Fabricated modular house structure

A modular and prefabricated technology, applied in heating methods, building components, building structures, etc., to achieve the effects of improving earthquake resistance, increasing prefabrication speed, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

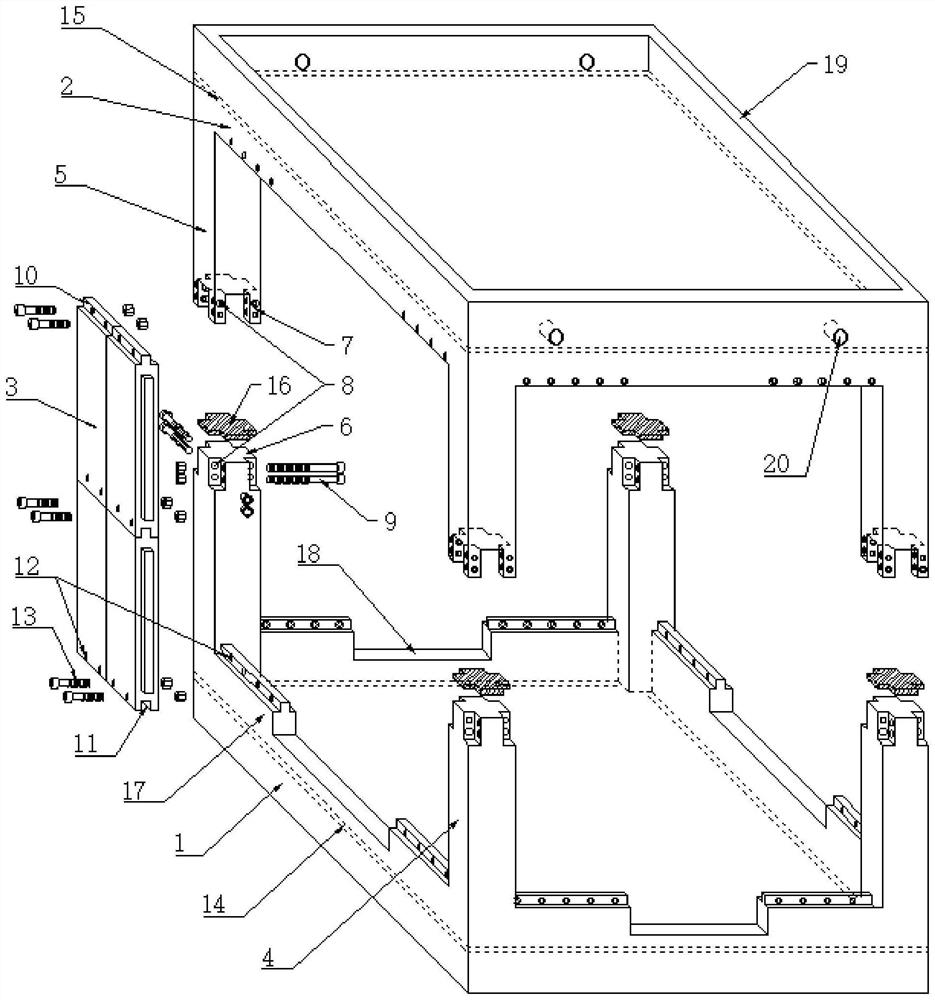

[0024] Such as figure 1 As shown, a prefabricated modular house structure includes a floor 1, a roof 2, and a plurality of beams and columns and multiple wall panels 3 supported between the floor and the roof. The column 4 and the upper half column 5 are composed, wherein, the lower half column is integrally fixed with the floor, the upper half column is integrally fixed with the roof, and the upper end of the lower half column is integrally provided with a flower joint-6, The lower end of the upper half column is integrally provided with a flower joint 2 7 that is mated with the flower joint 1. The flower joint 1 is an outwardly protruding cross-shaped male head, and the flower joint 2 is A concave cross-shaped female head, and the plug-in ends of the first flower joint and the second flower joint are provided with a bolt through hole 8, and the first flower joint and the second flower joint are fastened by a bolt 9 connection; the wallboards on each side are formed by faste...

Embodiment 2

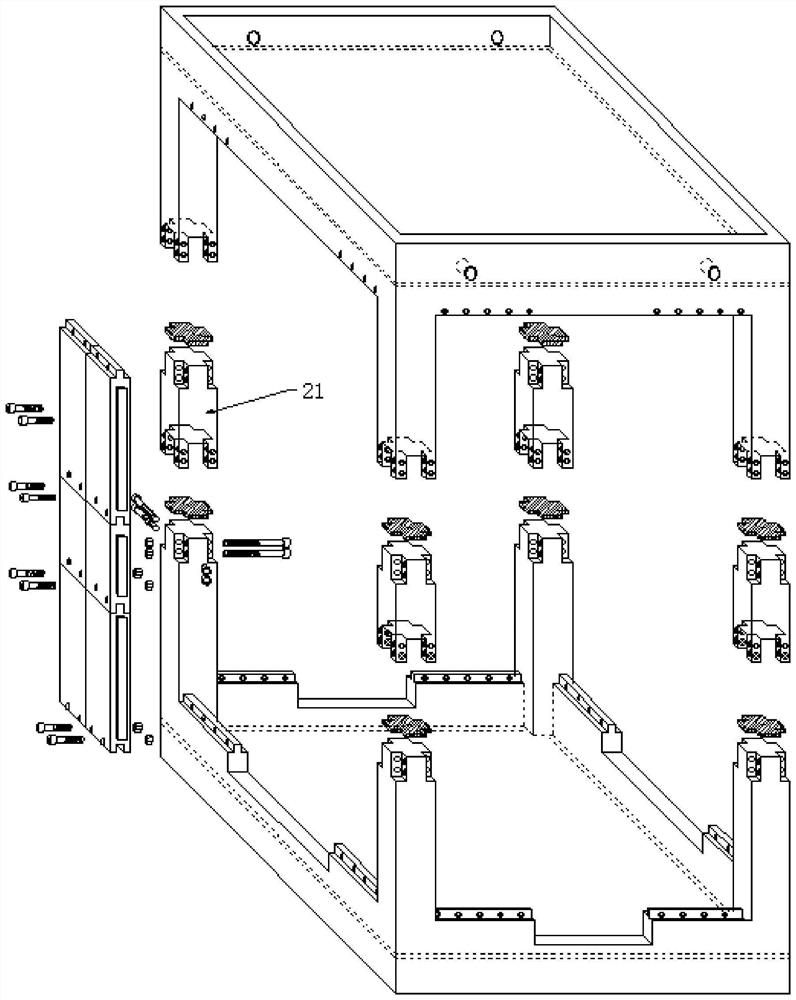

[0032] Such as figure 2As shown, a prefabricated modular house structure includes a floor 1, a roof 2, and a plurality of beams and columns and multiple wall panels 3 supported between the floor and the roof. The column 4 and the upper half column 5 are composed, wherein, the lower half column is integrally fixed with the floor, the upper half column is integrally fixed with the roof, and the upper end of the lower half column is integrally provided with a flower joint-6, The lower end of the upper half column is integrally provided with a flower joint 2 7 that is mated with the flower joint 1. The flower joint 1 is an outwardly protruding cross-shaped male head, and the flower joint 2 is A concave cross-shaped female head, and the plug-in ends of the first flower joint and the second flower joint are provided with a bolt through hole 8, and the first flower joint and the second flower joint are fastened by a bolt 9 connection; the wallboards on each side are formed by faste...

Embodiment 3

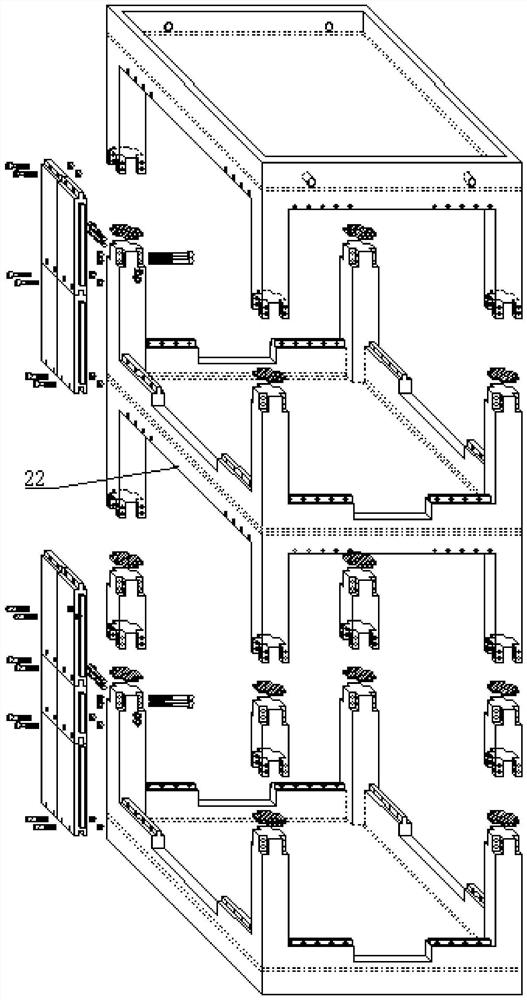

[0041] Such as image 3 As shown, a prefabricated modular house structure includes a floor 1, a roof 2, and a plurality of beams and columns and multiple wall panels 3 supported between the floor and the roof. The column 4 and the upper half column 5 are composed, wherein, the lower half column is integrally fixed with the floor, the upper half column is integrally fixed with the roof, and the upper end of the lower half column is integrally provided with a flower joint-6, The lower end of the upper half column is integrally provided with a flower joint 2 7 that is mated with the flower joint 1. The flower joint 1 is an outwardly protruding cross-shaped male head, and the flower joint 2 is A concave cross-shaped female head, and the plug-in ends of the first flower joint and the second flower joint are provided with a bolt through hole 8, and the first flower joint and the second flower joint are fastened by a bolt 9 connection; the wallboards on each side are formed by faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com