Stainless steel ware polishing solution

A polishing liquid and stainless steel technology, applied in the field of polishing liquid for stainless steel utensils, can solve the problems of waste precipitation, time-consuming and laborious processing, and short service life of the solution, and achieve the effects of less corrosive smoke, reduced production, and improved service life.

Inactive Publication Date: 2010-03-17

GUANGZHOU RES INST OF NON FERROUS METALS

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the chemical polishing solution disclosed in the prior art will produce a large amount of corrosive fumes in the process of polishing stainless steel vessels, which is not conducive to the physical and mental health of production workers; it also produces a large amount of waste deposits, and the follow-up treatment of these deposits is time-consuming and laborious. And the service life of the solution is not long

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010] specific implementation plan

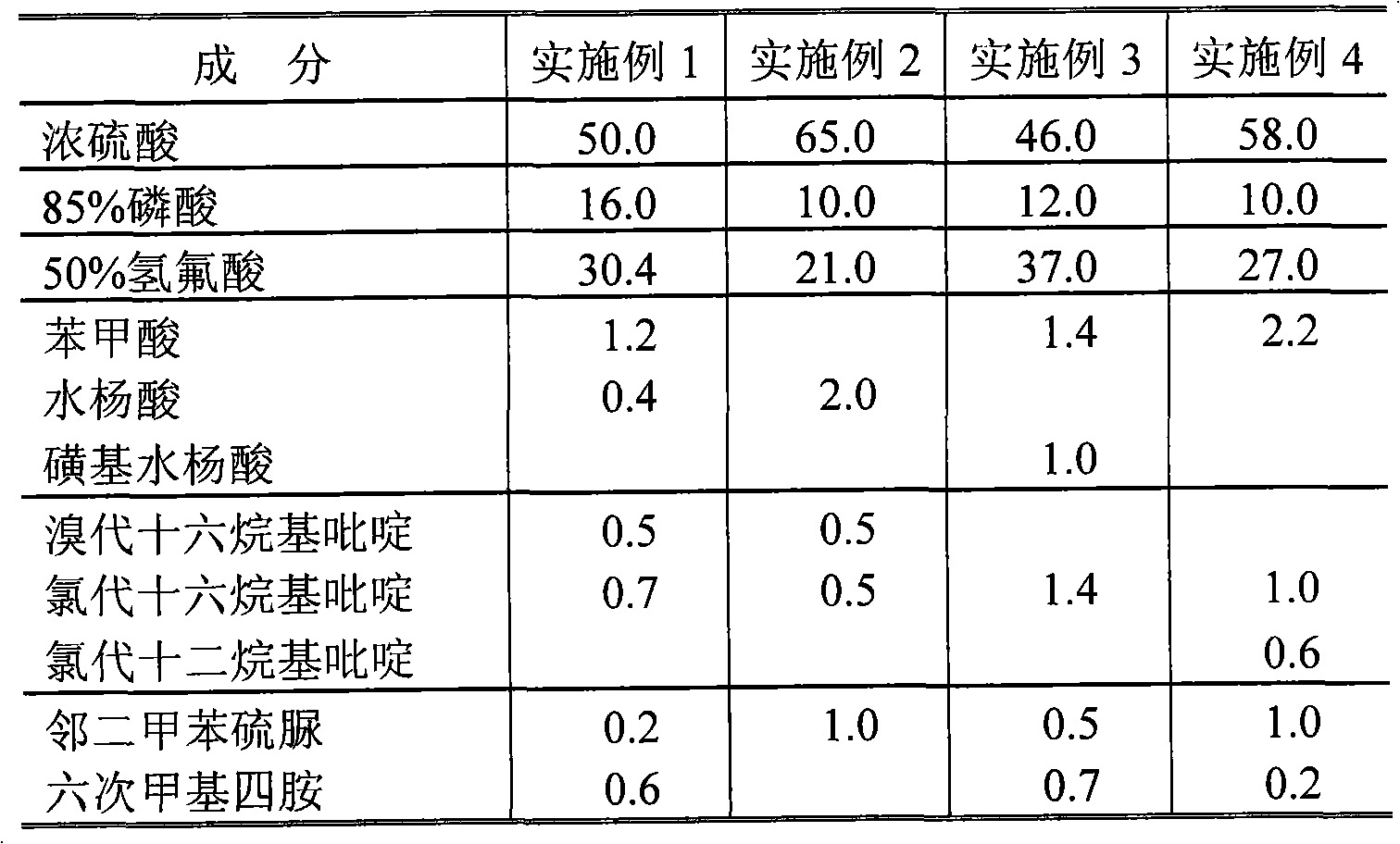

[0011] Table 1 is the weight percentage of each component of Examples 1-4.

[0012] Table 1

[0013]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a stainless steel ware polishing solution which is characterized in that: the polishing solution is formed by concentrated sulfuric acid, 85 percent of phosphoric acid, 50 percent of hydrofluoric acid, benzoic acid and derivant thereof, halogenate alkyl pyridines and inhibiters. Compared with the prior art, the polishing solution produces less corrosive smoke, the production amount of waste material can be reduced by 10 percent, and the service life is improved by 10 percent, thereby being suitable for surface polishing treatment of the stainless steel ware.

Description

technical field [0001] The invention relates to a stainless steel vessel polishing liquid. Background technique [0002] With the continuous improvement of social life, more and more stainless steel products have penetrated into people's daily life, especially stainless steel utensils are gradually becoming the main choice in people's life. In the current production process, stainless steel utensils are mainly made by thermal processing, and thick oxide scales will be formed during the processing. Generally, chemical polishing is used to increase the surface finish of stainless steel utensils. The chemical polishing method can polish parts and products with high precision and complex shapes, and can also prevent local over-corrosion of the stainless steel surface to ensure that the stainless steel surface is smooth and bright. However, the chemical polishing solution disclosed in the prior art will produce a large amount of corrosive fumes in the process of polishing stainl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F3/06

Inventor 赵四勇向杰易振华杨凯珍刘凤美张宇鹏刘师田

Owner GUANGZHOU RES INST OF NON FERROUS METALS

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com