An environmentally friendly corrosion-resistant single-layer pet color-coated steel plate

A corrosion-resistant and environmentally friendly technology, applied in coatings, layered products, anti-corrosion coatings, etc., can solve problems such as high production costs, non-scratch resistance, and easy crushing of PVC layers, so as to enhance corrosion resistance and improve Scratch resistance, good physical barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

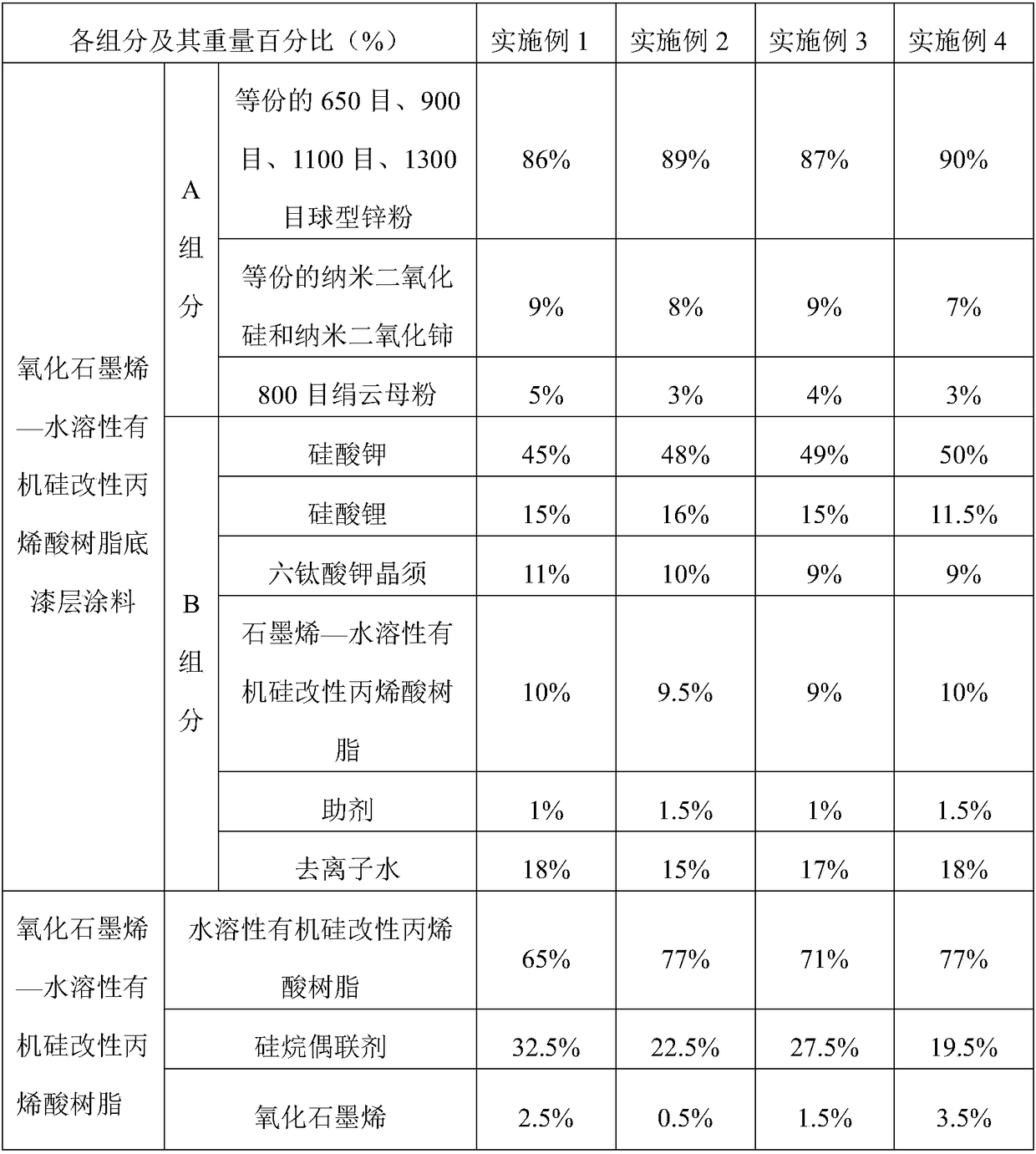

Embodiment 1~ Embodiment 4

[0043] Embodiment 1~Example 4 The preparation method of single-layer PET color coated steel plate is as follows:

[0044] Step 1: unwinding, cleaning and drying;

[0045] Step 2: passivate both sides of the steel plate substrate with a chromate chemical pretreatment solution with a concentration of 30 wt%, and dry to obtain a chemical coating;

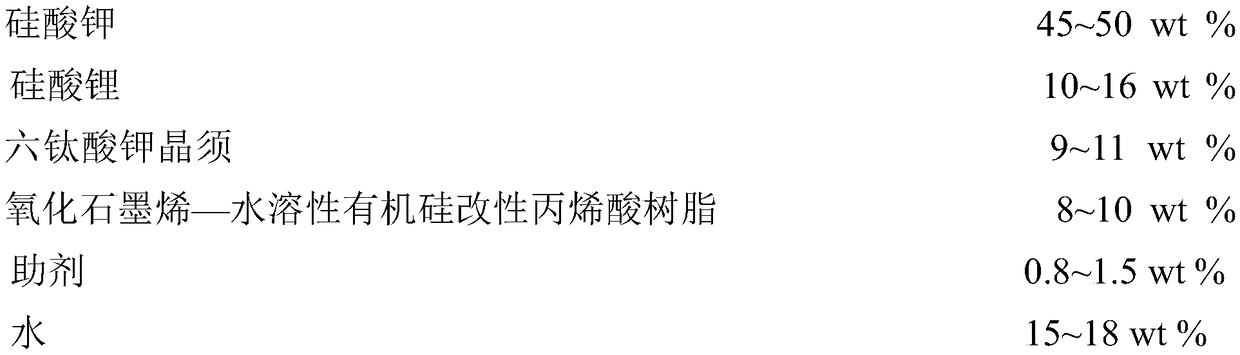

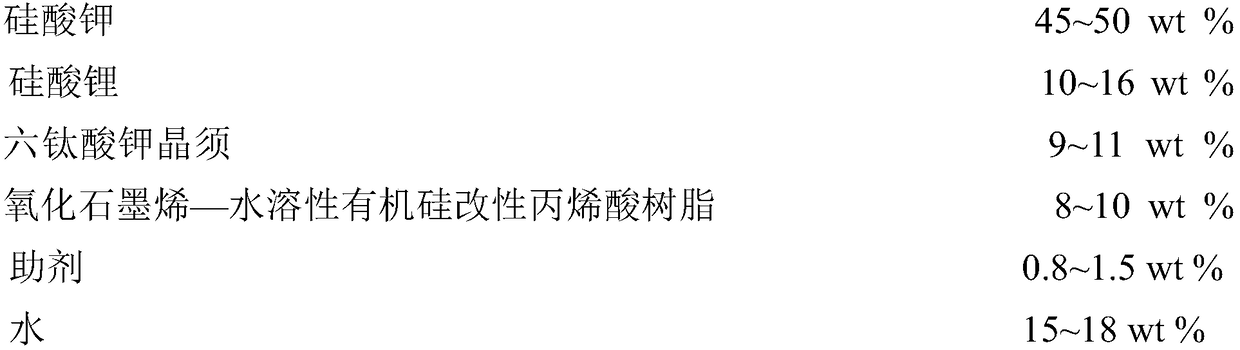

[0046] Step 3: Coating graphene oxide-water-soluble silicone modified acrylic resin primer layer coating on the above chemical coating, with a thickness of 5-8 μm, drying and curing at 200°C to obtain graphene oxide-water-soluble silicone Modified acrylic resin primer layer;

[0047] Step 4: Paste the PET film on the graphene oxide-water-soluble silicone modified acrylic resin primer layer on the front with polyurethane hot melt adhesive, and cool down;

[0048] Step 5: Paste the PE film with a thickness of 40 μm directly on the PET film to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com