Method for reducing electrostatic level in fluidized bed reactor

A fluidized bed reactor and fluidized bed technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problem of ineffective neutralization of charges, infrequent use of static elimination devices, and adverse effects of molecular weight/molecular weight distribution, etc. problem, to achieve the effect of easy realization and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

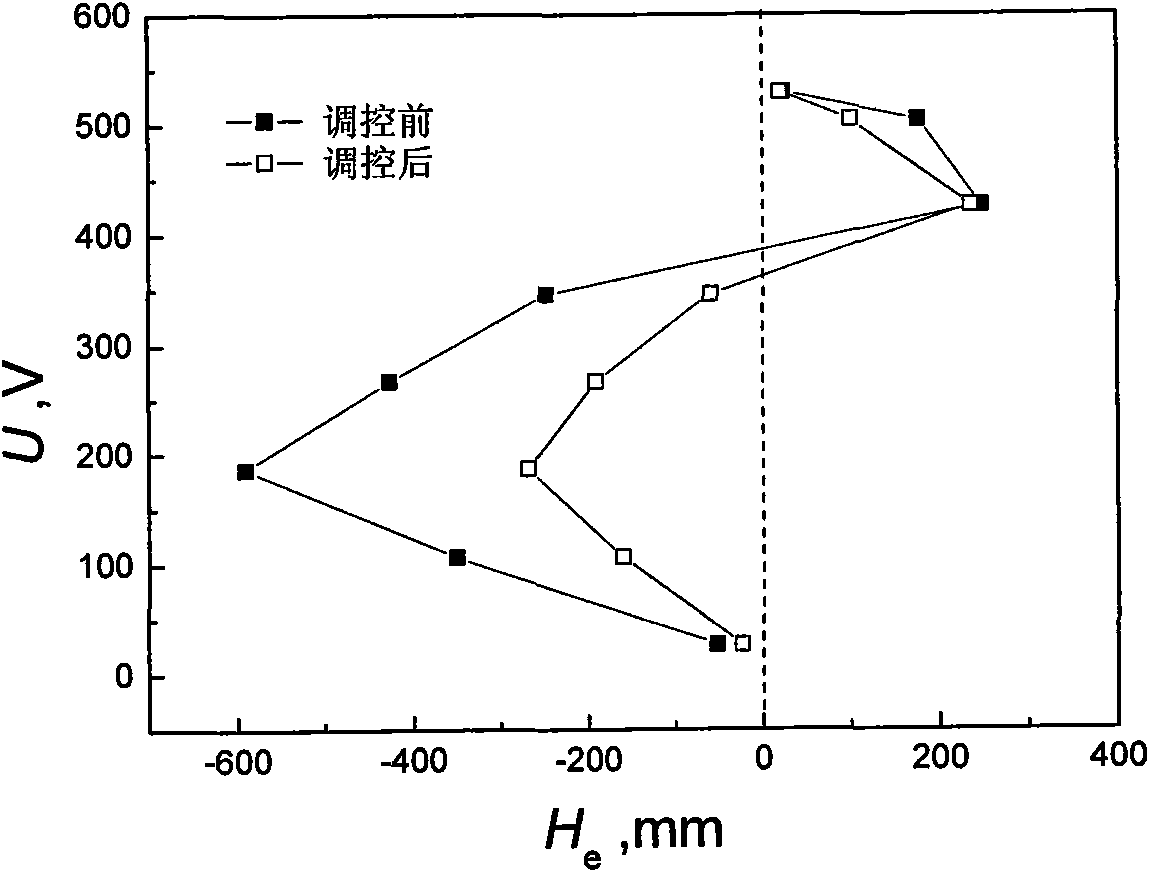

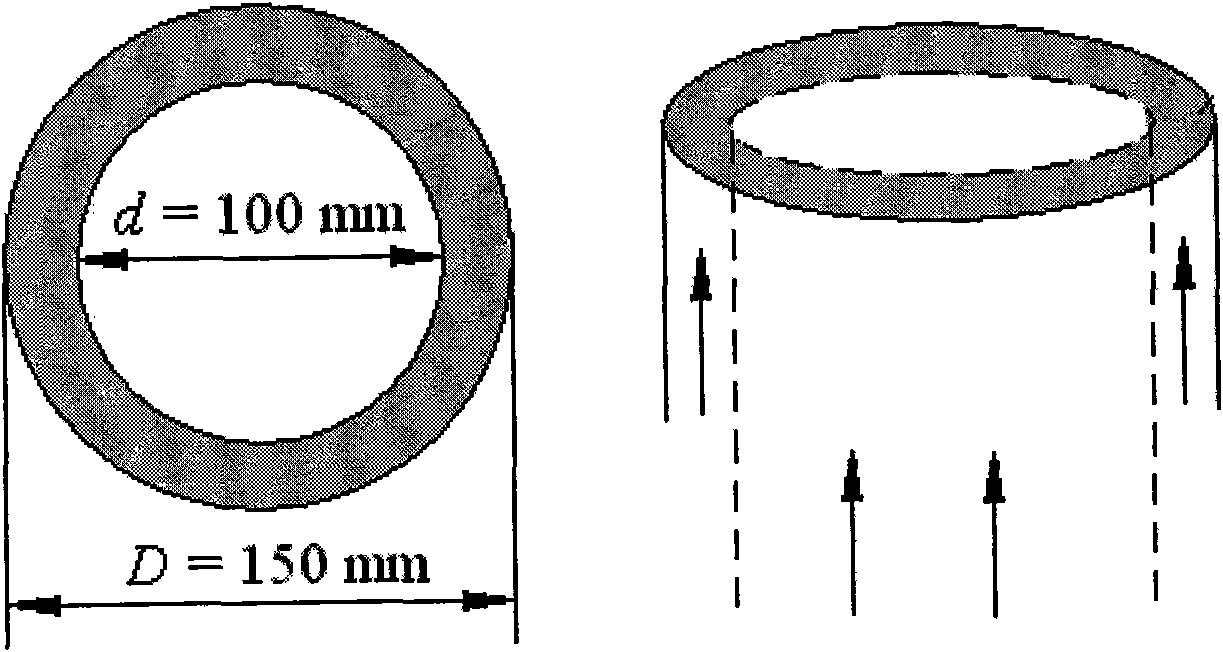

Embodiment 1

[0038] In a gas-solid fluidized bed with a height of 1000mm and an inner diameter of 150mm made of plexiglass, the distribution plate is a porous flat plate with a diameter of 150mm, the aperture is 2.0mm, and the opening ratio is 2.6%, and the distribution plate is composed of a diameter of 100mm. The ring composition (such as image 3 As shown, the holes in the distribution plate are not marked), which can control the superficial gas velocity in two zones. Air is used as the fluidizing gas, and the superficial gas velocity is 0.5m / s. The fluidizing medium is sieved and mixed LLDPE particles. After sieving, LLDPE becomes five kinds of particles with different average particle sizes of P1, P2, P3, P4, and P5. : Mix in a ratio of 10:10. The static bed height is 300mm, the sampling frequency is 100Hz, and each sampling time is 300s. Change the height of the electrostatic detector to 27mm, 107mm, 187mm, 267mm, 346mm, 426mm, 504mm, and 529mm above the distribution plate, and m...

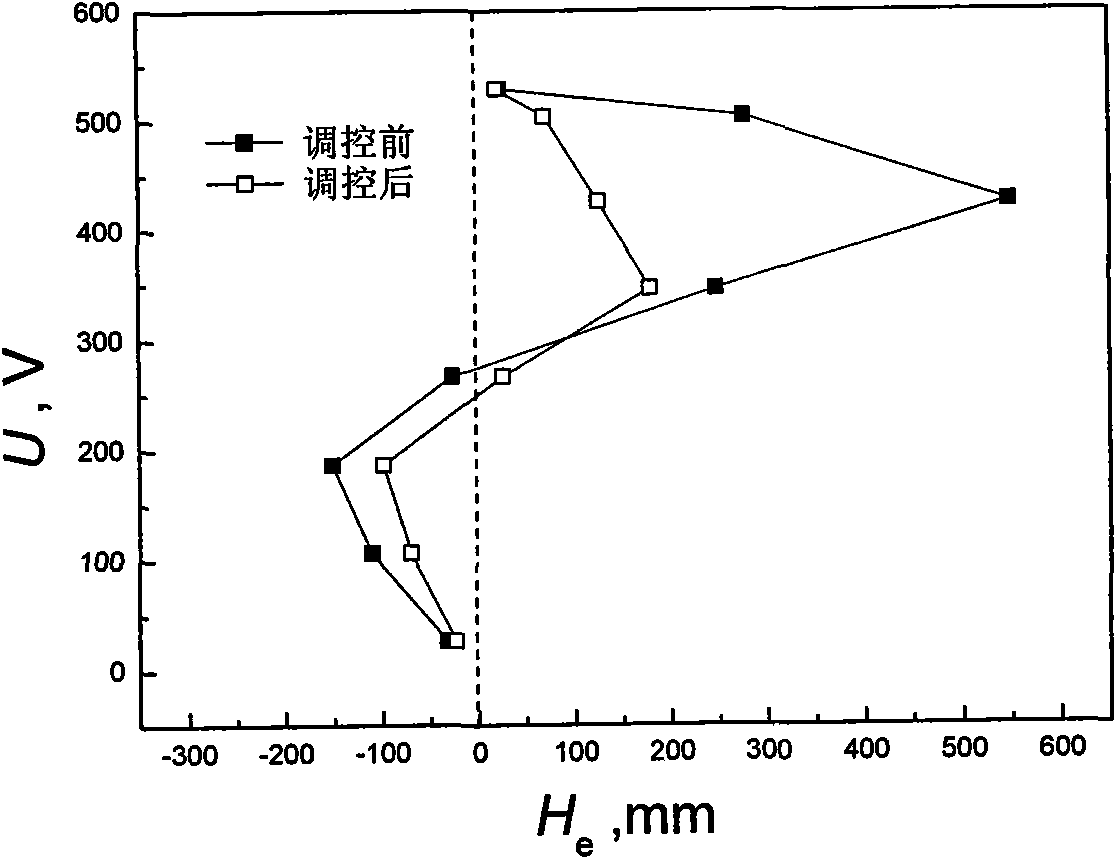

Embodiment 2

[0043]In a gas-solid fluidized bed made of plexiglass with a height of 1000mm and an inner diameter of 150mm, the distribution plate is a porous flat plate with a diameter of 150mm and a hole diameter of 2.0mm. The opening rate is 2.6%. The distribution plate is composed of an inner circle with a diameter of 100mm and an outer ring. , which can control the superficial gas velocity in two regions. Air is used as the fluidizing gas, and the superficial gas velocity is 0.5m / s. The fluidizing medium is sieved and mixed LLDPE particles. After sieving, LLDPE becomes five kinds of particles with different average particle sizes of P1, P2, P3, P4, and P5. : Mixed in a ratio of 20:50. The static bed height is 300mm, the sampling frequency is 100Hz, and each sampling time is 300s. Change the height of the electrostatic detector to 27mm, 107mm, 187mm, 267mm, 346mm, 426mm, 504mm, and 529mm above the distribution plate, and measure the electrostatic potential distribution in the fluidiz...

Embodiment 3

[0046] In high 12000mm, internal diameter 3050mm, distribution plate is perforated plate (diameter of inner circle is 2000mm), and aperture is in the industrial pilot test fluidized bed device of 2.5% (gas-phase process technology production polyethylene) with 16mm aperture ratio, reaction temperature is 87°C, the electrostatic detector is placed 2100mm above the distribution plate and 5mm away from the wall. The superficial gas velocity is 0.7m / s, the sampling frequency is 100Hz, and each sampling time is 100s. Calculate the collected electrostatic signal to find the steady-state electrostatic potential U s .

[0047] Under abnormal working conditions, the negative electrostatic potential is greater than 2800V, that is, the positive potential level in the fluidized bed is relatively high, so increasing the distribution plate is conducive to the increase of the negative electrostatic potential level, that is, the gas velocity in the outer ring area to 0.75m / s, and the reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com