One-dimensional heat exchange phase change process testing device and method of waxy phase change material

A phase change material and process testing technology, which is applied in the testing of fuel supply tank devices, fluid pressure actuating devices, and fluid pressure actuating systems, etc. Improve the effect of close contact, high degree of automation, and strong data continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below with reference to the accompanying drawings and specific examples. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

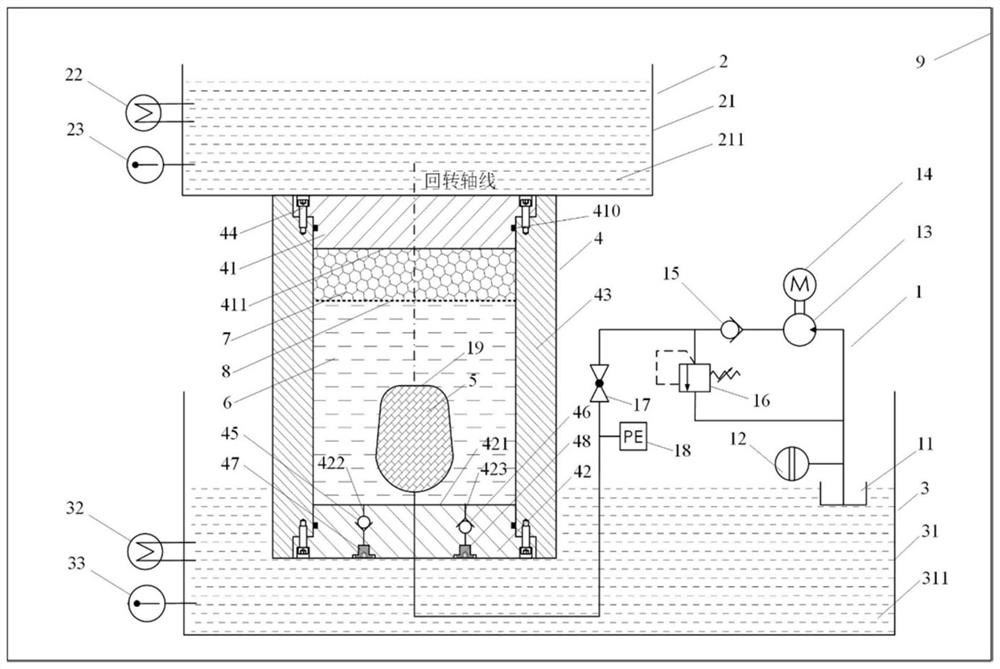

[0041] like figure 1 , The phase change material is a waxy type one-dimensional phase change heat exchange testing device 1 comprises a hydraulic system, the pool 2, the sink 3, 4 sealpot four parts, a hydraulic system 1 comprises a tank 11, level sensor 12, the hydraulic pump 13, the driving motor 14, the check valve 15, pressure regulating valve 16, hand-off valve 17, pressure sensor 18, the rubber bladder 19; the basin 2 includes an upper water tank 21, 22, a temperature sensor on the cold switch 23; the sink 3 includes a lower tank 31, hot and cold switch 32, a temperature sensor 33; 4 includes a thermally conductive seal pot cover 41, the thermally conductive cover 42, the ceramic wall 43, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com