Prefabricating tool for triple connecting pipe of heat collecting pipe of trough type photo-thermal power station

A technology of photothermal power stations and heat collector tubes, applied in the direction of manufacturing tools, applications, auxiliary devices, etc., to achieve the effects of facilitating product protection, improving prefabrication speed, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

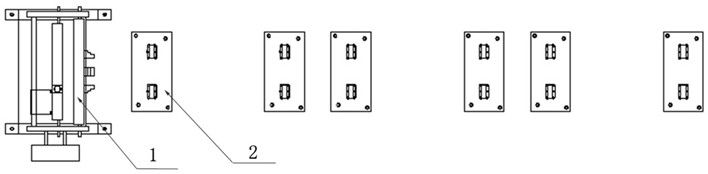

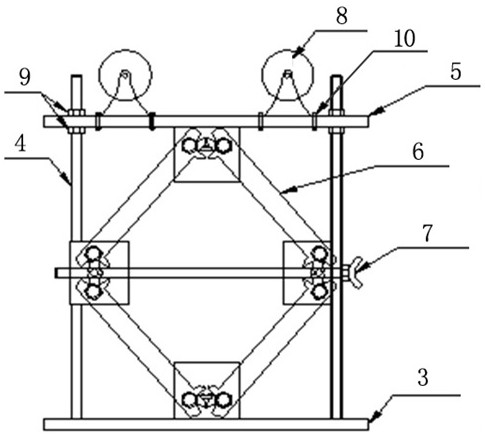

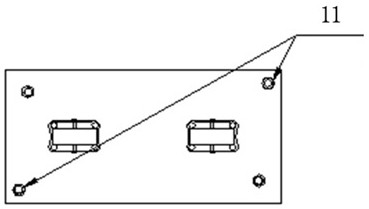

[0025] Such as figure 1 As shown, the present invention relates to a prefabricated tooling for three-connected heat collector tubes of a trough-type photothermal power station. The tooling mainly includes a welding positioner 1 and several adjustable lifting and rolling tables 2, wherein the welding positioner 1 It is located at one end of the triple tube of the heat collecting tube, and the jaws of the welding positioner 1 are in close contact with the surface of the inner tube at the end of the triple tube of the heat collecting tube, and the bottom of the welding positioner is fixed on the horizontal ground with anchor bolts; the several An adjustable lifting roller table 2 is installed on the same axis on the same horizontal plane as the welding positioner 1, and a distance is provided between two adjacent adjustable lifting roller tables 2, and each adjusta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com