A thermal spray sealing agent suitable for high temperature and high pressure downhole environment and its application method

A technology of high temperature, high pressure and pore sealing agent, applied in coating, melt spraying, anti-corrosion coating, etc., can solve the problems of unsuitable bimetal composite spray coating, affecting performance, etc., to enhance adhesion and anti-corrosion performance, reduce porosity rate, the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: In terms of mass fraction, mix 63% polysilsesquioxane, 8% ceramic powder with a particle size of 30nm, and 30% silica hydrosol with a particle size of 10nm, and fully stir to obtain a sealing agent, wherein , The preparation method of polysilsesquioxane is: mix 3-glycidyl etheroxypropyltrimethoxysilane KH560 and tetraethyl orthosilicate TEOS at a mass ratio of 78:22, add deionized water, use HCl as a catalyst, where H 2 The molar ratio of O, HCl and KH560 is 2:0.0005:1, fully stirred and reacted at 80°C for 50 minutes to form polysilsesquioxane;

[0031] Step 2: Apply the sealing agent evenly on the surface of the thermal spray coating with an atomized spraying method. Dry at low temperature.

[0032] Experiment results and analyze the results.

Embodiment 2

[0034] Step 1: In terms of mass fraction, mix 70% polysilsesquioxane, 5% ceramic powder with a particle size of 20nm, and 26% silica hydrosol with a particle size of 20nm, and fully stir to obtain a sealing agent, wherein , The preparation method of polysilsesquioxane is: mix 3-glycidyl etheroxypropyltrimethoxysilane KH560 and tetraethyl orthosilicate TEOS at a mass ratio of 90:30, add deionized water, use HCl as a catalyst, where H 2 The molar ratio of O, HCl and KH560 is 3:0.0003:1, fully stirred and reacted at 70°C for 60 minutes to form polysilsesquioxane;

[0035]Step 2: Use atomized spraying method to evenly coat the sealing agent on the surface of the thermal spray coating with a coating thickness of 20 μm, so that the sealing agent can fully penetrate into the pores of the coating, and then apply the sealing agent at 60°C Dry at low temperature.

Embodiment 3

[0037] Step 1: In terms of mass fraction, mix 60% polysilsesquioxane, 10% ceramic powder with a particle size of 50nm and 25% silica hydrosol with a particle size of 15nm, and fully stir to obtain a sealing agent, wherein , The preparation method of polysilsesquioxane is: mix 3-glycidyl etheroxypropyltrimethoxysilane KH560 and ethyl orthosilicate TEOS at a mass ratio of 70:10, add deionized water, use HCl as a catalyst, where H 2 The molar ratio of O, HCl and KH560 is 1:0.001:1, fully stirred and reacted at a temperature of 90°C for 10 minutes to form polysilsesquioxane;

[0038] Step 2: Use atomized spraying method to evenly coat the sealing agent on the surface of the thermal spray coating with a coating thickness of 10 μm, so that the sealing agent can fully penetrate into the pores of the coating, and then apply the sealing agent at 80°C Dry at low temperature.

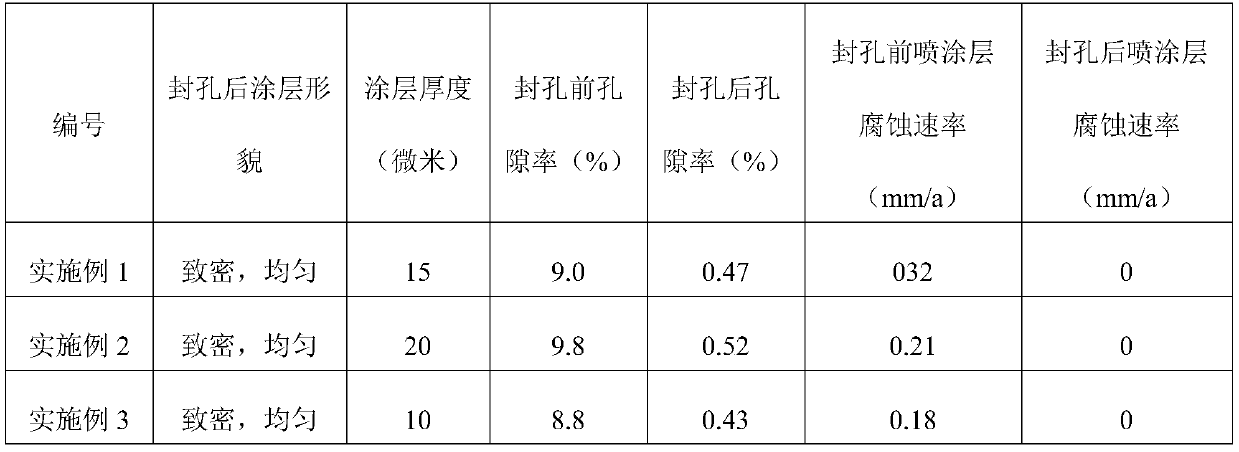

[0039] Table 1 shows the corrosion rate of the metal sprayed coating after the sealing treatment in Examples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com