Large-current electric rotary connector

A rotary connector, high-current technology, applied in the direction of rotary current collectors, connections, current collectors, etc., can solve the problem of large heat generation of brushes and electric slip rings, improve transmission performance and use performance, and ensure current carrying. Ability, ease of positioning and effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

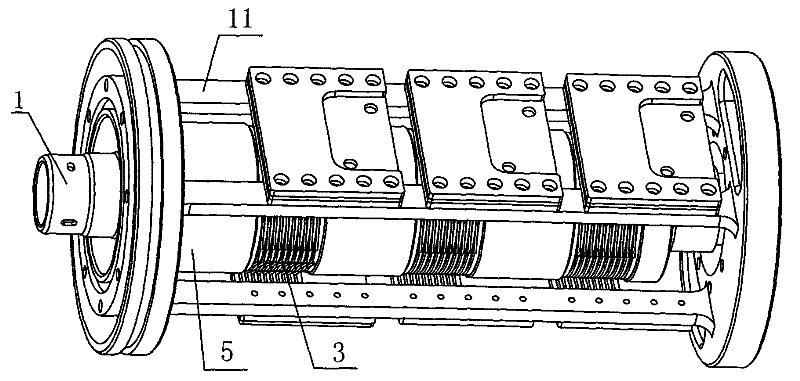

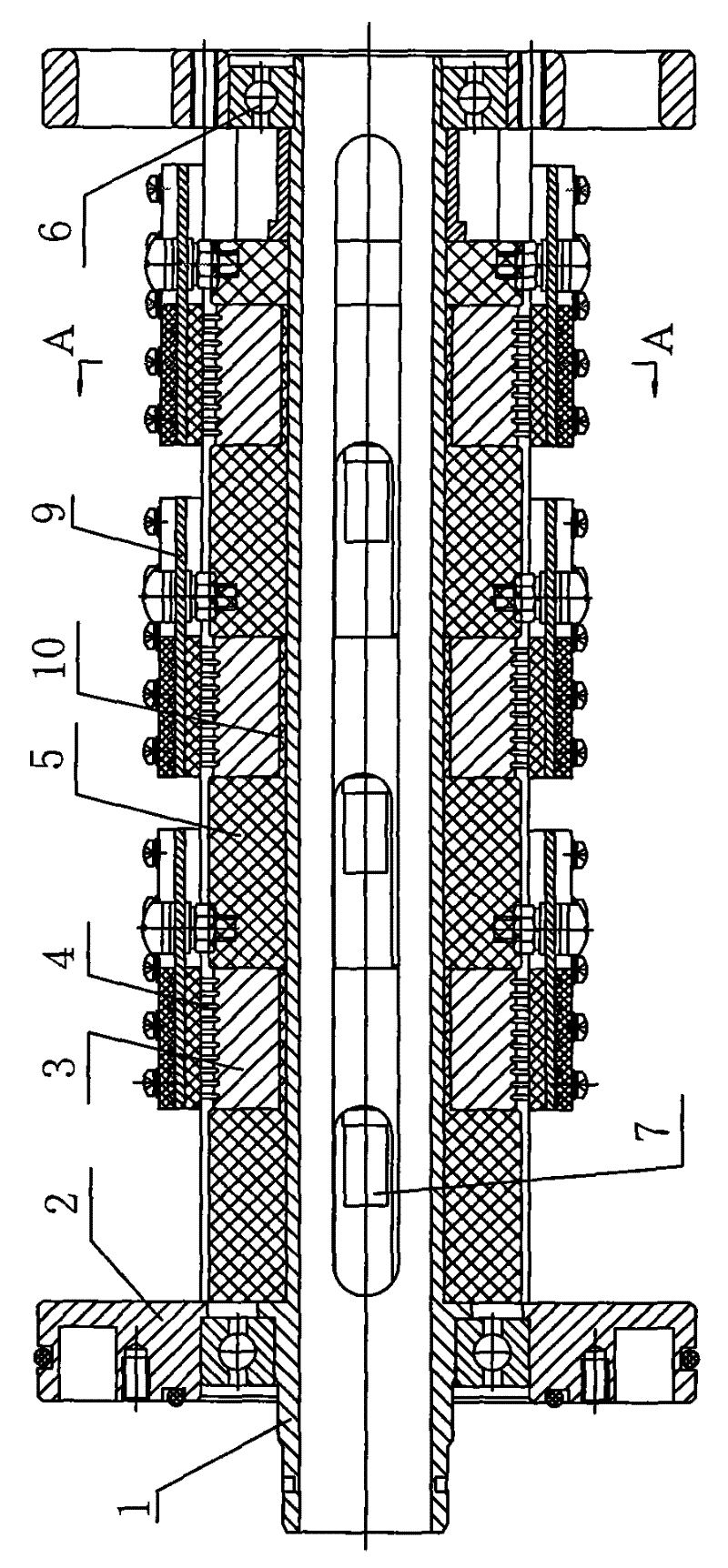

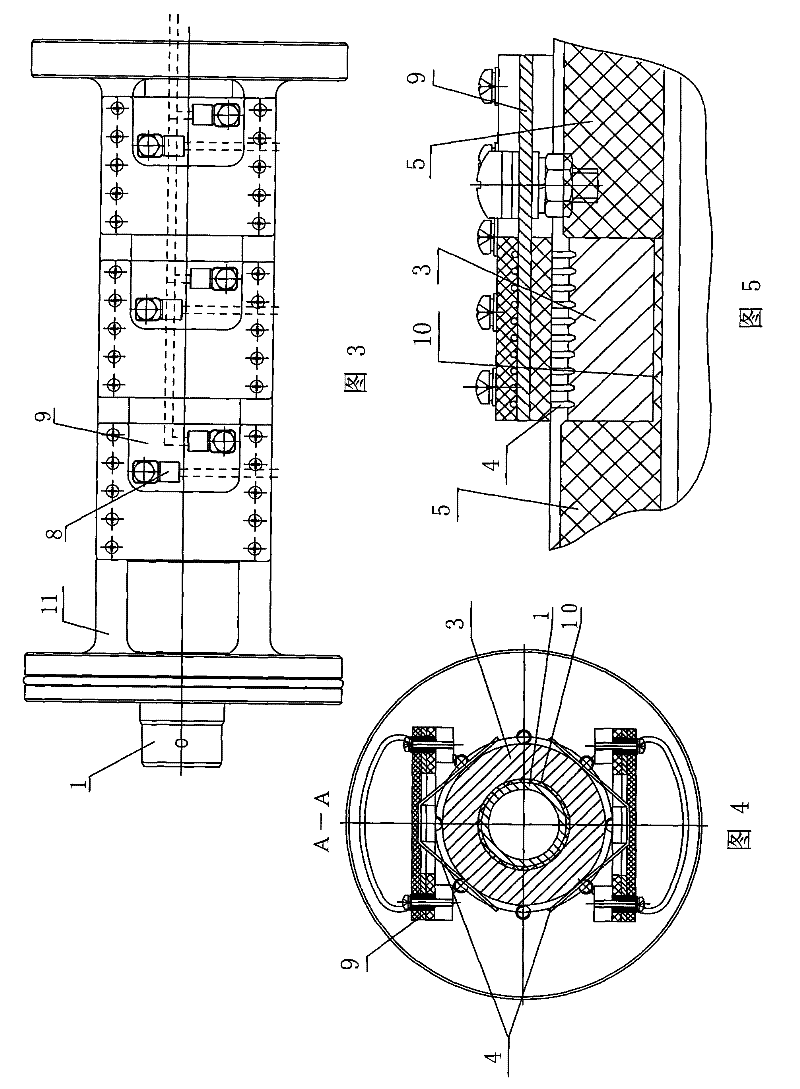

[0017] Figure 1-5 The high-current electrical rotary connector shown includes a hollow slip ring shaft 1, a first cable joint 7 is provided inside the slip ring shaft, and support frames 2 are set on both ends of the slip ring shaft, and the two support frames pass through the bridging beam 11 is connected as a whole, and a bearing support 6 is installed between the slip ring shaft 1 and the support frame 2; the part of the slip ring shaft between the two bearing supports is alternately sleeved with an insulator 5 and an electric slip ring 3, and each electric slip ring 3 An insulating sleeve 10 is provided between the inner hole of the slip ring and the shaft of the slip ring. Each insulating sleeve 10 is integrally formed with the insulator 5 located on the same side of the corresponding electric slip ring. Of course, it can also be separated. Each electric slip ring 3 The insulator 5 and the insulating sleeve 10 are insulated and matched with the slip ring shaft 1, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com