Weighing force transmission mechanism of hanging scale

A weighing sensor and weighing technology, applied in the detailed information of weighing equipment, weighing, weighing auxiliary equipment, etc., can solve the problems of difficult sealing, damage and parallelogram deformation of the scale base, and achieve a reasonable force structure. , The effect of simplifying the sealing structure and improving the strength of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

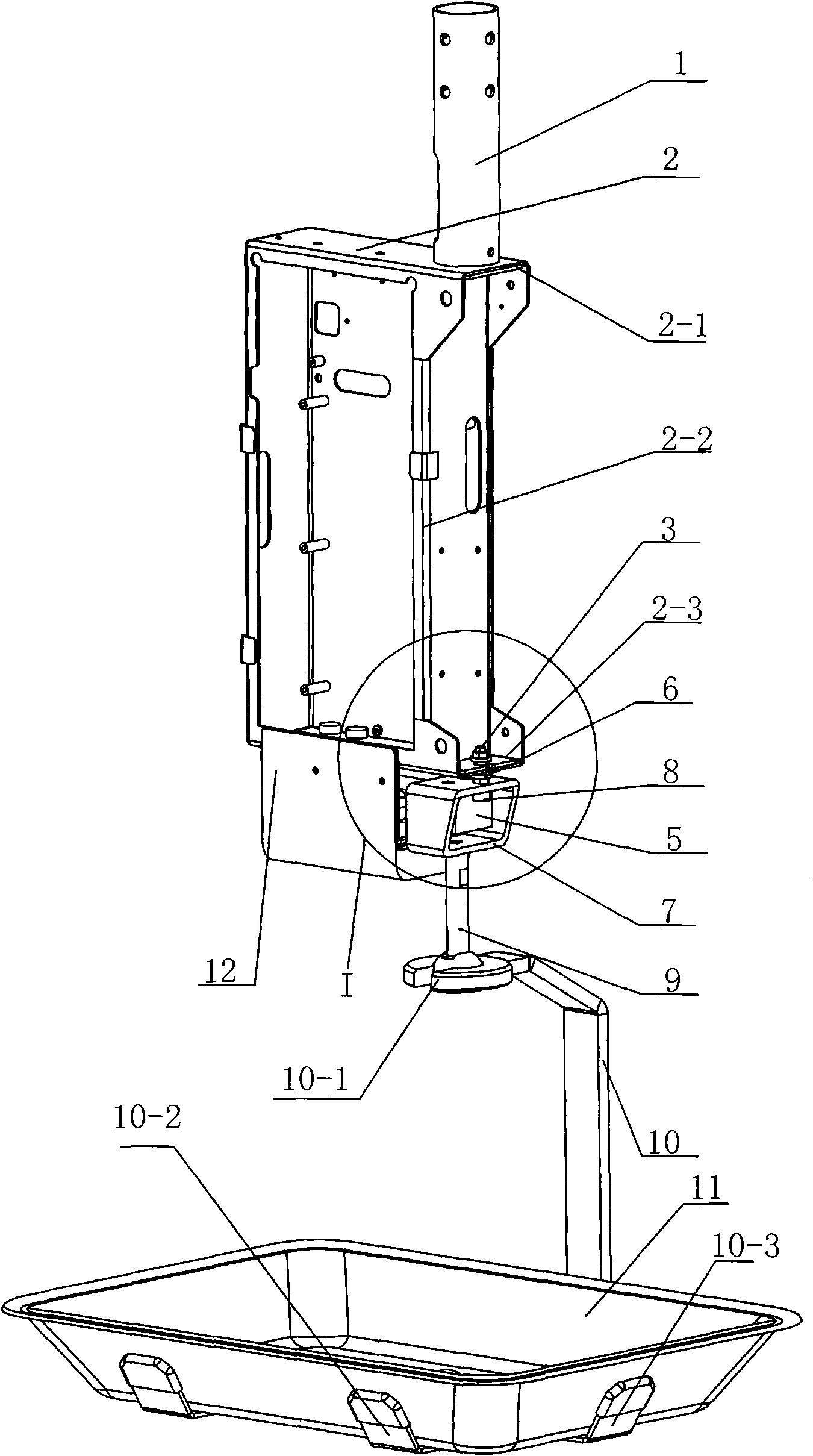

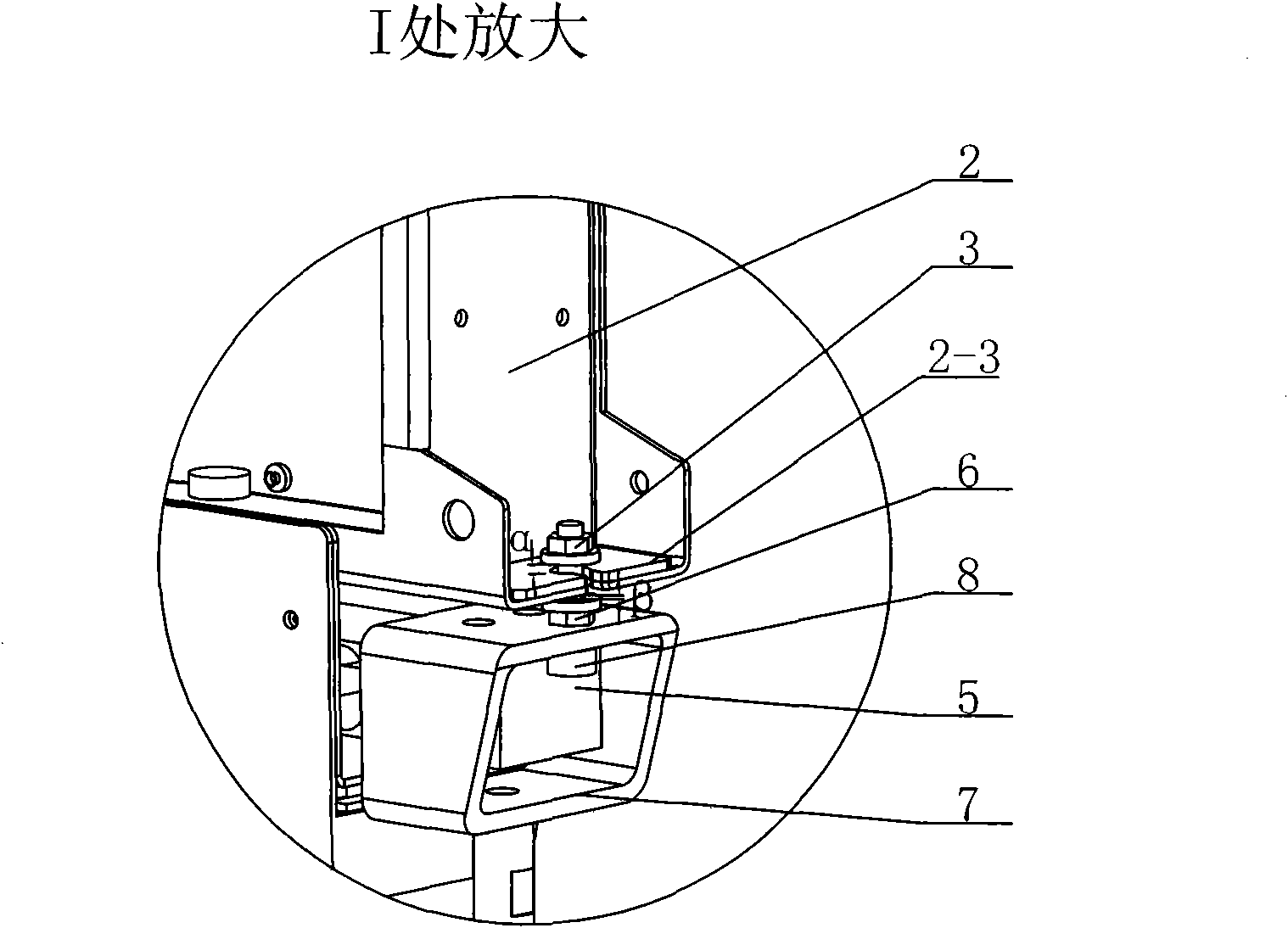

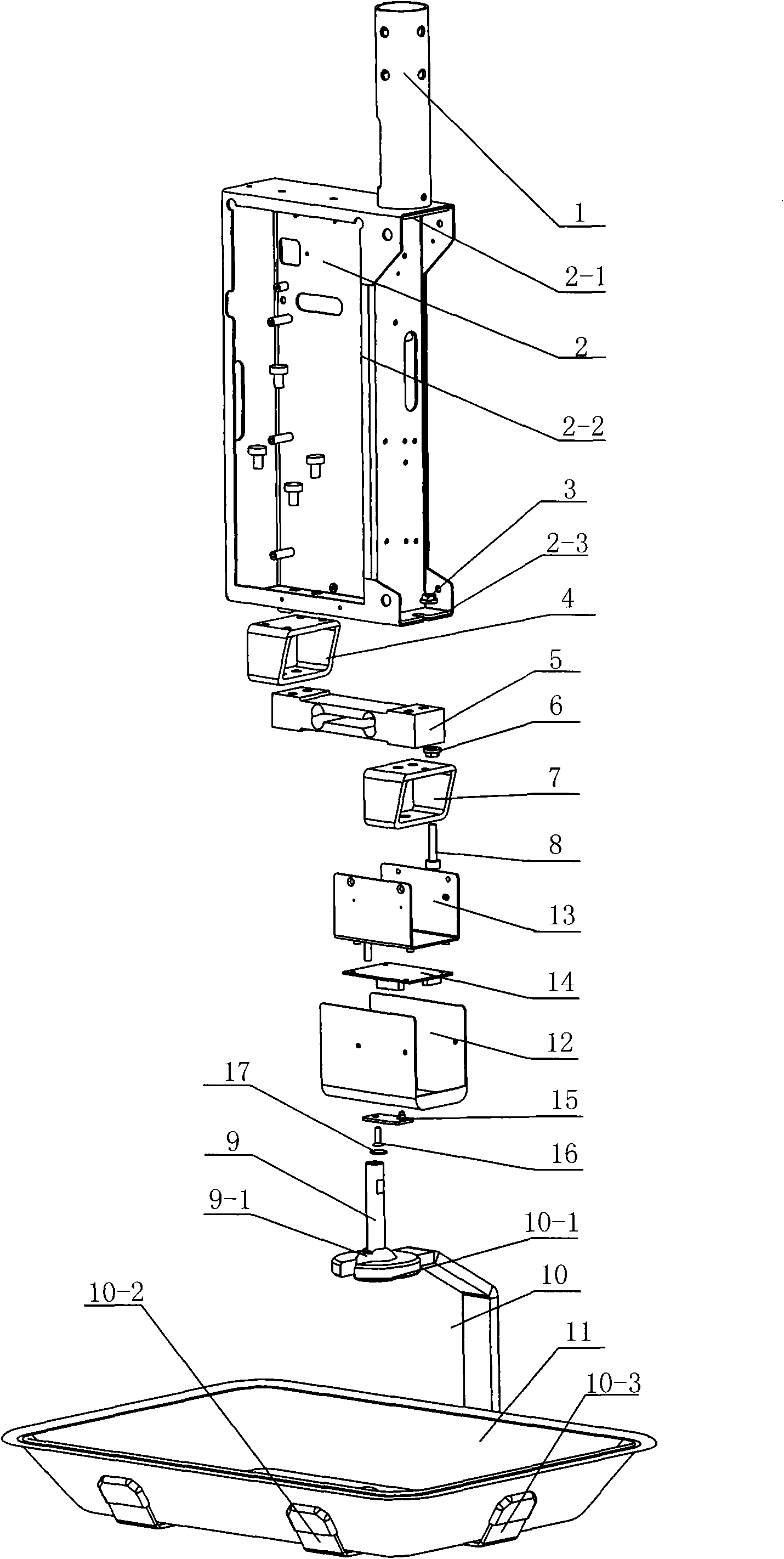

[0019] See Figure 1~4 As shown, the weighing force transmission mechanism of the hanging scale of the present invention includes a boom 1 and a scale base 2, a load cell 5 and a suspension arm 10, the suspension rod 1 is fixed on the top of the scale base 2, and the suspension rod 1 is a round tube , elliptical tube or rectangular tube, the load cell 5 and the suspension arm 10 are installed on the bottom of the scale base 2, the scale base 2 is a box shape with an open front end, and the periphery of the scale base 2 front end has an inner flange 2-2, The upper and lower parts of the same side of the weighing base 2 have an upper bracket 2-1 and a lower bracket 2-3 extending outward, and both the upper bracket 2-1 and the lower bracket 2-3 have reinforcing plates, and the suspender 1 is fixed on the upper bracket 2 -1, or the suspension rod 1 is fixed between the balance base 2 and the upper support 2-1. See figure 1 , 2 As shown, one side of the load cell 5 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com