Method for extracting feature information of weak faults of low-speed heavy-duty equipment

A fault feature, low-speed and heavy-load technology, applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as low impact response frequency, failure to diagnose faults, submersion, etc., and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

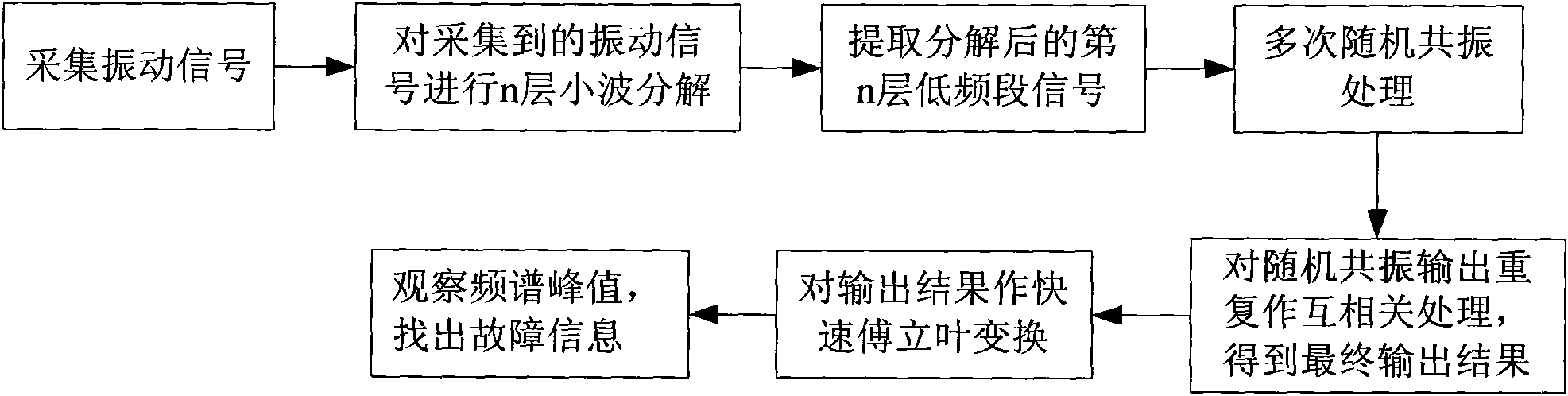

[0034] The embodiment of the method of the present invention takes the common bar roughing mill reduction box in iron and steel production enterprises as an example, and the present invention will be further described below in conjunction with the accompanying drawings:

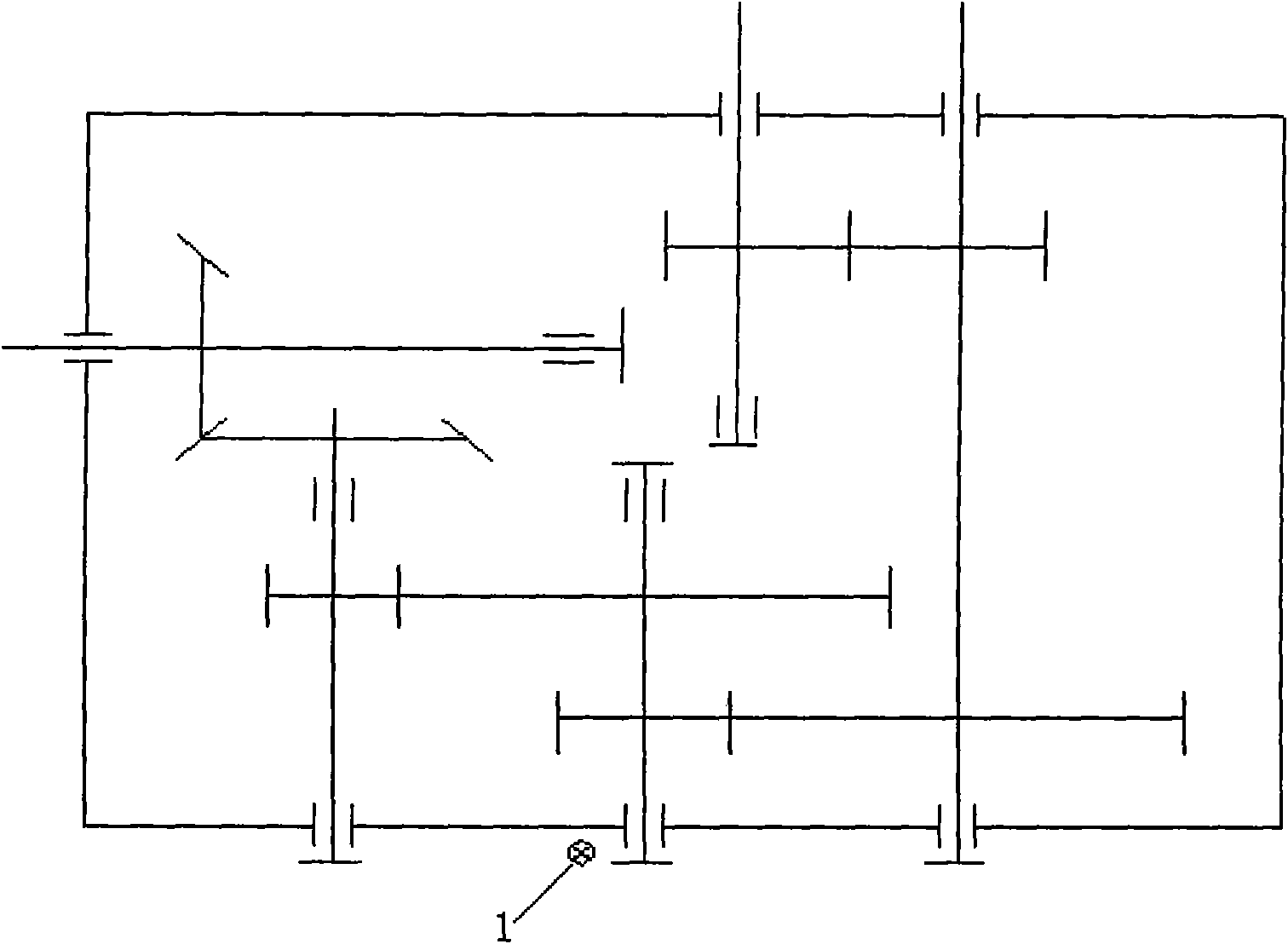

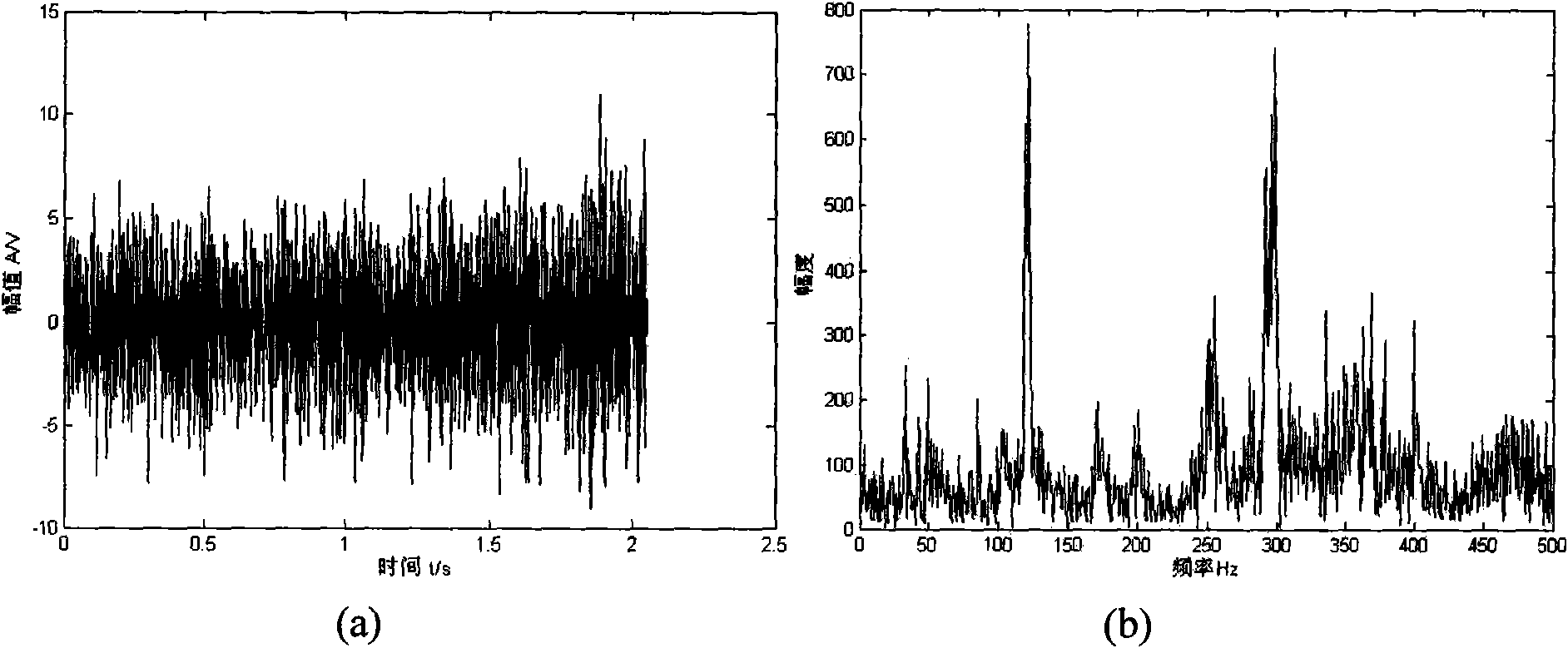

[0035] 1) Install the vibration acceleration sensor on the bearing seat of the reduction box of the rolling mill, and collect the vibration signal of the rolling mill in the working state through the vibration data acquisition instrument connected with the vibration acceleration sensor. The transmission diagram of the reduction box of the rolling mill is as follows figure 2 as shown, figure 2 The number 1 in the figure indicates the installation position of the vibration acceleration sensor; image 3 (a), image 3 (b) shows the waveform diagram and spectrum diagram of the original vibration signal collected from the reduction box of the rolling mill respectively.

[0036] 2) Carry out wavelet decompositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com