Method for iron internal electrolysis treatment of hard-degradation organic wastewater strengthened by magnetic catalyst and used fillings thereof

A magnetic catalyst, organic wastewater technology, applied in the fields of magnetic field/electric field water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. The effect of reducing volume and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

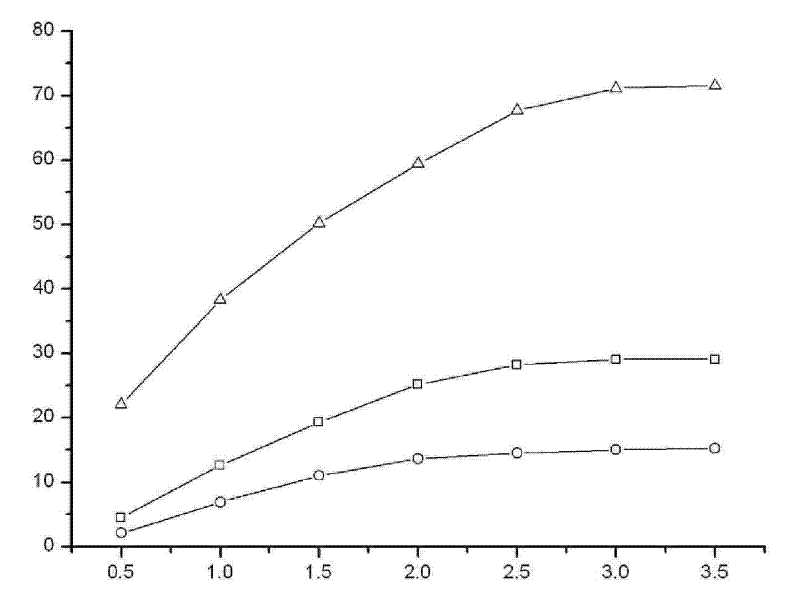

Image

Examples

Embodiment 1

[0034] Ferrous chloride and ferric chloride are used as raw materials, and the molar ratio is Fe 2+ : Fe 3+=1:1 solution, add 100-mesh powdery nucleating substance, stir well, heat the solution to 60°C, add sodium hydroxide to PH=12 under continuous stirring, place it in a water bath at 95°C for 4 hours, Wash the product with deionized water until neutral, after magnetic separation, dry at 130°C for 4 hours, add potassium sodium tartrate 80g / L, sodium carbonate 15g / L, copper sulfate 10g / L, sodium hydroxide 25g / L copper salt solution medium, fully stirred, water bath to 35°C, added formaldehyde under rapid stirring until its concentration in the copper salt was 8g / L, stirred for 40 minutes, washed with deionized water until neutral, and dried to make copper-plated magnetic particles. The prepared copper-plated magnetic particles and iron filings were weighed at a mass ratio of 1:10, and the air flow rate (that is, the aeration rate, the same below) was 20 L / min, and the reacti...

Embodiment 2

[0036] Ferrous sulfate and ferric sulfate are used as raw materials, and the molar ratio is Fe 2+ : Fe 3+ =1:1 solution, add 200-mesh powdery nucleating substance, stir well, heat the solution to 80°C, add sodium hydroxide to pH=13 under continuous stirring, place it in a water bath at 100°C for 3 hours, Wash the product with deionized water until neutral, after magnetic separation, dry at 160°C for 3 hours, add potassium sodium tartrate 100g / L, sodium carbonate 30g / L, copper sulfate 20g / L, sodium hydroxide 35g / L copper salt solution medium, fully stirred, water bath to 45°C, add formaldehyde under rapid stirring until its concentration in the copper salt is 12g / L, stir for 30 minutes, wash with deionized water until neutral, and dry to make copper-plated magnetic particles. The prepared copper-plated magnetic particles and iron filings were weighed with a mass ratio of 1:6, and the air flow rate was 15L / min, and the reaction time was 3h, and the COD of pH=3 was 1340mg / L p-ni...

Embodiment 3

[0038] Ferrous chloride and ferric sulfate are used as raw materials, and the molar ratio is Fe 2+ : Fe 3+ =1:1 solution, add 100-mesh powdery nucleating substance, stir fully, heat the solution to 70°C, add potassium hydroxide to pH=12 under continuous stirring, place it in a water bath at 98°C for 3 hours, Wash the product with deionized water until neutral, after magnetic separation, dry at 150°C for 4 hours, add potassium sodium tartrate 90g / L, sodium carbonate 20g / L, copper sulfate 15g / L, sodium hydroxide 30g / L copper salt solution medium, fully stirred, water bath to 40°C, added formaldehyde under rapid stirring until its concentration in the copper salt was 10g / L, stirred for 50 minutes, washed with deionized water until neutral, and dried to make copper-coated magnetic particles. The prepared copper-plated magnetic particles and iron filings were weighed at a mass ratio of 1:7. Under the conditions of an air flow rate of 20 L / min and a reaction time of 3 h, the COD of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com