Method and device for sterilising a liquid

A liquid and equipment technology, applied in the fields of application, food science, food preservation, etc., can solve the problems of difficult generation and uniform application, heating, change of physical and chemical properties of liquid, etc., and achieve the effect of easy control and realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

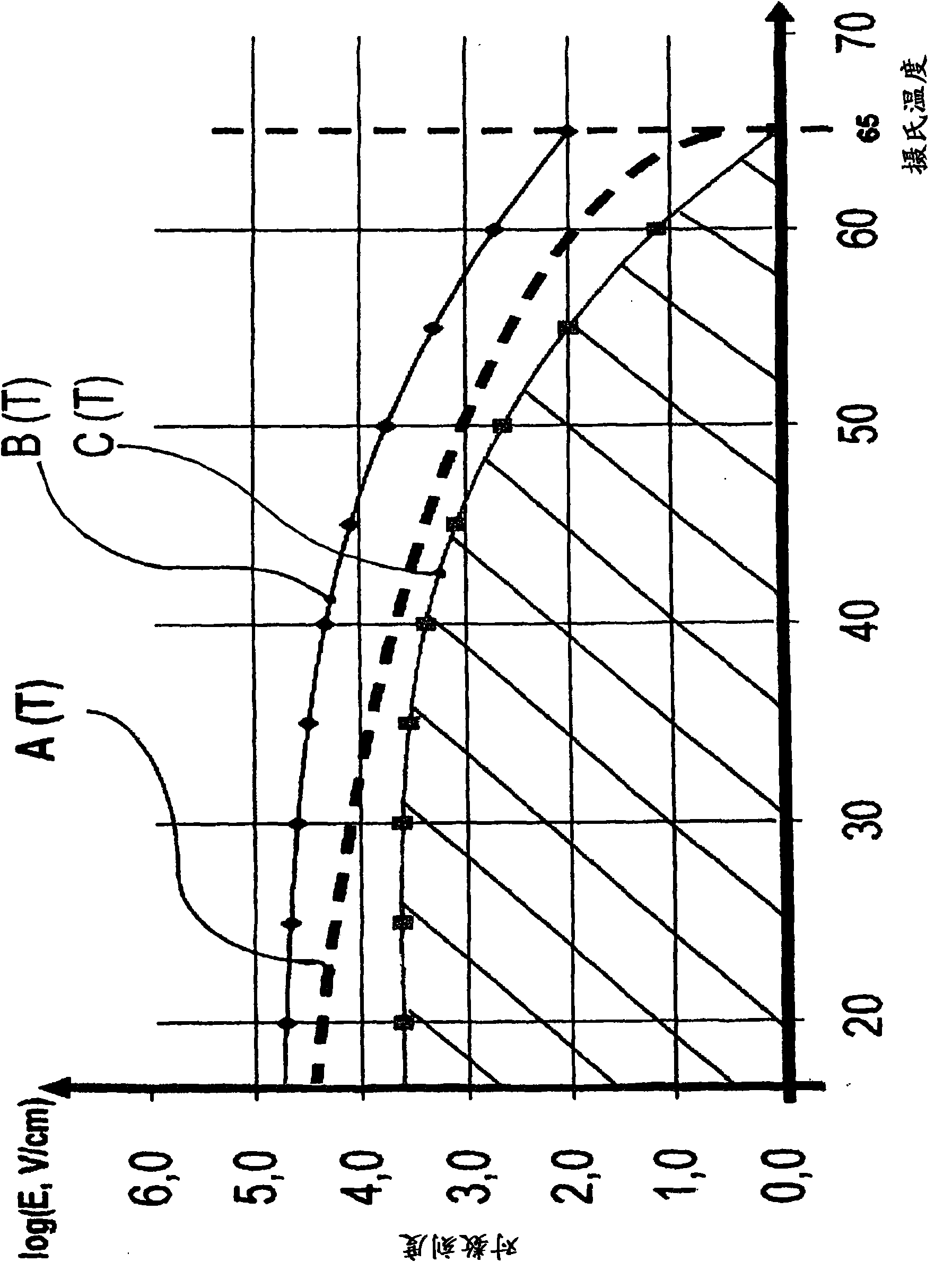

[0054] The sterilization method according to the invention consists in heating the liquid to be treated at a rate greater than 28°C per second to a treatment temperature T between 20°C and 66°C by means of an electric field with a frequency greater than 1 MHz. Depending on the value of the treatment temperature T, the liquid is exposed to an alternating electric field in the form of pulses immediately or slightly later after heating of the liquid, the electric field amplitude E in V / cm is chosen to satisfy the following empirical equation:

[0055] C(T)≤log(E+1)≤B(T)

[0056] in:

[0057] B(T)=-2.340×10 -5 T 3 +1.290×10 -3 T 2 -3.110×10 -2 T+5.0

[0058] C(T)=-4.503×10 -5 T 3 +2.888×10 -3 T 2 -5.900×10 -2 T+4.0

[0059] where T is the processing temperature in degrees Celsius.

[0060] The relationship is defined by figure 1 diagram to describe.

[0061] B(T) represents the upper limit of the electric field amplitude reasonably required under industrial pasteuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com