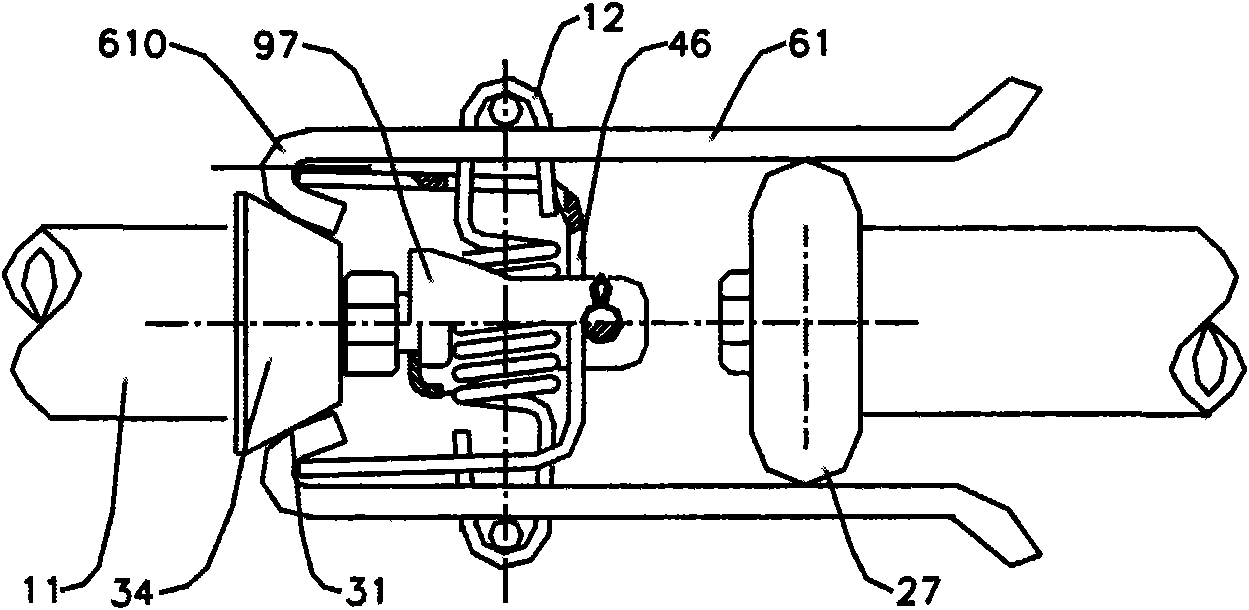

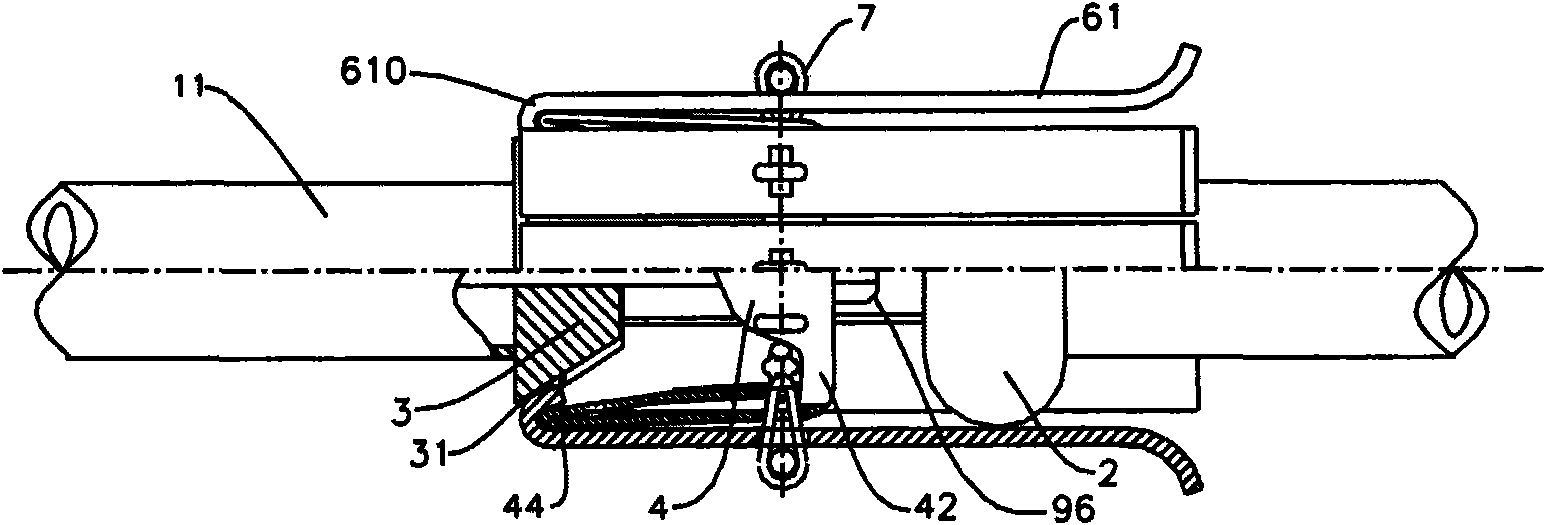

Contact assembly of isolating switch

A technology of contact assembly and isolation switch, which is applied in the directions of air switch parts, contact meshing, etc., can solve the problems of difficult processing of spring components, limitation of contact pressure, limitation of spring elastic coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

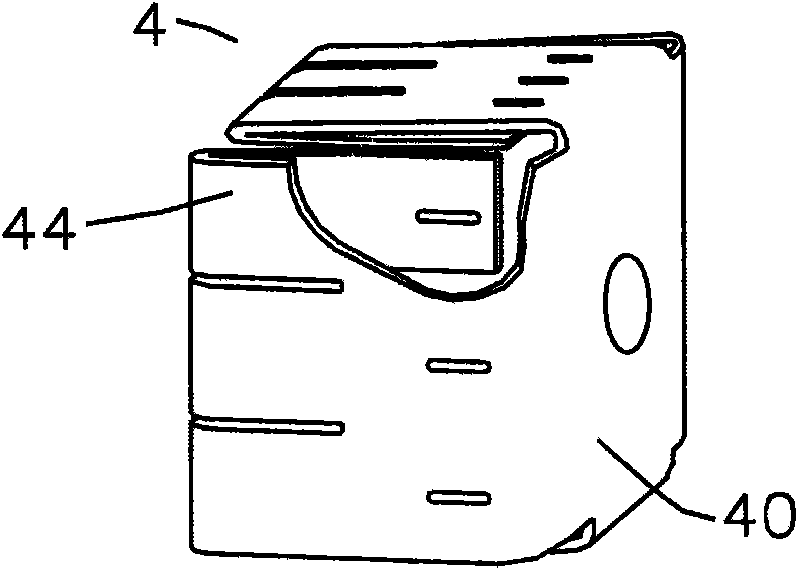

[0054] Refer to the attached Figure 8-1 0. Describe in detail the contact assembly according to the second preferred embodiment of the present invention. The difference between the second preferred embodiment and the first preferred embodiment described above lies in the spring member, therefore, only the difference between the two will be described below.

[0055] The spring member of the contact assembly according to this embodiment includes two U-shaped leaf springs 81 and 82, such as Figure 10A with 10B Shown, and, two plate springs 81 and 82 intersect with each other, and the U-shaped bottom of the first U-shaped plate spring 81 is provided with a hole 811, so that the coupling rod 9 passes through the hole 811, and connects with the second U-shaped spring 81. The U-shaped bottom of the leaf spring 82 is connected. Such as Figure 10C As shown, one end connected with the second U-shaped leaf spring 82 of the connecting rod 92, hereinafter referred to as the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com