Mounting nut of prestressed steel bar

A technology for prestressed steel bars and nuts, applied in the direction of molds, etc., can solve the problems of low installation efficiency of prestressed steel bars and anchor pads, inaccurate axial installation positions of prestressed steel bars and anchor pads, etc. Simple and reliable, easy to construct and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

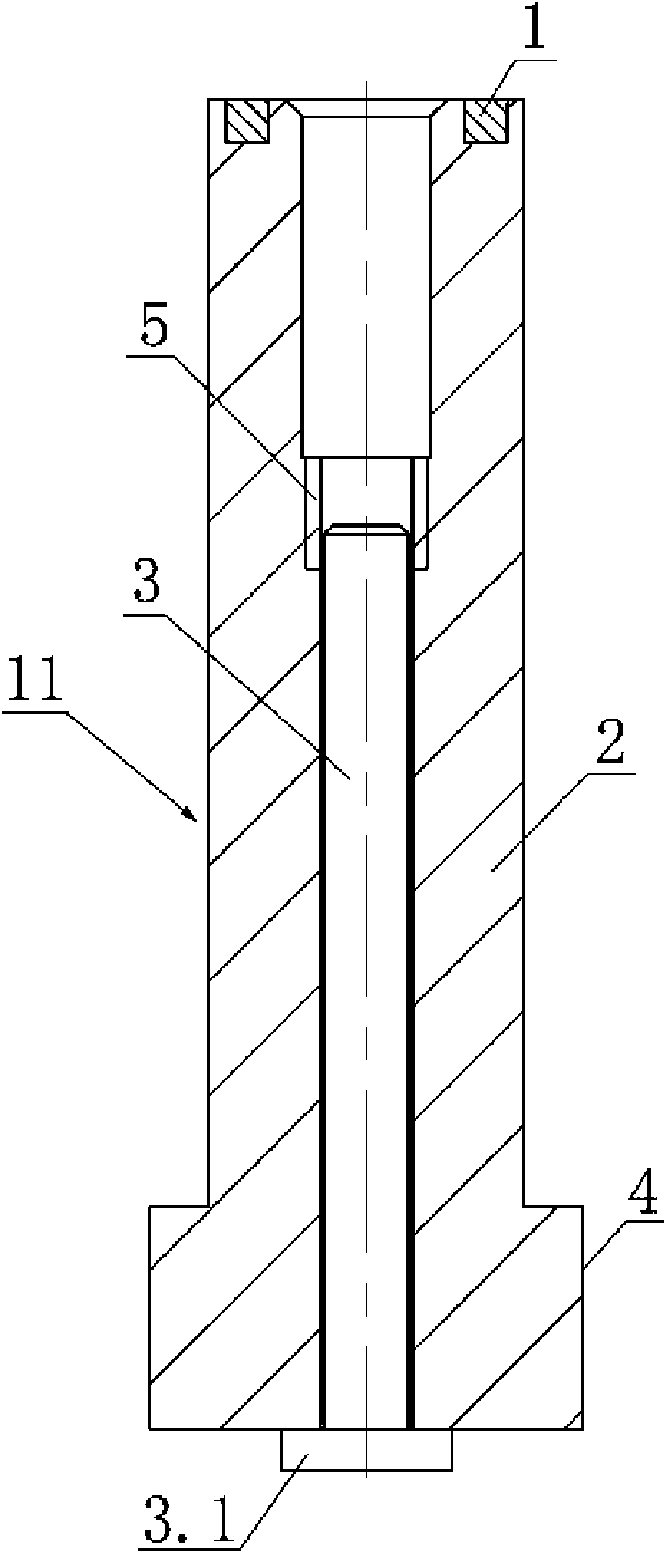

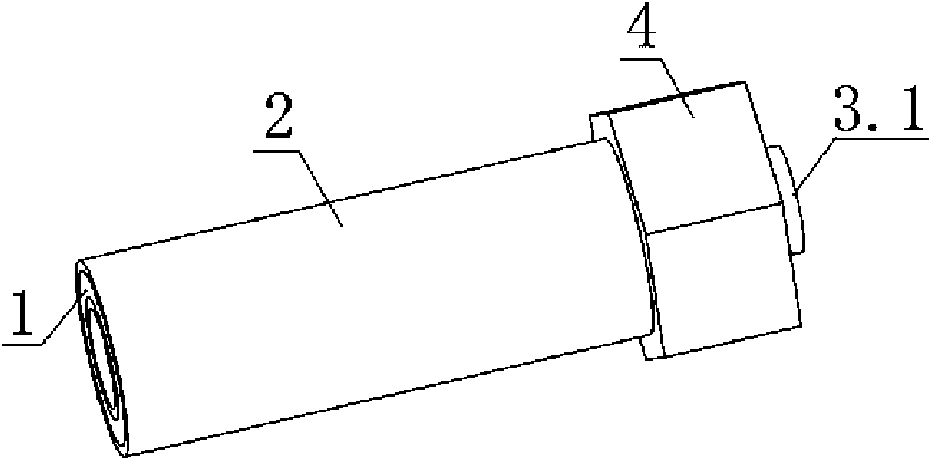

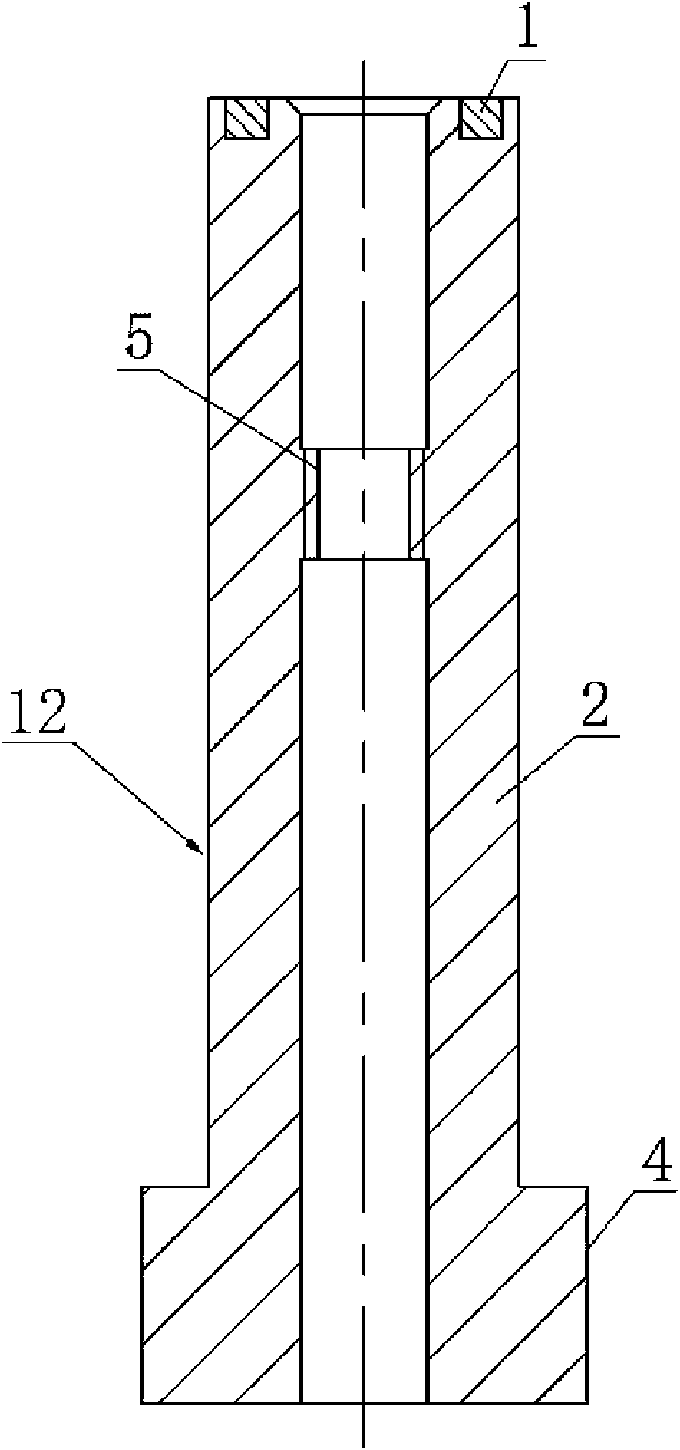

[0018] Examples see Figure 4 As shown, this prestressed steel rod mounting nut includes a fixed end mounting nut 11 and a tensioning end mounting nut 12. Both the fixed end mounting nut and the tensioning end mounting nut have a threaded sleeve, and the inner diameter of the threaded sleeve is slightly larger than The diameter of the prestressed steel rod 10, there is a section of thread 5 in the middle of the inner wall of the threaded casing, and a magnetic ring 1 is concentrically embedded on the end surface of the tail of the threaded casing. A positioning surface is formed on one side, and a positioning column 3 with a positioning column end 3.1 is fixed inwardly to the threaded section of the sleeve end of the mounting nut at the fixed end, and the positioning column end 3.1 of the positioning column is connected to the sleeve end of the threaded sleeve. Solder connection between header 4.

[0019] The end 4 is a square head, a hexagonal head or a hexagonal cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com