Method for detecting heat resistance of electric wire and detection device thereof

A technology of wire and cable and detection method, which is applied in the field of detection of wire and cable performance, can solve problems affecting product reputation, etc., and achieve the effects of simple structure, accurate detection data, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

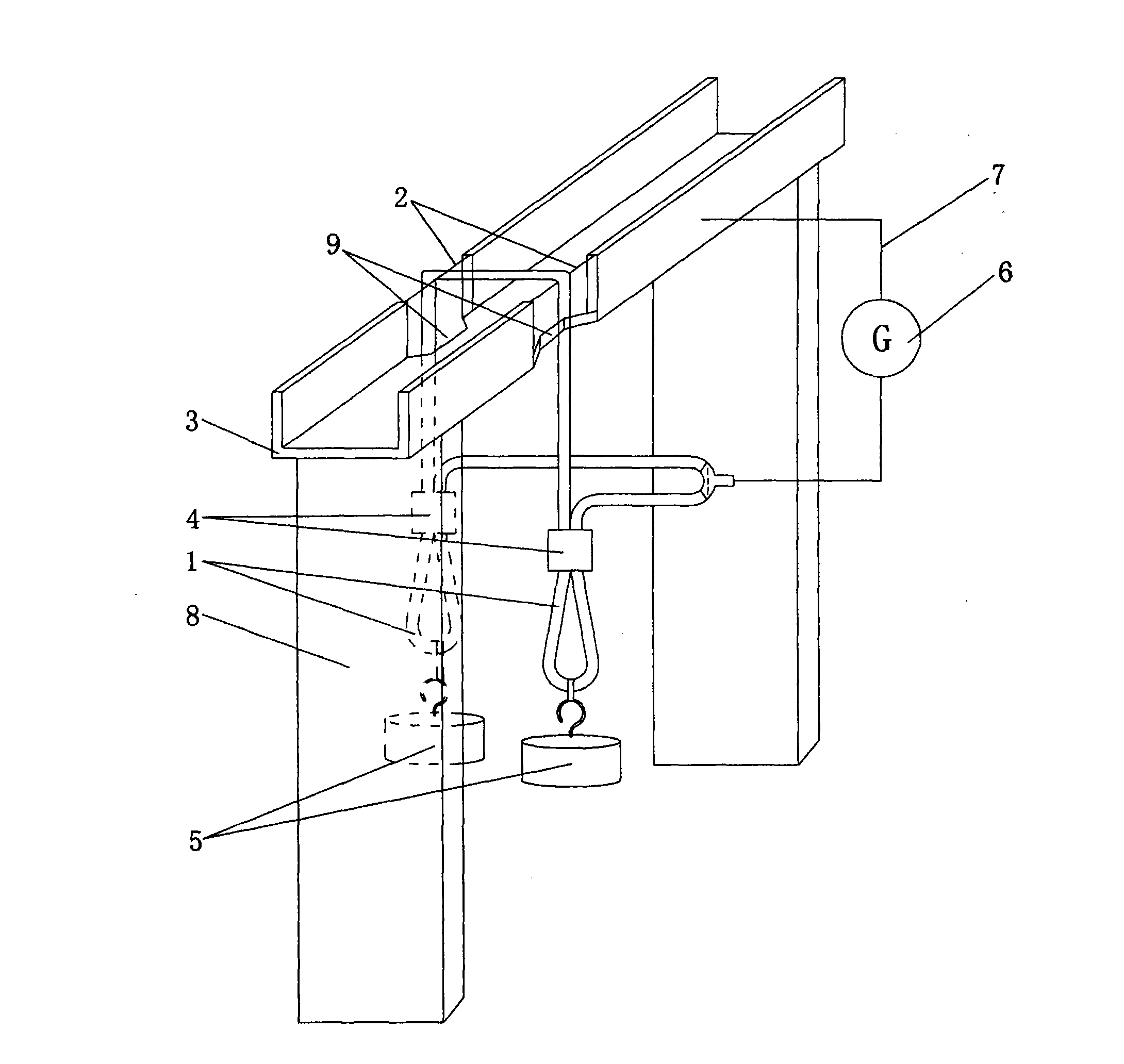

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] refer to figure 1 , the wire and cable heat resistance detection method comprises the following steps:

[0015] (1) Take a finished wire and cable sample that is at least 1m long, and attach a weight to each end of the sample as a load. The weight of the load is about 2mm 2 Or thinner wires can be selected in the range of 100g-500g, for cross-section greater than 2mm 2 The load of the wire can be selected between 500g-1000g. The two ends of the sample should be stripped of a section of insulation, and then the conductors at both ends should be connected together (the wire is connected with the core, and the cable is connected with the shield), and then through the lead wire and the universal One end of the meter is connected.

[0016] (2) Hang the central part of the sample on the middle position of a U-shaped metal groove with the opening facing upwards. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com