Concrete spreader

A distributing machine and concrete technology, which is applied to the processing of building materials, construction, building construction, etc., can solve the problems of low automation, high labor intensity, and waste of working time, so as to achieve low labor intensity for operators and reduce labor intensity , Easy and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

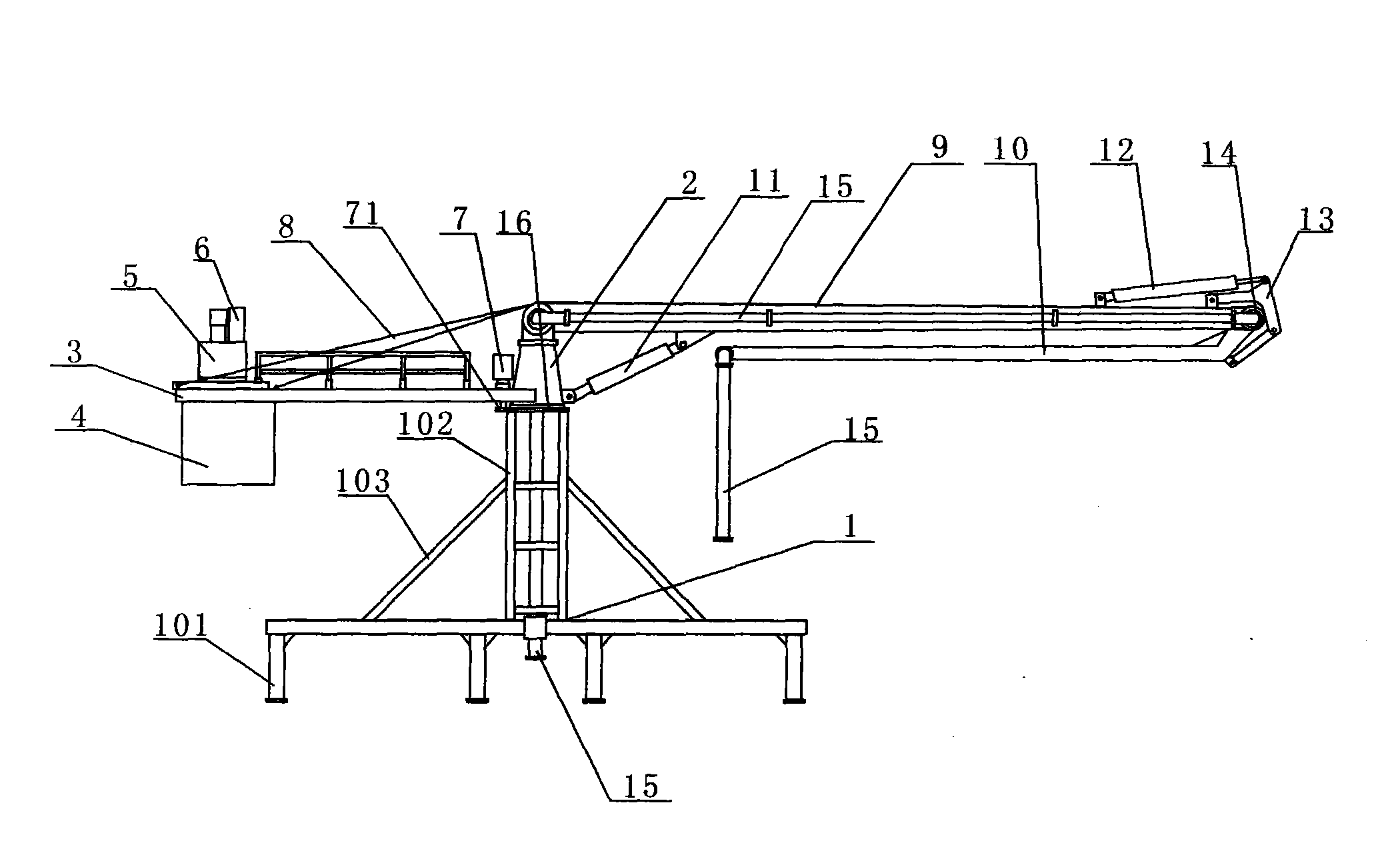

[0012] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0013] figure 1 Shown in, the present invention mainly consists of frame (1), conical tower (2), counterweight frame (3), counterweight box (4), hydraulic station (5), electric control box (6), speed reducer ( 7), boom support (8), boom (9), forearm (10), boom oil cylinder (11), forearm oil cylinder (12), connecting rod payment (13), rolling bearing (14) and cloth Composed of tubes (15), it is characterized in that: the conical tower (2) is fixed on the frame (1) through bearing activities, the counterweight frame (3) is fixed on the conical tower (2), and the counterweight box (4) is fixed At the lower end of the counterweight frame (3), the hydraulic station (5) is fixed on the upper end of the counterweight frame (3), the electric control box (6) is fixed on the hydraulic station (5), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com