Rolling propelling device for perforating pipe string of horizontal well with upward inclination angle

A technology of propulsion device and horizontal well, which is applied to drilling pipes, casings, drilling equipment, etc., can solve the problems of low screening efficiency and easy blockage of screens, and achieve smooth conveying process, reduce friction resistance, and reduce the possibility of wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

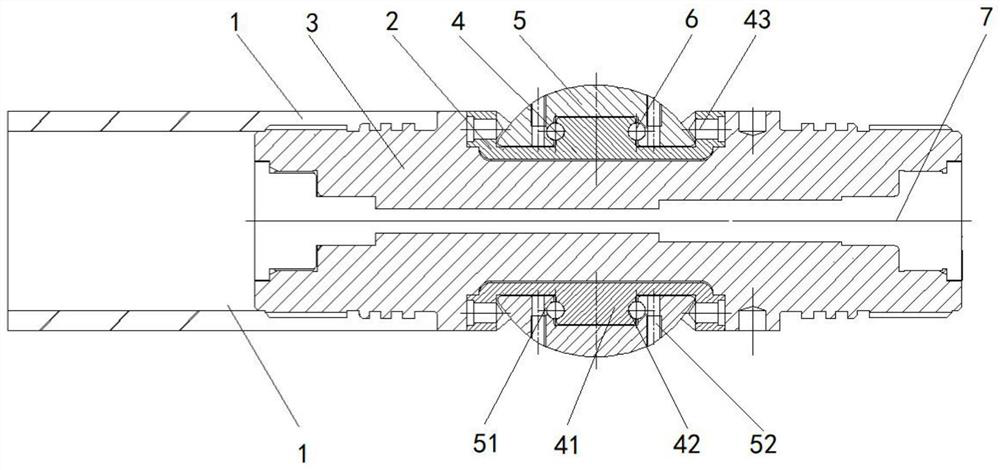

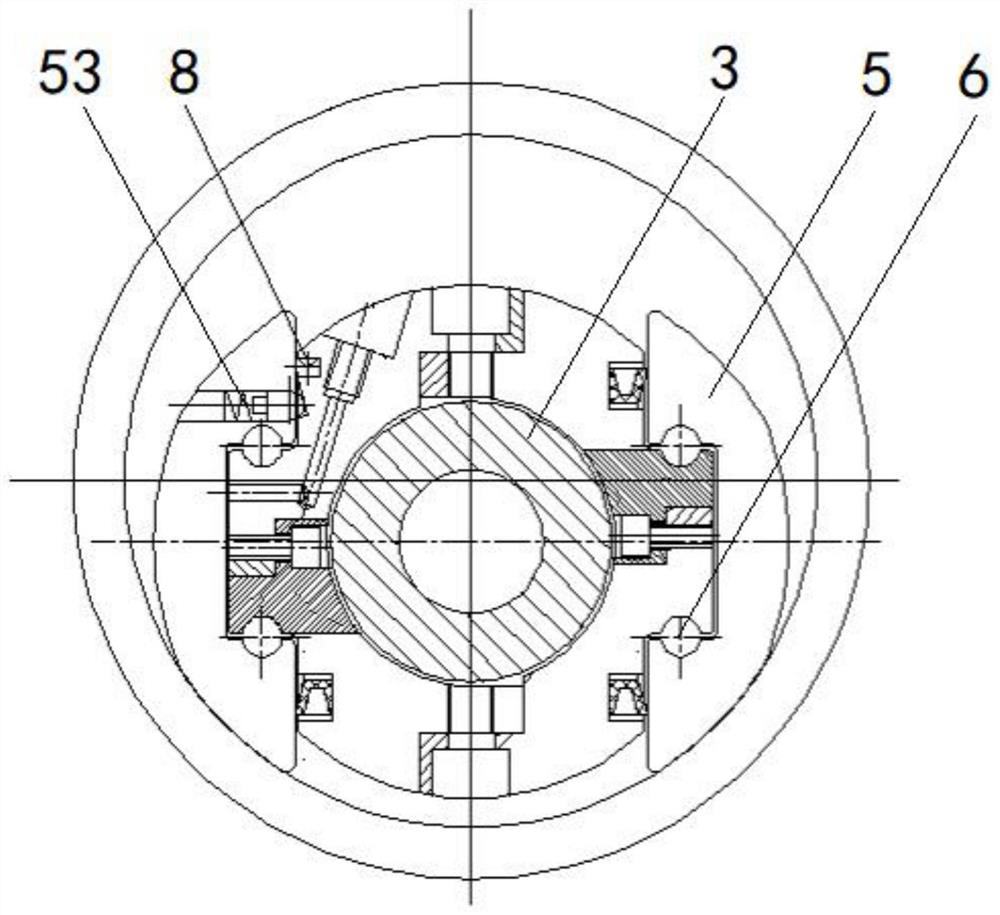

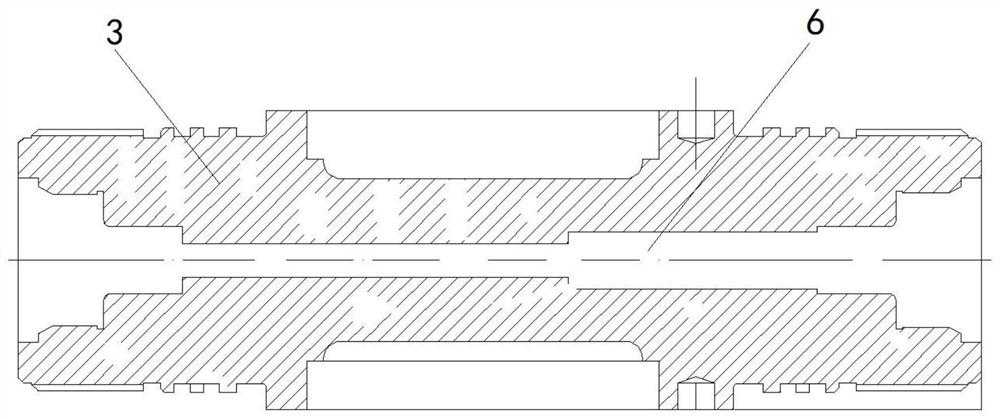

[0037] combine Figure 1-12 This embodiment provides a rolling propulsion device for a perforating pipe string in an up-dip horizontal well, which includes a perforating gun barrel 1 and a rolling propulsion joint 2, and the rolling propulsion joint 2 is detachably connected to two adjacent perforating guns between pipes 1; the rolling push joint 2 includes a joint body 3, a rotating body 4, a rolling body 5, a steel ball 6 and a conductive sealing communication component 7; the rotating body 4 is connected to the side wall of the joint body 3; The rolling body 5 is rollingly connected to the rotating body 4 through the steel ball 6; the rolling body 5 is used for supporting and eccentrically centralizing the perforating barrel; .

[0038] The rolling push joint 2 and the perforating gun barrel 1 are fastened and sealed by a threaded sealing ring, and the rolling bodies symmetrically arranged on both sides of the rolling push joint support the pipe string structure formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com