Multifunctional table-type full-automatic chip mounter

A fully automatic, placement machine technology, used in electrical components, electrical components, electrical components to assemble printed circuits, etc., can solve the problems of high work intensity, high difficulty in manual placement, and special operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

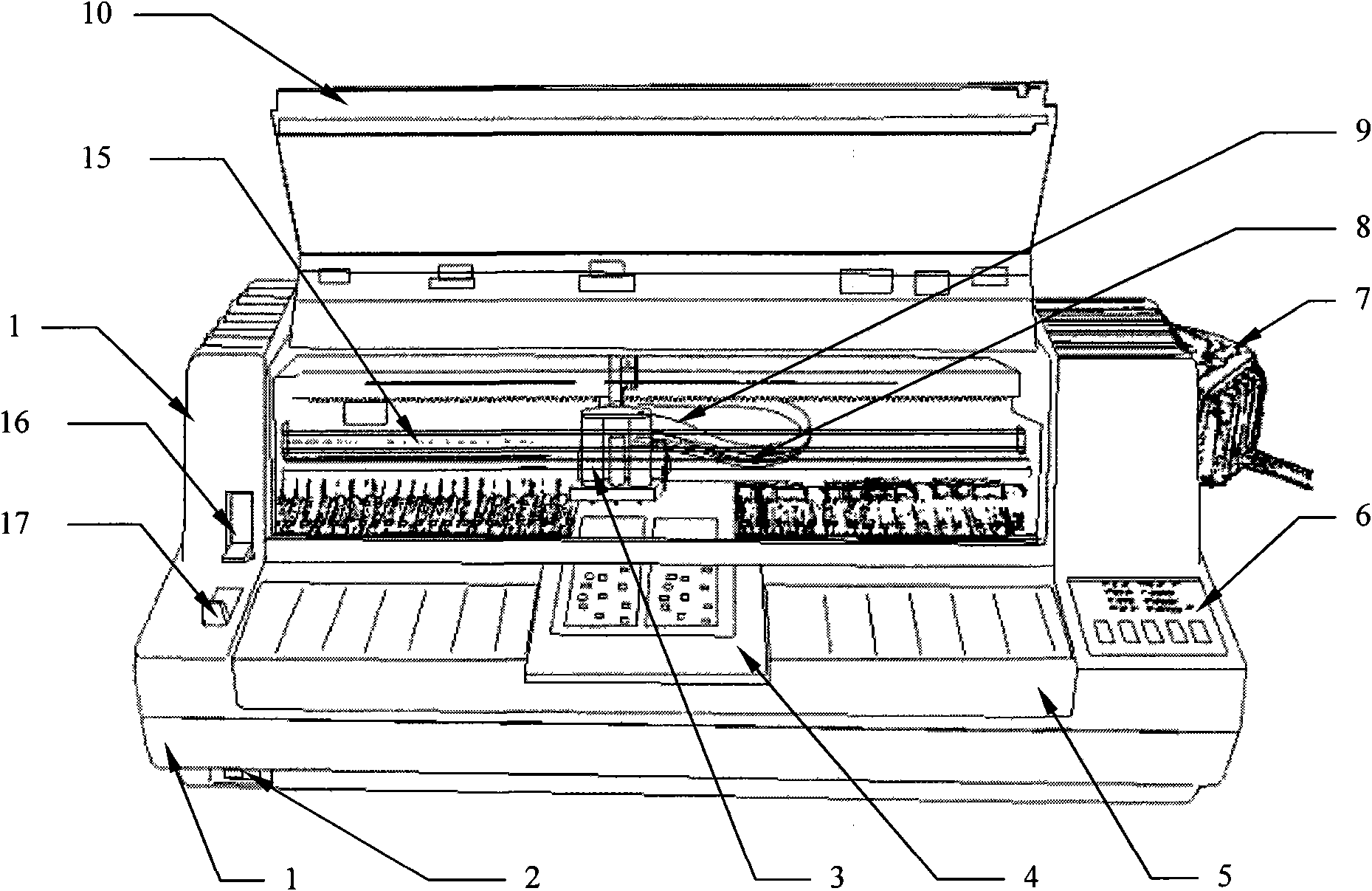

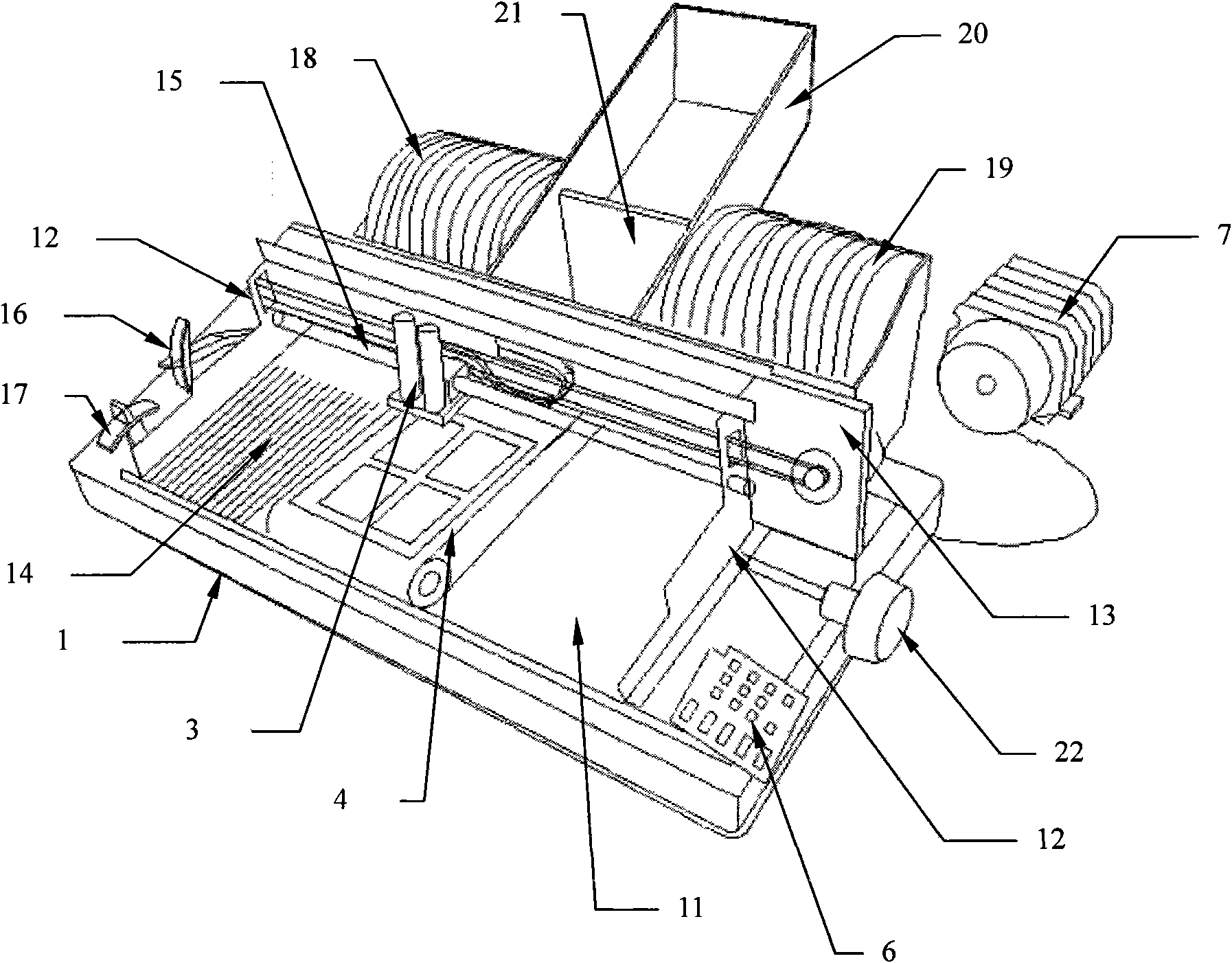

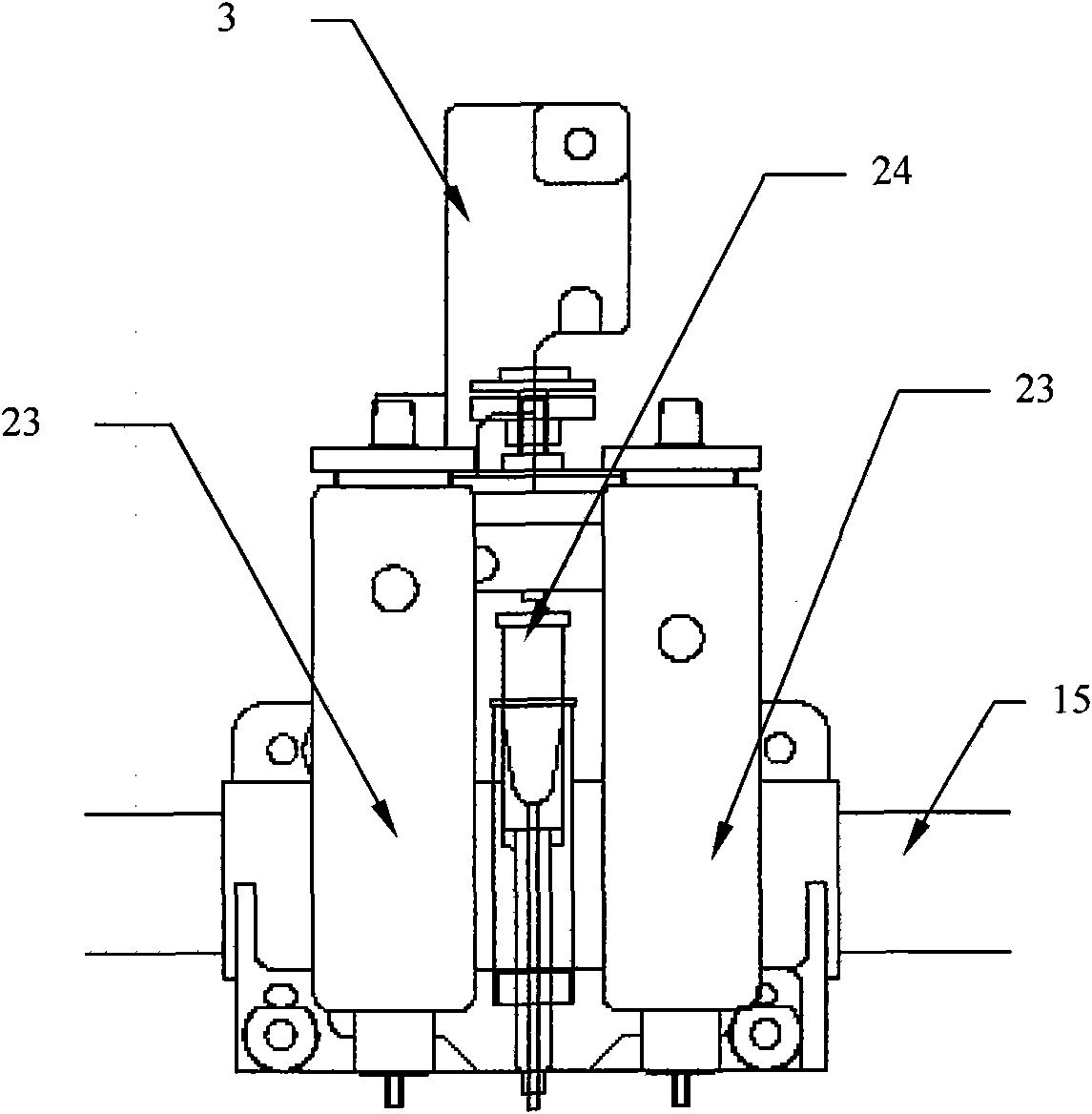

[0019] Implementation methods such as figure 1 , 2 As shown, the bottom edges of the left and right frames 12 are fixed on the frame chassis 11, and the left and right frames 12 are connected and reinforced with frame beams 13. , the trolley 3 carries the placement head 23 and the glue dispenser 24 on the polished rod 15 and slides laterally. The working platform 4 and the feeder 14 are installed on the bottom of the trolley 3 and are fixed on the frame chassis 11. After assembly, they are put into the upper and lower shells 1 to form a completed multifunctional desktop automatic placement machine. Open the front cover 10, and you can observe the parallelism between the traveling track of the trolley 3 and the pick-up port of the feeder with the central adjustment handle 16; open the front cover 5 to load materials, and pull back the pressure handle 17 of the unsealing wheel to lock it All feeders; close the power switch 2 to initialize the whole machine, and supply power to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com