Novel indium-based efficient heat-conducting gasket

A heat conduction gasket and indium sheet technology, which is applied in the field of new indium-based high-efficiency heat conduction gaskets, can solve the gap between the heat conduction gasket and the chip and the radiator, poor wettability between the heat conduction paste and the thermal interface material, and the reduction of the heat conduction of the liquid metal Effect and other issues, to achieve the effect of reducing contact thermal resistance, high power heat dissipation requirements, and improving contact tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment proposes a new type of cymbal -based high -efficiency thermal pads. The preparation raw materials for high -efficiency thermal pads include cricket metal and tin tin alloy. The melting point temperature of the Xixi alloy is 60 ° C, which is purchased at Dongguan Optical Titanium Technology Co., Ltd.

[0038] The preparation steps for high -efficiency thermal pads are as follows:

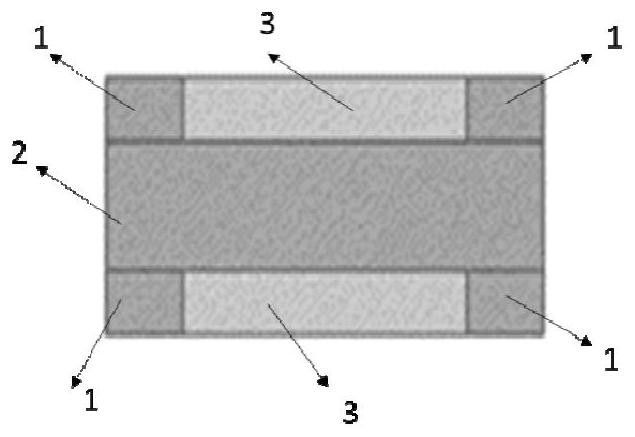

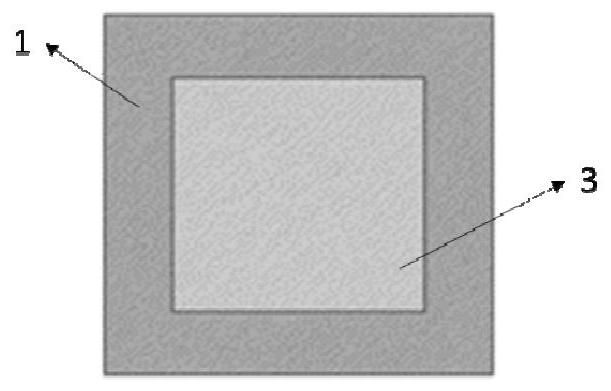

[0039] (1) 属 Metal pressure delay machines are pressed, and the first 铟 1 and thickness of 0.09mm with a thickness of 0.03mm with a thickness of the pressure extension is 0.09mm.

[0040] (2) Press the solid -state tin alloy with pressure extension machine, and the pressure extension is extended into a tin tin alloy tablet with a thickness of 0.03mm 3;

[0041] (3) Take the first cut of the pyramid 1 to cut off, remove the central part, and form a "back" cricket with a central empty cavity;

[0042] (4) Cut the 铟铋 (((3 into a square, the size is the same as the size of the empty ca...

Embodiment 2

[0045] This embodiment proposes a new type of cymbal -based high -efficiency thermal pads. The preparation raw materials for high -efficiency thermal pads include cricket metal and tin tin alloy. The melting point temperature of the Xixi alloy is 60 ° C, which is purchased at Dongguan Optical Titanium Technology Co., Ltd.

[0046] The preparation steps for high -efficiency thermal pads are as follows:

[0047] (1) 属 Metal pressure delay machines are pressed, and the first 铟 1 and thickness of 0.09mm with a thickness of 0.03mm with a thickness of the pressure extension is 0.09mm.

[0048] (2) Press the solid -state tin alloy with pressure extension machine, and the pressure extension is extended into a tin tin alloy tablet with a thickness of 0.03mm 3;

[0049] (3) Take the first cut of the pyramid 1 to cut off, remove the central part, and form a "back" cricket with a central empty cavity;

[0050] (4) Cut the 铟铋 (((3 into a square, the size is the same as the size of the empty ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com