Resistance furnace

A technology of resistance furnace and furnace chamber, which is applied in electric furnace heating, furnace cooling, etc., and can solve the problem of difficult temperature distribution adjustment due to temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

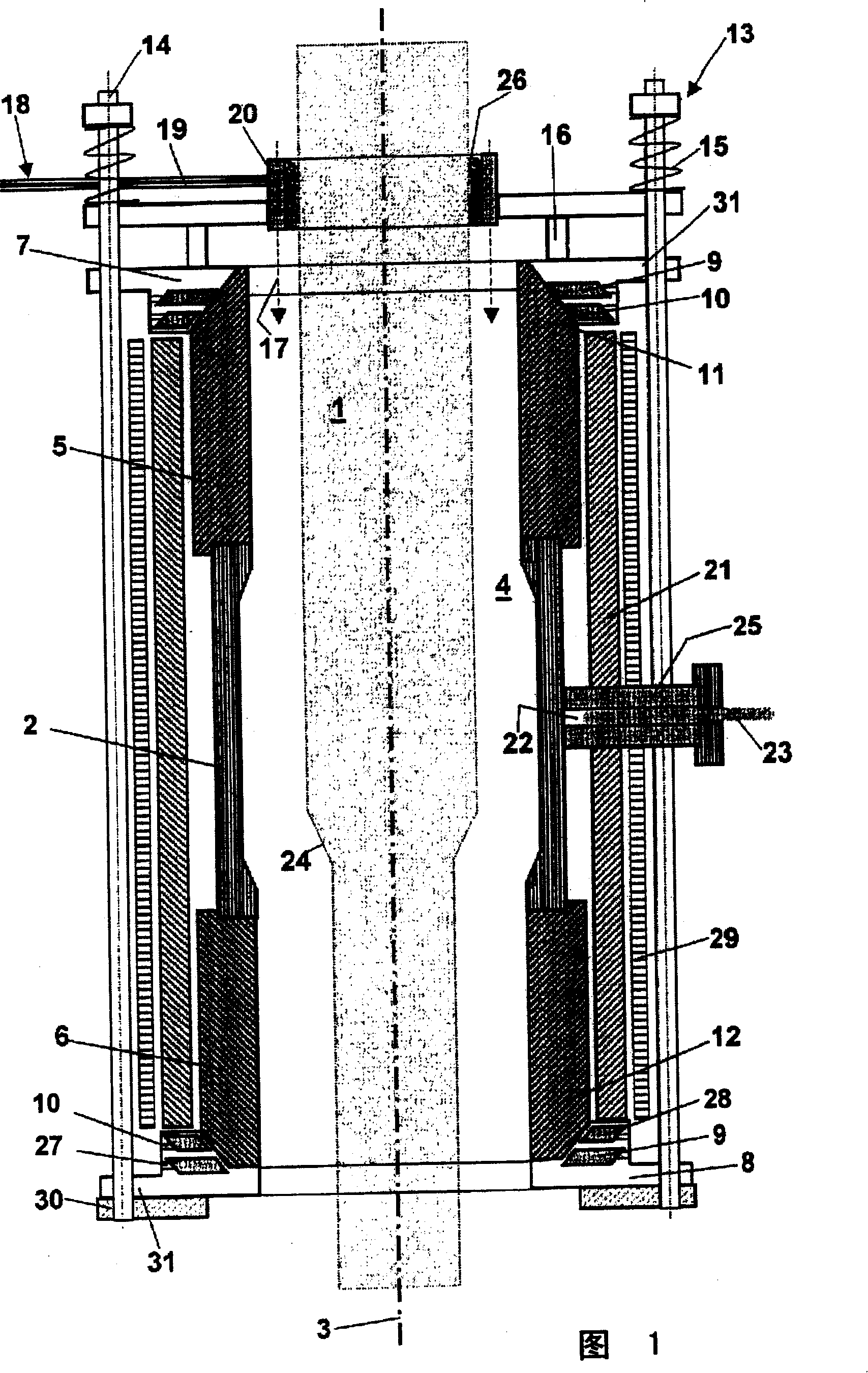

[0038] The electric resistance furnace shown in FIG. 1 of the present invention is used for heating and stretching a quartz glass cylinder 1 . This resistance furnace is a high-performance resistance furnace with a maximum heating capacity of 700kW. The electric resistance furnace comprises a graphite heating tube 2 with a vertically oriented longitudinal axis 3 , which encloses a heating chamber 4 .

[0039] The contact tubes 5, 6 are located at the front of the heating tube 2 on both sides. The contact tubes 5 , 6 are also made of graphite and have a greater wall thickness than the heating tube 2 .

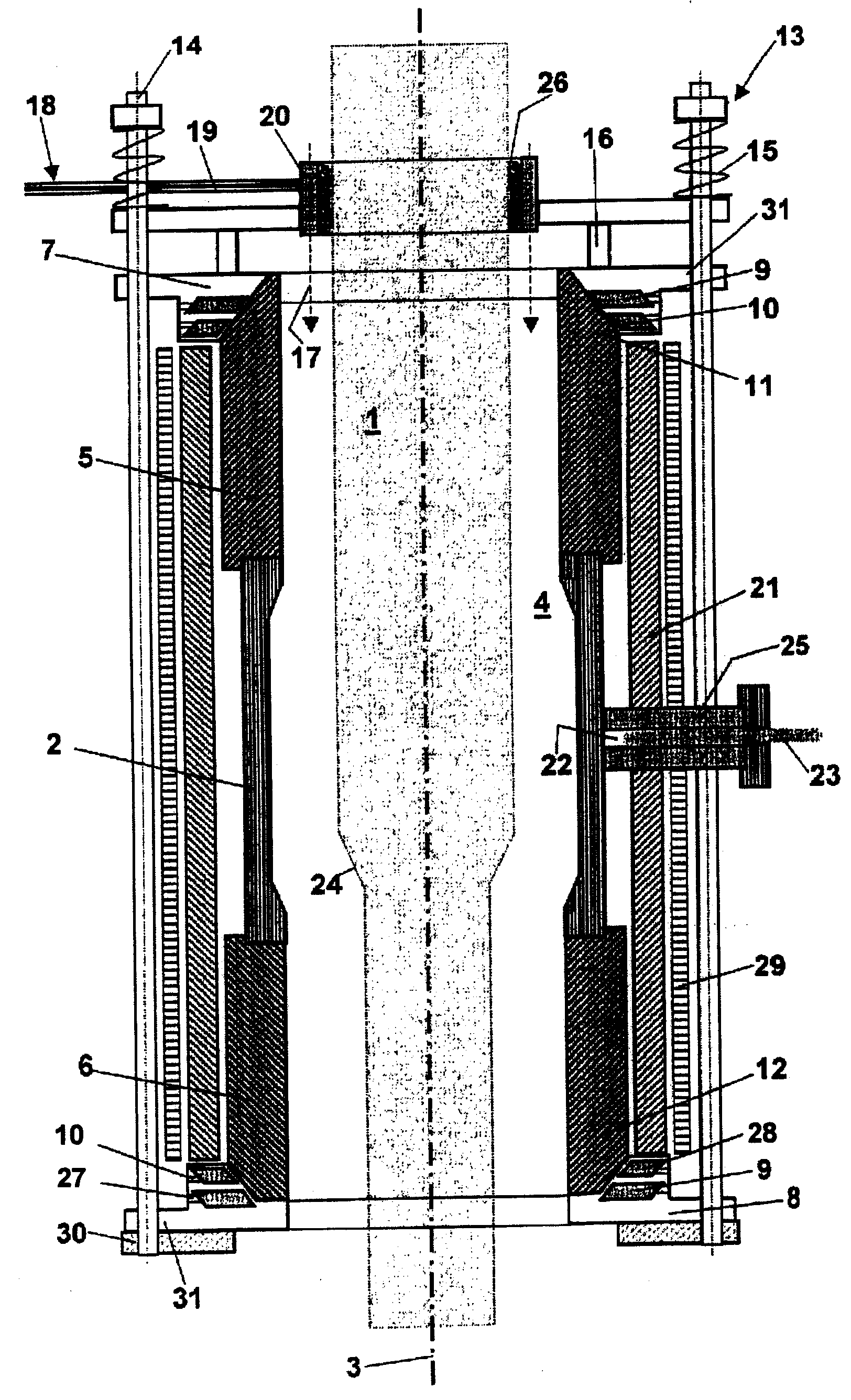

[0040] The current is introduced into the heating tube 2 through annular collars 7, 8, the annular collars are made of copper alloy CuCrZr, the upper annular collar 7 is located on the upper side 11 of the upper contact tube 5 and the lower annular collar 8 is located on the lower contact tube 6 underside 12 . The ring collars 7, 8 comprise outwardly protruding flanges 31 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com