Electromagnetic type metering valve

A metering valve, electromagnetic technology, applied in the field of electromagnetically controlled liquid metering valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

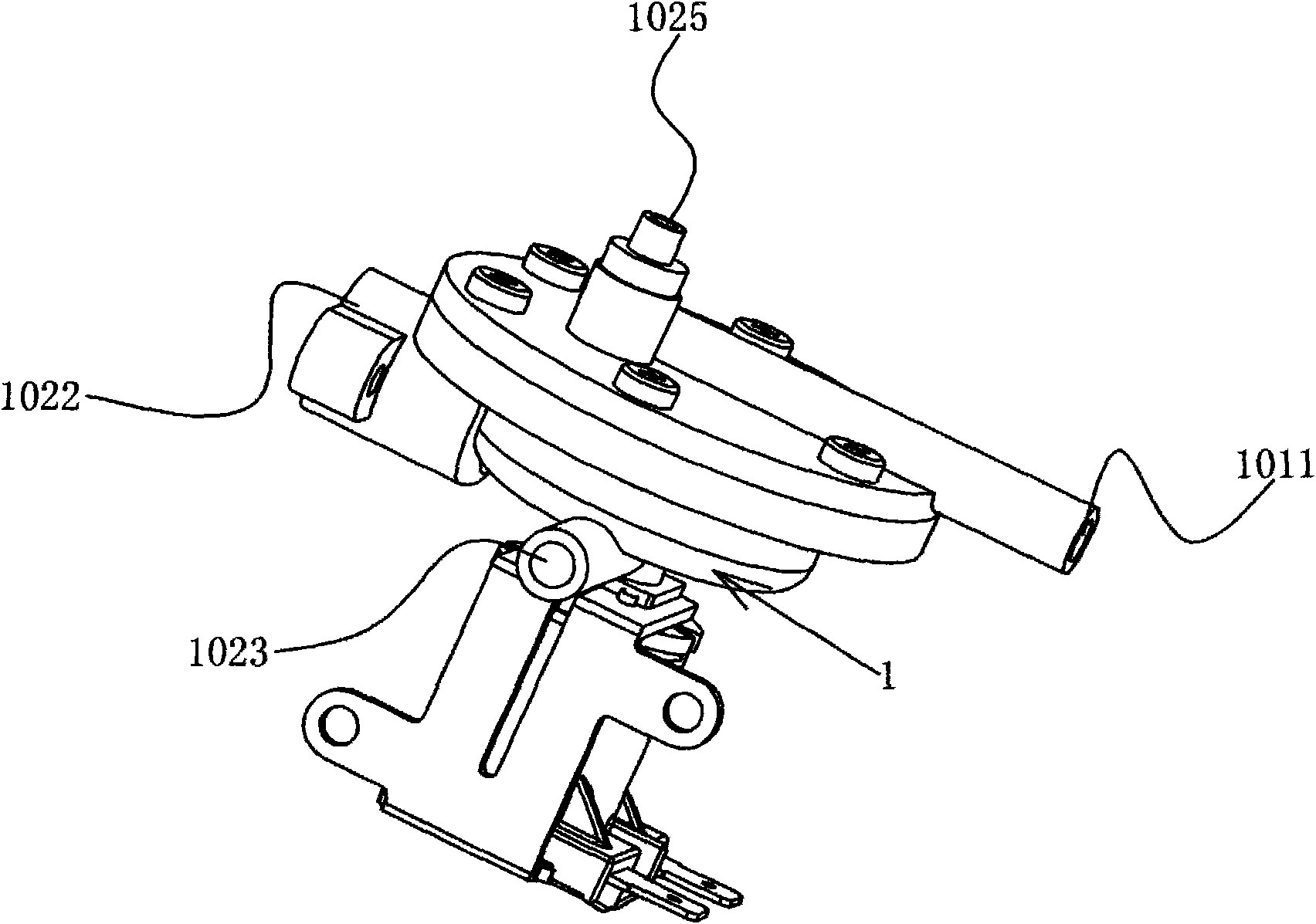

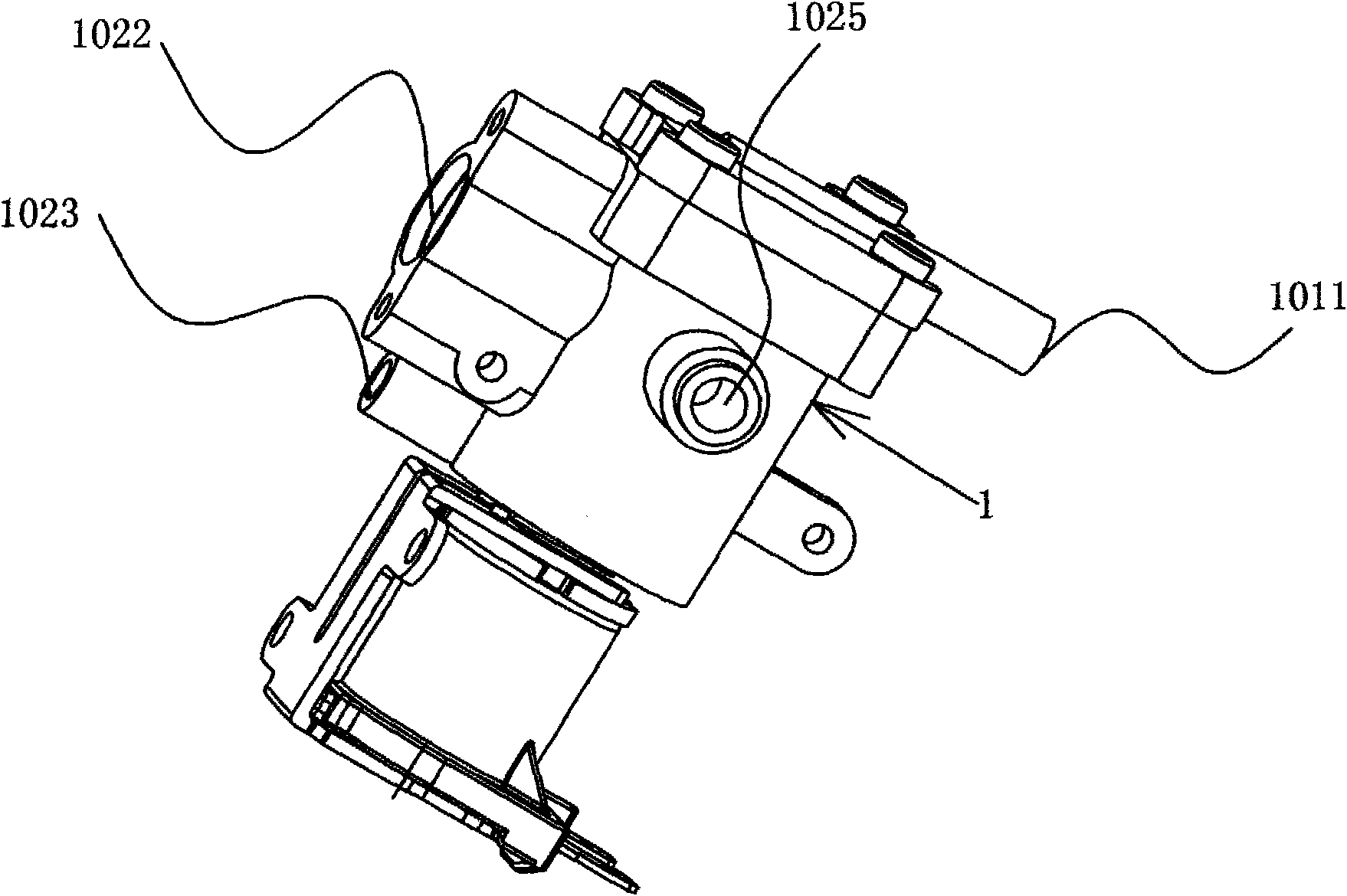

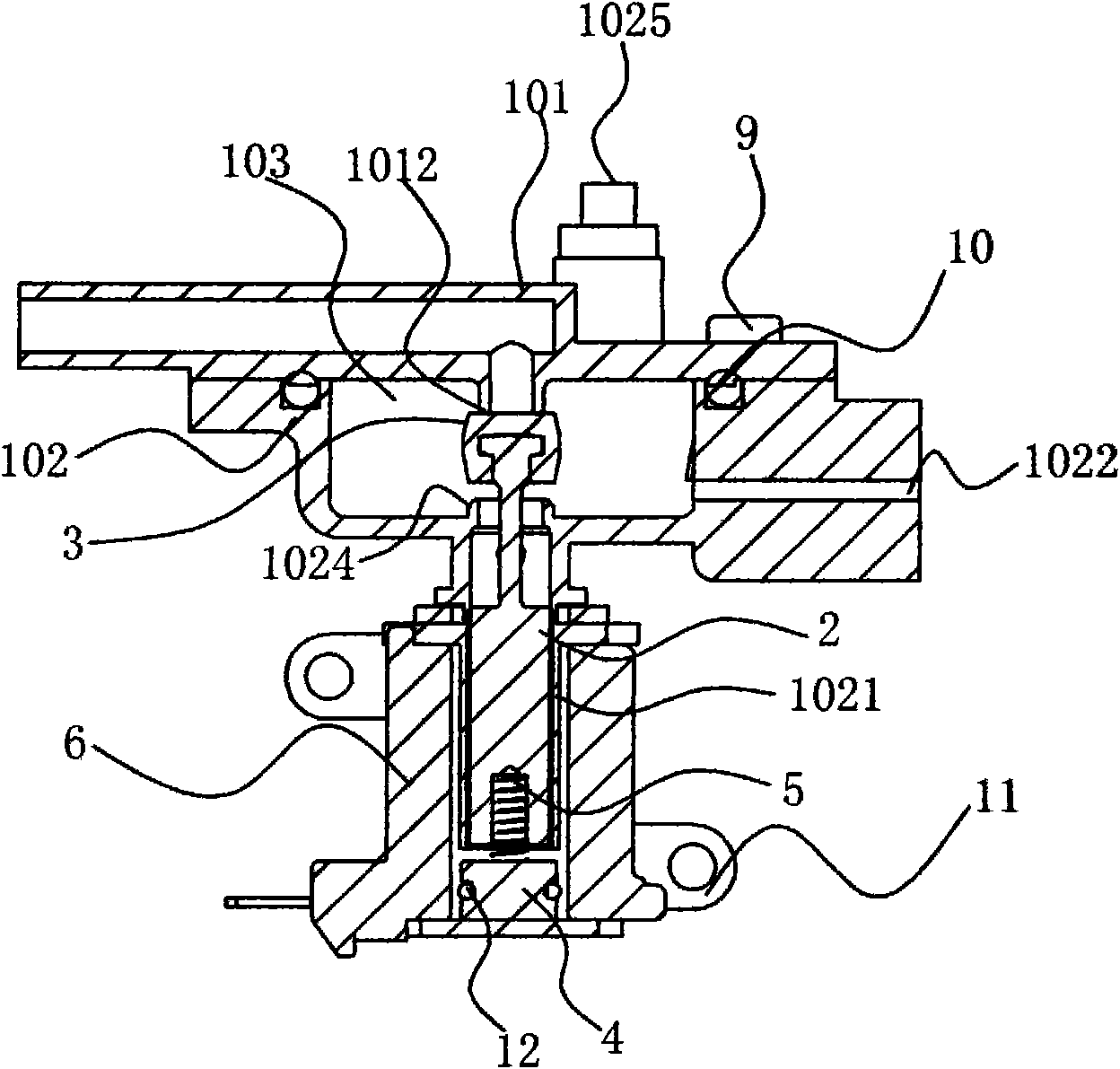

[0046] The electromagnetic metering valve of the present embodiment, such as Figure 1a , Figure 1b , Figure 2a , Figure 2b , Figure 3a , Figure 3b As shown, valve body A101 and valve body B102 formed by resin form valve body 1 with metering chamber 103. Valve body A101 and valve body B102 can be connected and sealed by screws 9 and O-rings 10, or by ultrasonic welding. The method of directly connecting together; adjusting the volume inside the valve body can adjust the capacity of each metering; the valve body B102 has a conduit 1021 connected with the metering chamber 103, the inlet A1011 is formed on the valve body A101, and the valve seat A1012 is formed on the A valve seat B1024, a conduit 1021 and an exhaust port 1025 are formed on the valve body A101 and the valve body B102, and the exhaust port 1025 communicates with the metering chamber 103;

[0047] The inflow port B1022 is directly formed on the valve body B, and the diameter of the inflow port B communicat...

Embodiment 2

[0056] The electromagnetic metering valve of this embodiment is based on the first embodiment, a check valve 7 is set in the inlet B1022 and a ball valve 8 is set at the exhaust port 1025, as Figure 4a , Figure 4b , Figure 5a , Figure 5b , Figure 6a , Figure 6b As shown, the one-way valve has a spool 701 and a one-way valve body 703. One end of the spool runs through the through-hole of the retaining wall in the inlet 1022. A spring 702 is arranged between the retaining wall and the spool 701. The spool is driven by the action of the spring. The other end of the spool is pressed on the sealing surface of the one-way valve body;

[0057] The end portion of the valve core can also be sealed with the valve body by setting an O-ring 704, or can be directly sealed with plastic contact.

[0058] Inflow port B1022 is due to the effect of one-way valve 7 during metering action like this, and the liquid in the metering chamber 103 just can not flow through inflow port B and ...

Embodiment 3

[0061] The electromagnetic metering valve of the present embodiment, such as Figure 7a , Figure 7b , Figure 8a , Figure 8b Show, be on the basis of embodiment one, two, add tee pipe 17 on inlet B, then change fixed iron core 4 into the elongated fixed iron core 18 that has through hole; After electromagnetic coil 6 is energized , the movable iron core 2 is attracted by the magnetic force to move toward the direction of the extended fixed iron core 18, and the piston cap 3 is placed on the valve seat B1024. At this time, the controller opens the external solenoid valve connected to the three-way nozzle A1701, and a part of the tap water The water pressure is applied to the inflow port B1022 through the three-way nozzle C1703, and then enters the metering chamber 103 to mix with the detergent in the metering chamber, and the mixed liquid is squeezed out through the exhaust port 1025 and the outflow port 1023, and flows into the washing machine tank h Inside; the other par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com