Test device and test method for measuring aggregative permeability index of sinter bed

A technology of gas permeability and sintered material, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of lack of material layer, achieve high flexibility, reduce edge effect, and improve comparability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

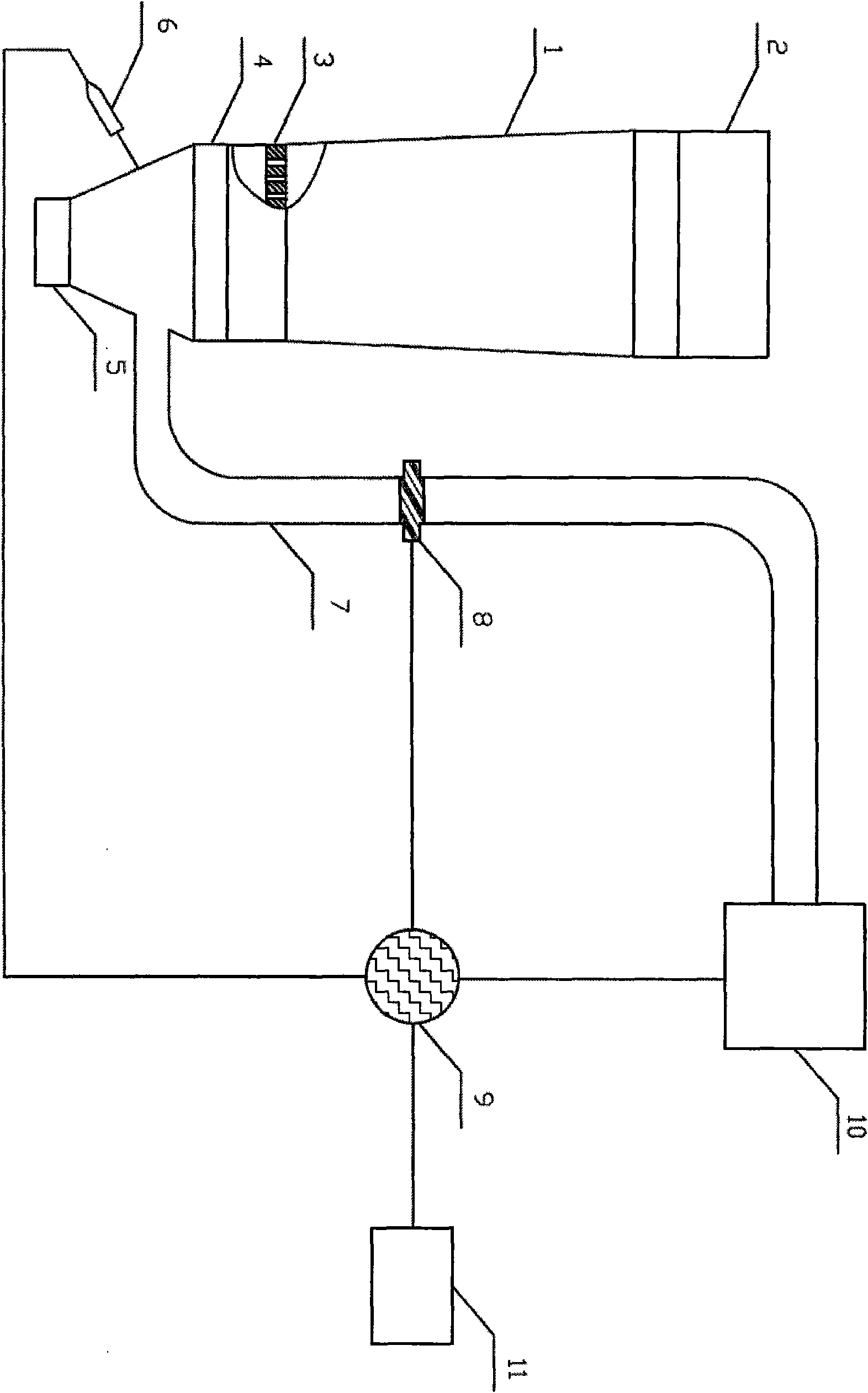

[0033] figure 1 It is a specific embodiment of the present invention.

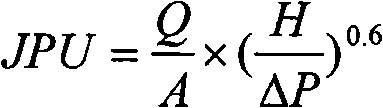

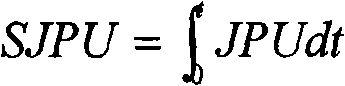

[0034] exist figure 1 In the process, put 10-15 grain grade sinter bottom layer into the main cup body 1, then put the granulated sinter mixture into the main cup body 1 and the auxiliary cup body 2 to the upper edge of the cup body, and put Smooth the material surface. Turn on the exhaust fan 10, open the air volume control program, and gradually increase the air volume from 0 to the set upper limit air volume through the mass flow sensor 8 and the exhaust fan inverter 10. During this process, the computer 11 passes the instrument 9, the pressure sensor 6 and the mass flow rate. The sensor 8 collects negative pressure and air volume data in real time, and calculates the air permeability index of each point through the air permeability index calculation formula. After the flow rate is increased to the set upper limit air volume, the comprehensive air permeability index is calculated according to the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com