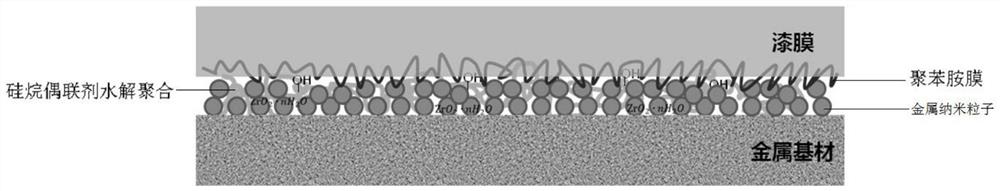

A kind of polyaniline-silane-nanometer ceramic composite surface treatment agent

A composite surface treatment and nano-ceramic technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as environmental hazards, high dependence, and weak physical bonding ability of film corrosion resistance, and achieve reduced metal corrosion and strong rigidity , good compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

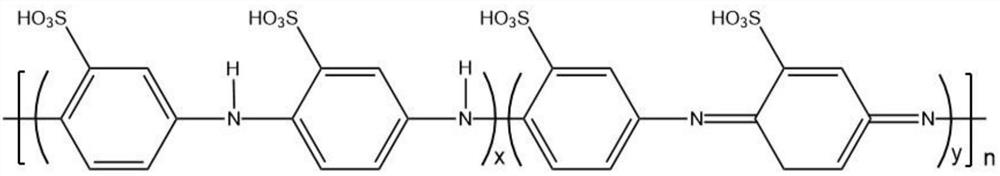

[0022] Preparation of polyaniline-silane-nano ceramic composite surface treatment agent: the sulfonic acid group modified polyaniline (number average molecular weight is 20000), 200mg / L methoxyl modified polyaniline (number average molecular weight) that mass concentration is 500mg / L 10000), 400mg / L dispersed polyaniline nanoparticles (nano-scale polyaniline synthesized in gas phase, particle size is 15nm, PDI=0.1, number average molecular weight is 20000), 300mg / L fluorozirconic acid (calculated as zirconium) , 100 mg / L zirconyl nitrate (calculated as zirconium), 10 mg / L γ-aminopropyltrimethoxysilane, 10 mg / L alkyl glycoside and the remainder of deionized water were mixed evenly and stirred until the solution was clear and transparent, and polyaniline- Nano-ceramic composite surface treatment agent.

[0023] Use nitric acid aqueous solution to adjust the pH value of the composite surface treatment agent to 3.00±0.01, and use this composite surface treatment agent to soak the ...

Embodiment 2

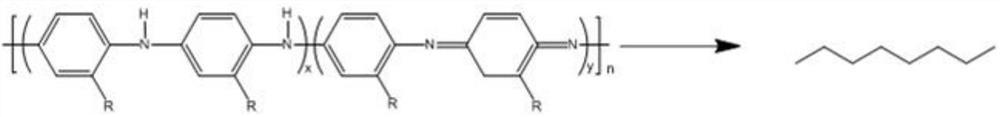

[0042] Prepare polyaniline-silane-nano-ceramic composite surface treatment agent: the dispersive polyaniline nano-particle (being the nanoscale polyaniline of vapor phase synthesis, particle diameter is 15nm, PDI=0.1, number-average molecular weight is 40mg / L with mass concentration 20000), 10mg / L ethoxy-modified polyaniline (number-average molecular weight 8000), 100mg / L amino-modified polyaniline (number-average molecular weight 12000), 5mg / Lγ-aminopropylmethyldiethoxy Silane, 100 mg / L potassium fluozirconate (calculated as zirconium), 5 mg / L sodium lauryl sulfate and the remainder of deionized water were mixed evenly and stirred until the solution was clear and transparent to obtain a polyaniline-nano-ceramic composite surface treatment agent.

[0043]The prepared polyaniline-silane-nanometer ceramic composite surface treatment agent is adjusted to pH 4.20±0.01 with ammonia solution. Use this treatment solution to soak the metal sample after degreasing pretreatment and wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com