Container formation method of valve-regulated lead-acid battery

A lead-acid battery, internalization technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery repair/maintenance, etc., can solve the problems of low production efficiency, long formation time, long production cycle, etc. Efficiency, short time, energy saving effect

Active Publication Date: 2010-03-17

FENGFAN

View PDF0 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] Using this common internal formation process takes 40 to 60 hours in total, and the formation time is longer, the energy consumption is larger, the production cycle is long, and the production efficiency is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

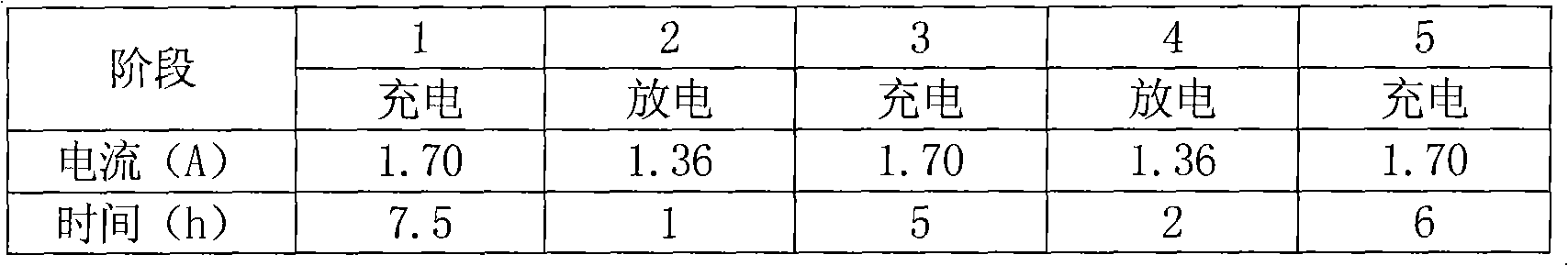

[0025] Embodiment 1. (charged electric quantity is 1.74 times of theoretical electric quantity)

[0026]

Embodiment 2

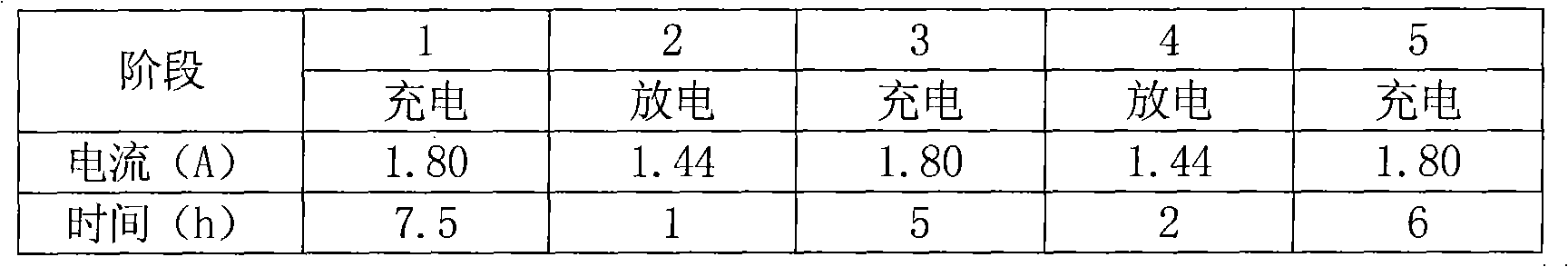

[0027] Embodiment 2: (charged electric amount is 1.84 times of theoretical electric amount)

[0028]

Embodiment 3

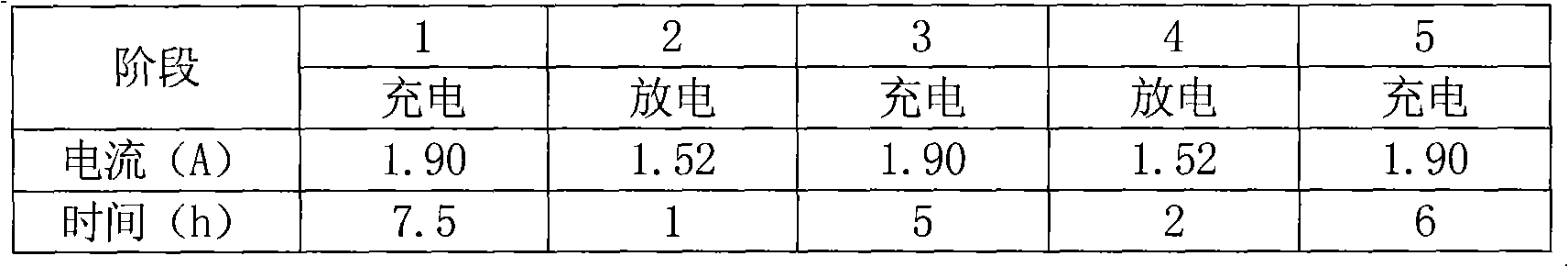

[0029] Embodiment 3: (charged electric amount is 1.94 times of theoretical electric amount)

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a container formation method of a valve-regulated lead-acid battery, which is used for solving the problems of long time consumption and long production cycle of container formation of the valve-regulated lead-acid battery. The method is carried out according to the following steps: a. first charge: the charge time is 7.5h and the current is 1.7-1.9A; b. first discharge: the discharge time is 1h and the current is 1.36-1.52A; c. second charge: the charge time is 5h and the current is 1.7-1.9A; d. second discharge: the discharge time is 2h and the current is 1.36-1.52A;and e. third charge: the charge time is 6h and the current is 1.7-1.9A. The method provides the optimal mixing ratio of current strength to formation time, controls the water temperature during the process, fully forms a plate, forms the optimized container formation technology of the 12V7Ah valve-regulated lead-acid battery, shortens the formation time of the battery to one half of that of the prior art, saves energy consumption and simultaneously, greatly improves production efficiency.

Description

technical field [0001] The invention relates to a storage battery production process, in particular to a valve-regulated lead-acid battery internalization method, and belongs to the technical field of storage batteries. Background technique [0002] Lead-acid batteries have long service life, large capacity, good high-current discharge, high charge acceptance, excellent battery uniformity, small self-discharge, high reaction efficiency, and low raw materials, and have been used until now. While researching and developing new varieties, various manufacturers are constantly exploring ways to improve production efficiency. In the past, in order to shorten the formation time, various explorations have been made, such as increasing the temperature of the formation electrolyte, increasing the formation current or increasing the density of the electrolyte, etc., but the formation temperature is too high, resulting in insufficient initial capacity of the battery; increasing the form...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M10/12H01M10/44

CPCY02E60/126Y02E60/10Y02P70/50

Inventor 马继军梁云超抗立

Owner FENGFAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com