Trough-type vacuum tube heat collecting device of condenser heat tube

A technology of heat collecting device and vacuum tube, which is applied in the field of solar energy concentration, can solve the problems of unstable performance of selective coatings, etc., and achieve the effects of easy acquisition, cost reduction, and increase of heat absorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

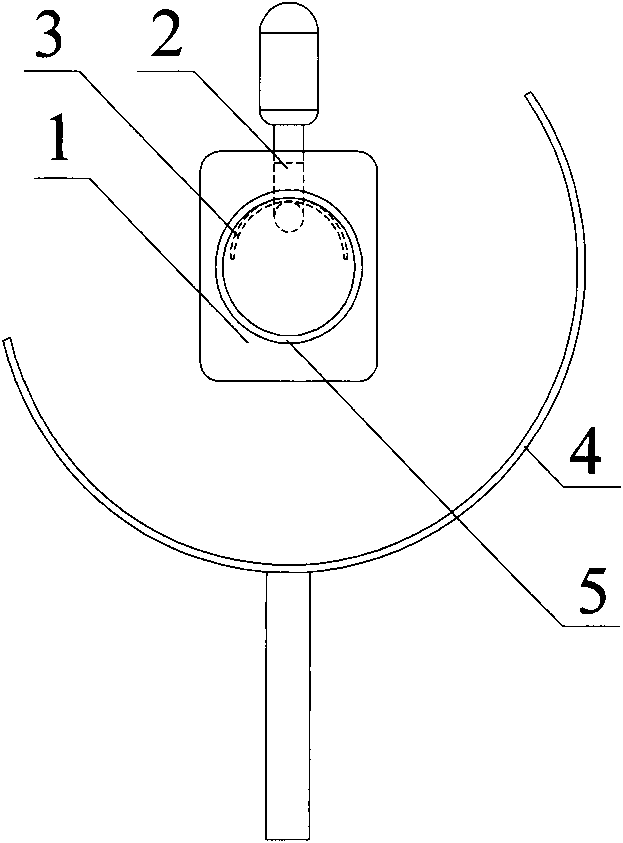

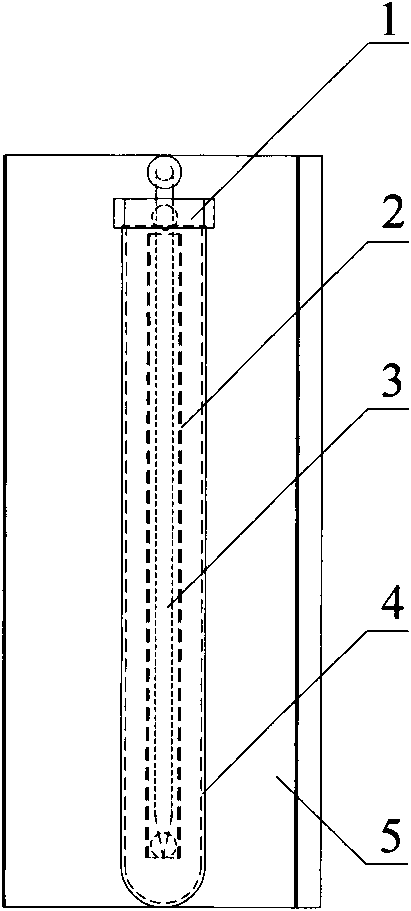

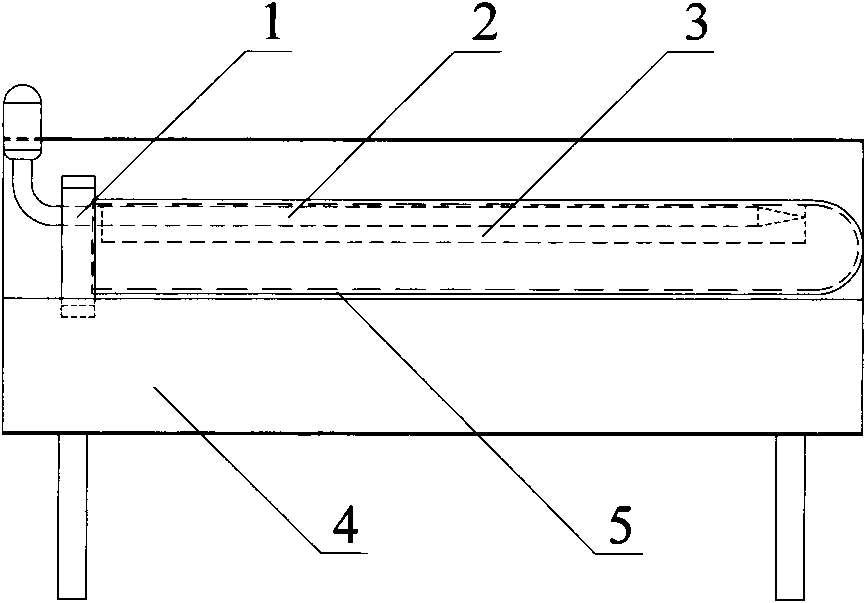

[0017] The trough-type concentrating heat pipe vacuum tube heat collecting device of the present invention includes a heat collector and a trough-type concentrator 4, wherein the heat collector is composed of a glass vacuum tube 5 and a copper heat pipe 2 positioned in the glass vacuum tube 5, and the heat collector is connected with the heat collector. The trough concentrator 4 is placed in parallel and located on the focal line of the trough concentrator 4 . The copper heat pipe 2 has curved fins 3, which are welded together, and the other side of the fins 3 is closely attached to the inner wall of the glass vacuum tube 5, and the heat-absorbing surface of the inner glass of the glass vacuum tube 5 is coated with There is a selective coating with high absorption rate and low emissivity, and the ends of the two tubes are closed, and the condensing end of the heat pipe is exposed outside the vacuum tube and extends into the heat-absorbing working fluid. One end of the glass va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com