Anticorrosive method of inner cavity of sealable metal component with multi-cavity structure

A metal component, multi-cavity technology, applied in the field of aviation chemical industry, can solve problems such as loss of manpower, material resources, financial resources, corrosion of parts, existence of edges and corners, etc., to achieve the effect of reducing costs, reliable measures, and inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

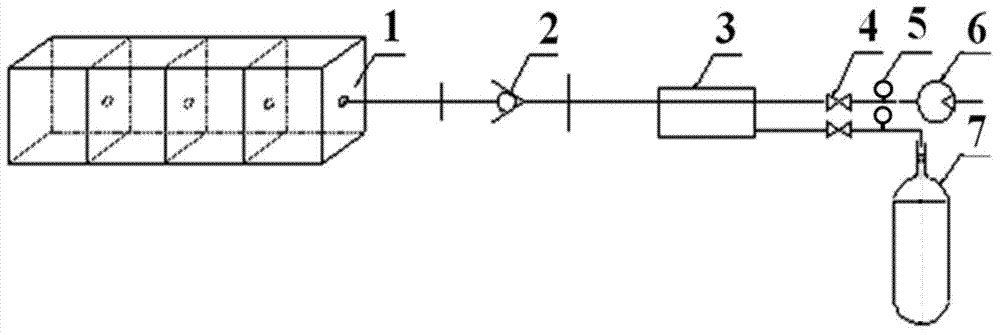

[0043] This embodiment provides an anti-corrosion method capable of sealing the inner cavity of a metal member with a multi-cavity structure. The main process flow of the anti-corrosion method is as follows: figure 2 As shown, it specifically includes the following steps:

[0044] Clean the inner cavity of the sealable multi-cavity structure metal member 1 with absolute ethanol;

[0045] Dry the inner cavity naturally;

[0046] The tail section of the cavity of the sealable multi-cavity structural metal member 1 uses a stop valve 4 to block the pores of the sealable multi-cavity structural metal member 1;

[0047] The three-way joint 3 is adopted to communicate with the air hole of the sealable multi-cavity structure metal member 1 cavity, the vacuum pump 6, and the gas bottle 7 respectively, and a pressure gauge 5 is installed at the ends of the vacuum pump 6 and the gas bottle 7, and the three-way joint 3 is connected to the gas bottle. A one-way valve 2 is connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com