LAVAL pipe jet air stirring device

A technology of stirring device and Rafael tube, used in transportation and packaging, chemical instruments and methods, dissolution, etc., can solve problems such as easy damage of mechanical seals and slurry leakage, and achieve high reliability, fewer components, and reduced wear and tear. and the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

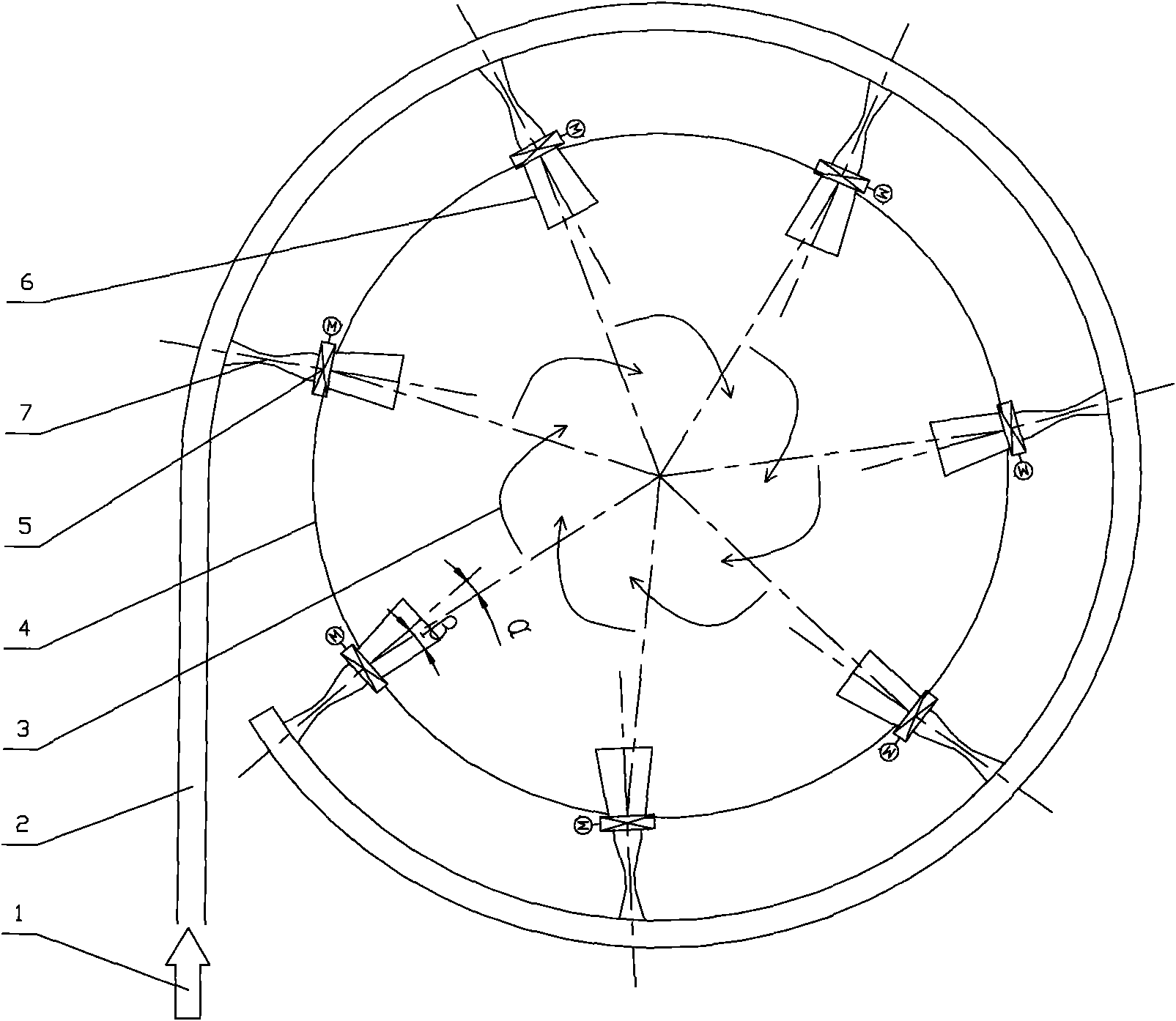

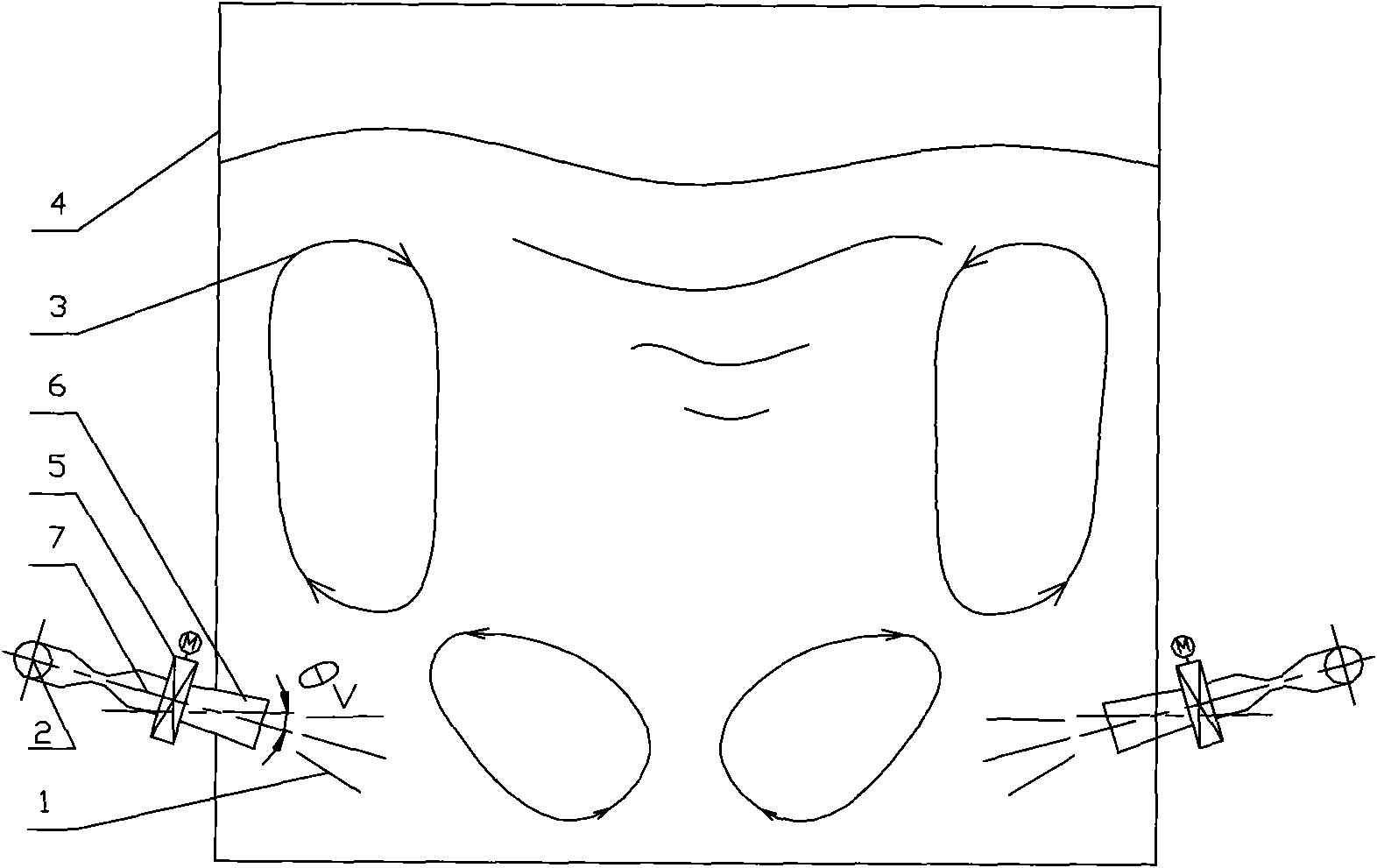

[0014] The Rafal tube jet air stirring device is composed of an air distributor 2 and a jet device, wherein the jet device is composed of a Rafal tube 7 , a valve 5 and a turbulence tube 6 . The air distributor is generally arranged on the peripheral wall of the slurry tank, and then the jet device is evenly arranged according to the diameter of the slurry tank.

[0015] Air or compressed air 1 is evenly distributed to each Rafal tube 7 through the air distributor 2, and the air is accelerated to the velocity V (10m / s<V<100m / s) through the Rafal tube 7, and the accelerated air enters the turbulent flow The tube is sprayed into the slurry, and the air rises and rolls under the action of turbulent flow and buoyancy, driving the surrounding slurry to turn and roll to achieve the effect of full stirring.

[0016] The role of valve 5 is to control the amount of injected air, thereby controlling the intensity of stirring, and in addition, it can also prevent the backflow of slurry d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com