook computer of the present invention. The notebook computer includes a base plate 100, a heat dissipation device 200 on the base plate 100, and a cover plate 300 covering the base plate 100. For brevity, the display screen of the notebook computer is omitted in the figure.

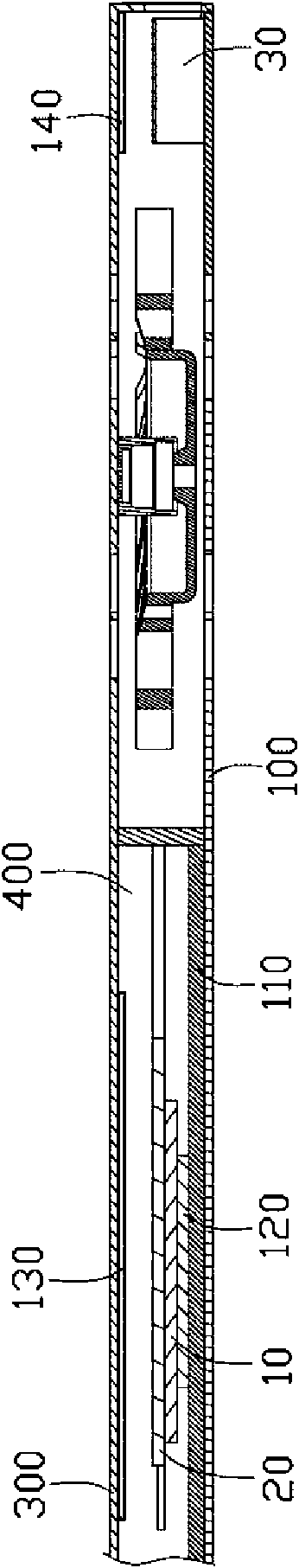

[0012] Please refer to image 3 The notebook computer further includes a circuit board 110 disposed on the bottom plate 100, a heat-generating electronic component 120 disposed on the circuit board 110, a first vacuum heat insulation board 130, and a second vacuum heat insulation board 140. The bottom plate 100 and the cover plate 300 combine to form a receiving space 400. The circuit board 110, the heating electronic component 120, the first and second vacuum insulation boards 130 and 140 and the heat dissipation device 200 are accommodated in the accommodation space 400. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap