Garlic harvester

A harvester and garlic technology, which is applied in the direction of digging harvesters, harvesters, excavators, etc., can solve the problems of garlic with soil, imperfect supporting technology, and inability to accurately grasp the working depth of the shovel, and achieve ideal results. Measures Powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

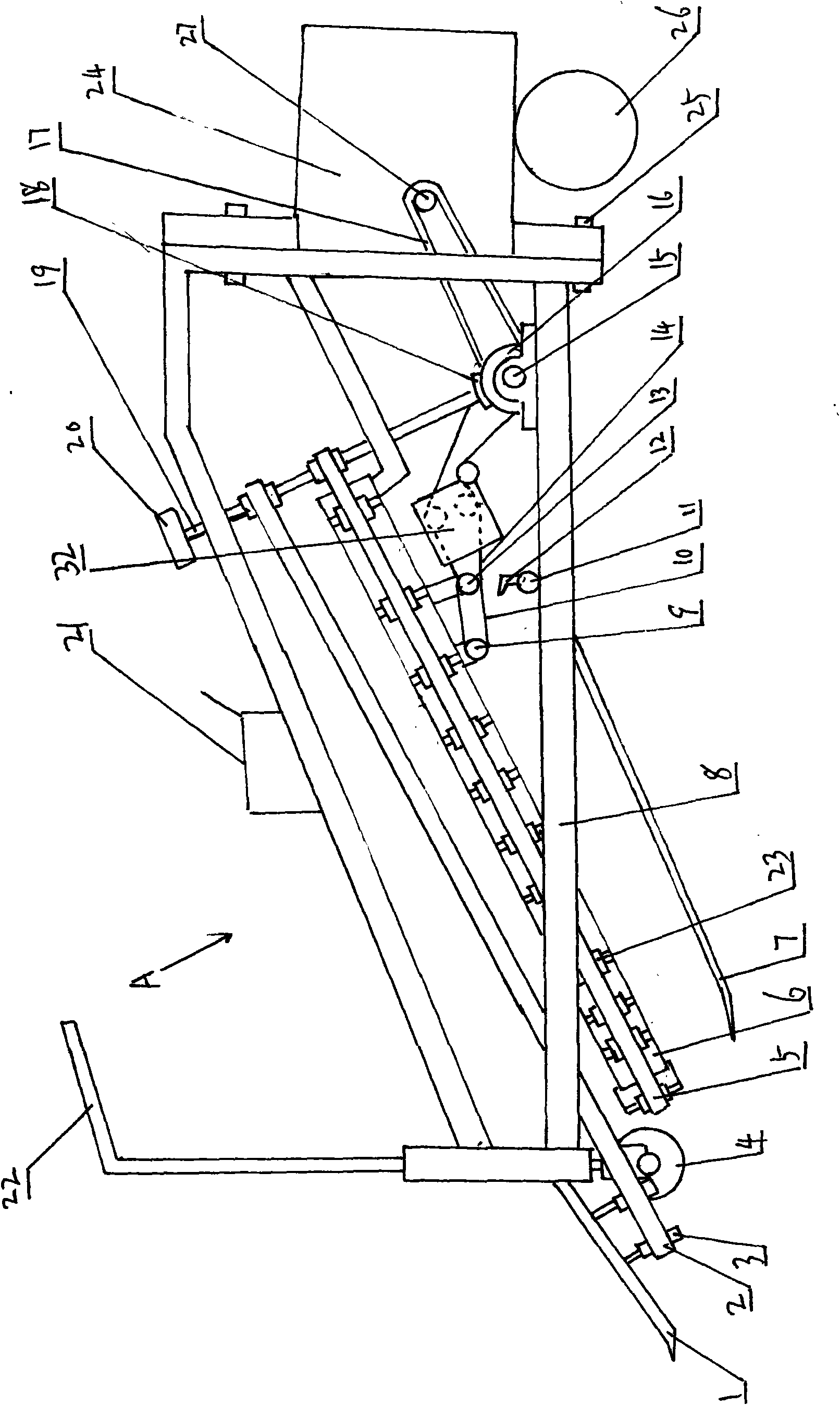

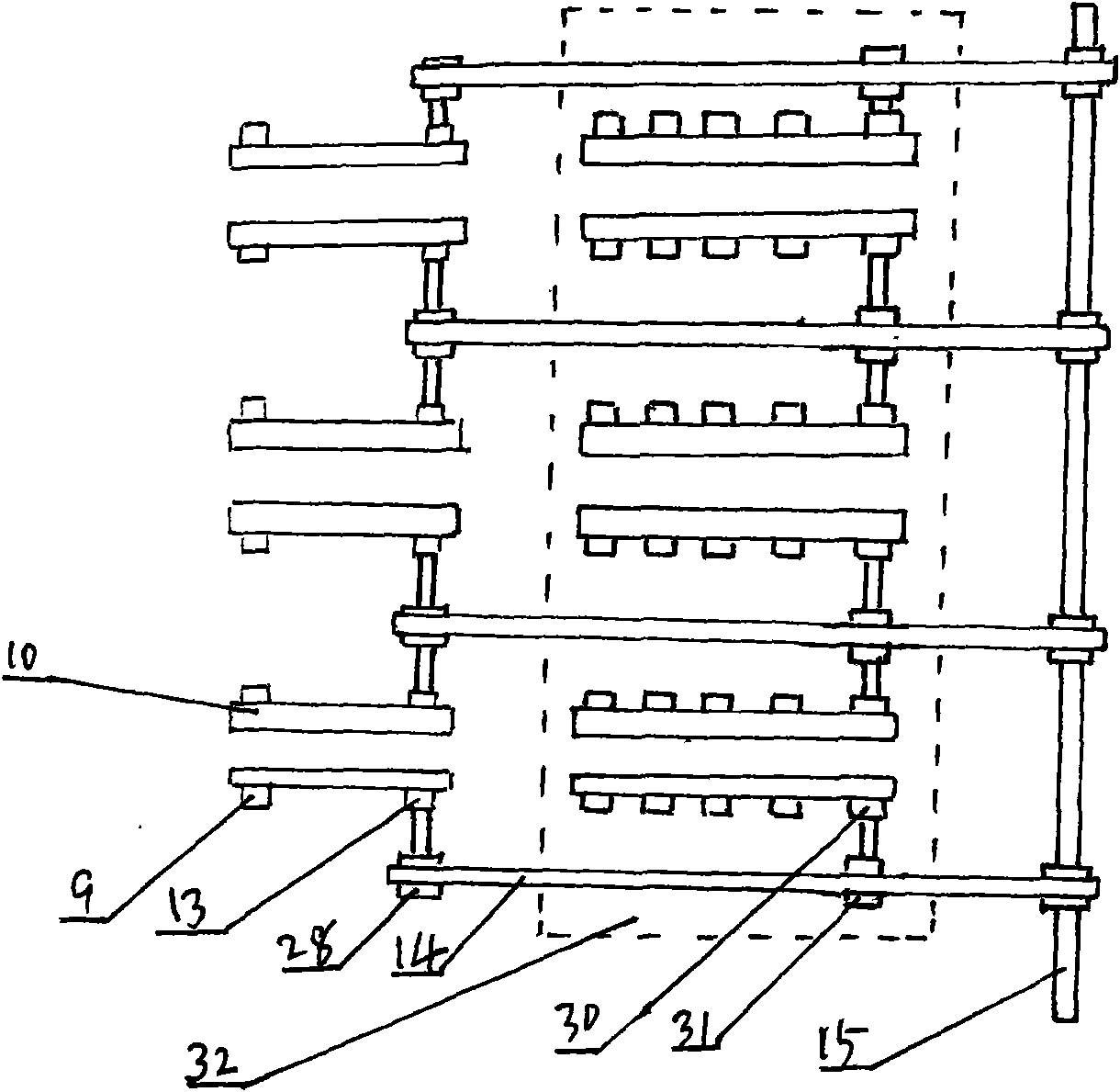

[0021] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the garlic harvester of the present invention is composed of two parts, the supporting power machinery 24 and the garlic harvesting special machinery arranged before the supporting power machinery, the two are connected by screws 25, and the front wheel 4 is set on the garlic harvesting machine in the working state. The front end of the harvesting special machine is fixed on the frame 8, and the rear wheel 26 in the working state is the ground power wheel of the supporting power machine 24. The working shovel 7 is also arranged on the frame 8. Between the front wheel 4 and the working state walking rear wheel 26, the working state walking front wheel 4 and the working state walking rear wheel 26 are set between the rows of the operation shovel 7 operation garlic rows, so as to prevent the working state walking rear wheel from crushing the garlic. The specific operation should be based on the actual planting ha...

Embodiment 2

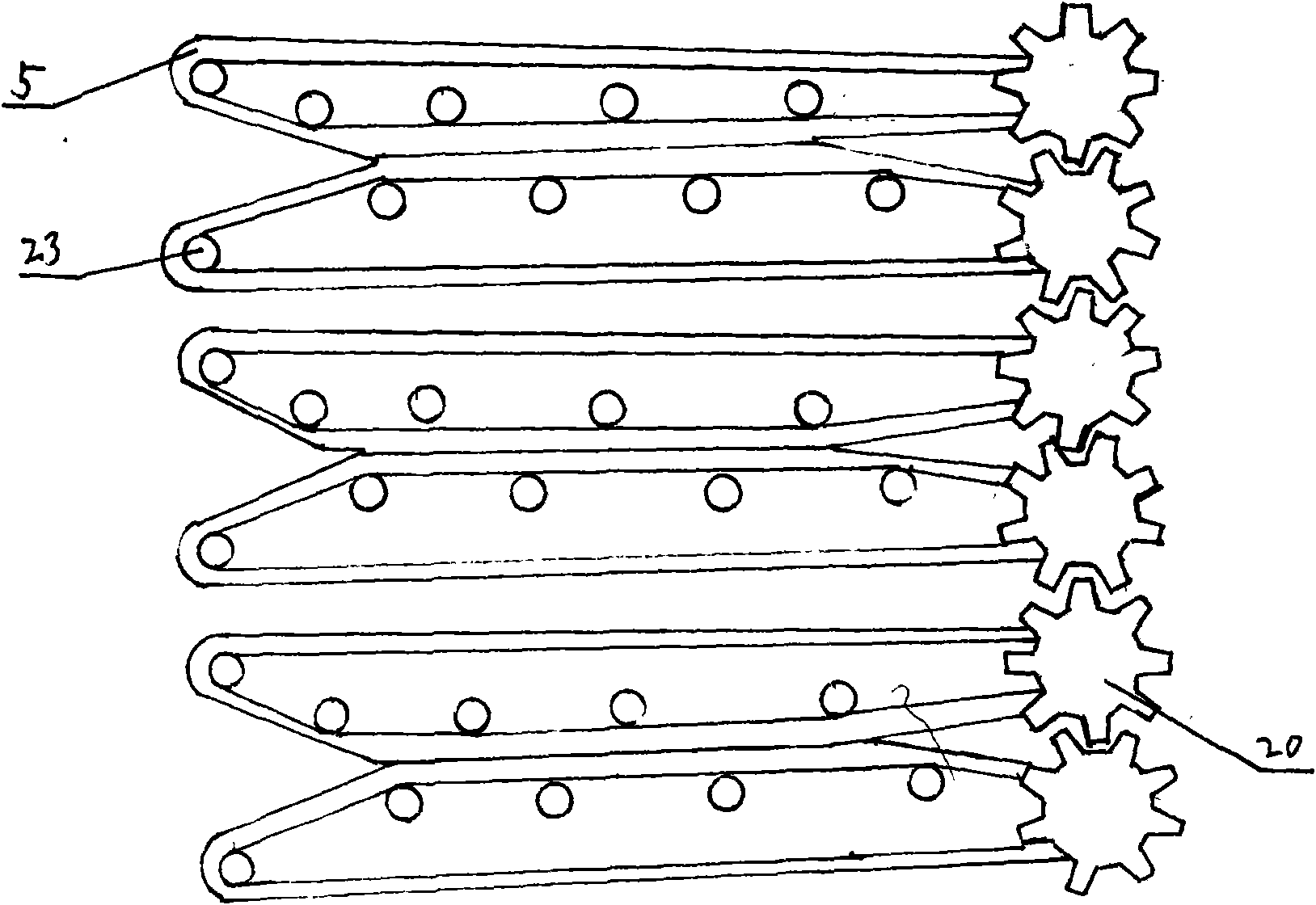

[0027] Embodiment 2, this embodiment is mostly the same as Embodiment 1, except that the garlic seedling clamping conveyor belt and the transmission device connected to the clamping conveyor belt are different, such as Figure 4 , Figure 5 In the garlic harvester of the present invention, the pick-up device adopts a flat-belt type clamping and pulling transport pick-up device, which is characterized in that a horizontal horizontal power transmission shaft B33 is arranged at an appropriate position, and the rear end support wheel of the clamping and pulling conveyor belt 36 is directly arranged on the On the horizontal horizontal power transmission shaft B33, through a certain transmission device, the horizontal horizontal power transmission shaft B33 is connected to the main power wheel 35 on the power machine by a chain 34, so that after the power machine starts, the main power wheel 35 on the power machine can pass The chain 34 drives the horizontal horizontal power transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com