Compressor and refrigeration device using the same

一种压缩机、压缩机构的技术,应用在压缩机领域,能够解决制冷剂易变成高温、压缩机构故障等问题,达到容易密封、容易更换的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0077] 1. The structure of the scroll compressor

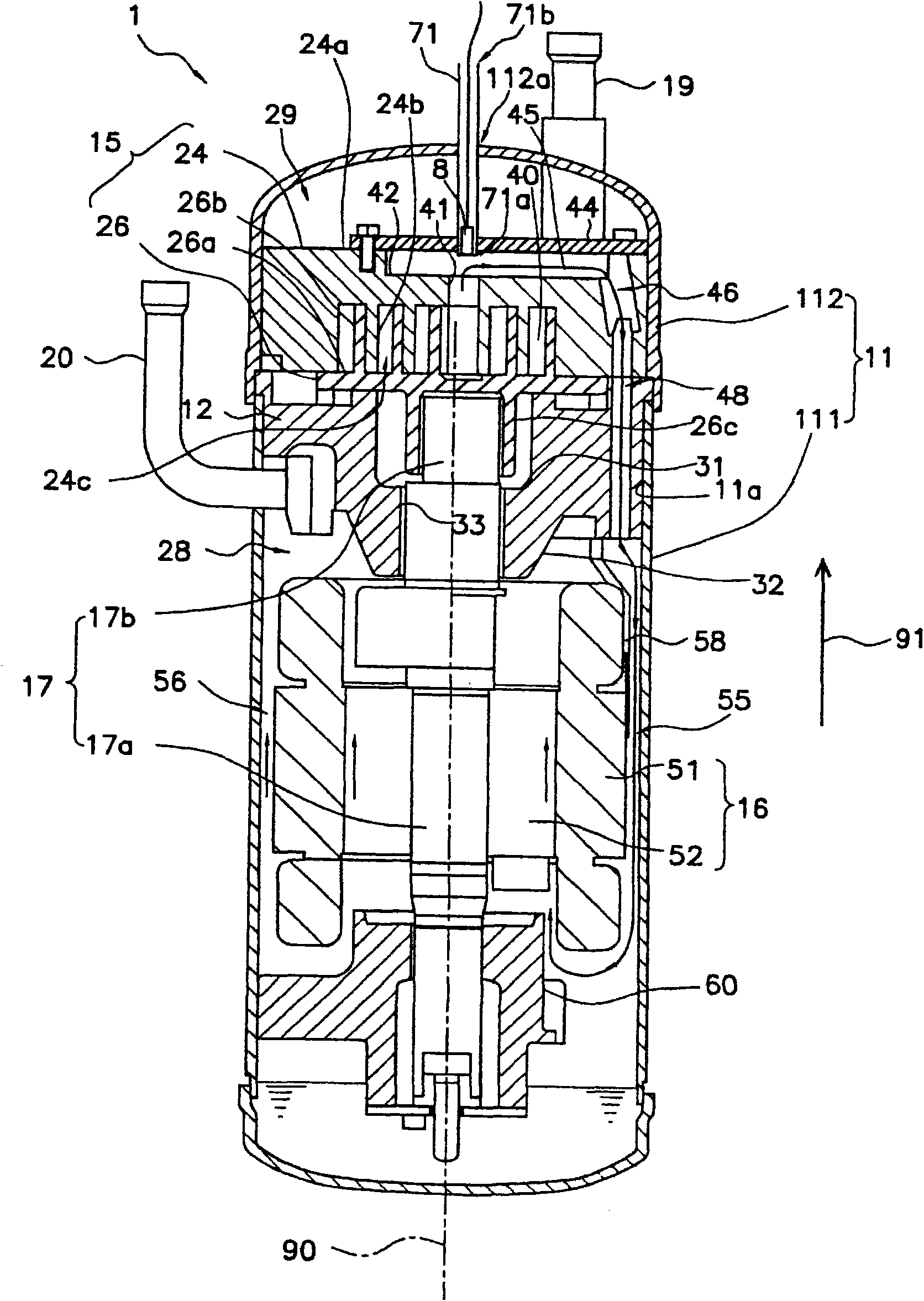

[0078] figure 1 It is a conceptual diagram of the scroll compressor 1 which concerns on 1st Embodiment of this invention. exist figure 1 The direction 91 is shown in , and hereinafter, the front end side of the arrow of the direction 91 is called "upper side", and the opposite side is called "lower side".

[0079] The scroll compressor 1 includes a casing 11 , a stationary member 12 , a compression mechanism 15 , a motor 16 , a crankshaft 17 , a suction pipe 19 , a discharge pipe 20 , and a bearing 60 .

[0080] The housing 11 has a cylinder 111 and a cover 112 extending in the direction 91 . The cover 112 covers the upper end of the cylinder 111 . A fixed member 12 , a compression mechanism 15 , an electric motor 16 , a crankshaft 17 , and a bearing 60 are housed in the housing 11 .

[0081] The motor 16 has a stator 51 and a rotor 52 . The stator 51 is annular and fixed to the inner wall 11 a of the housing 11 . The r...

no. 2 Embodiment approach

[0129] (Structure of the scroll compressor 201)

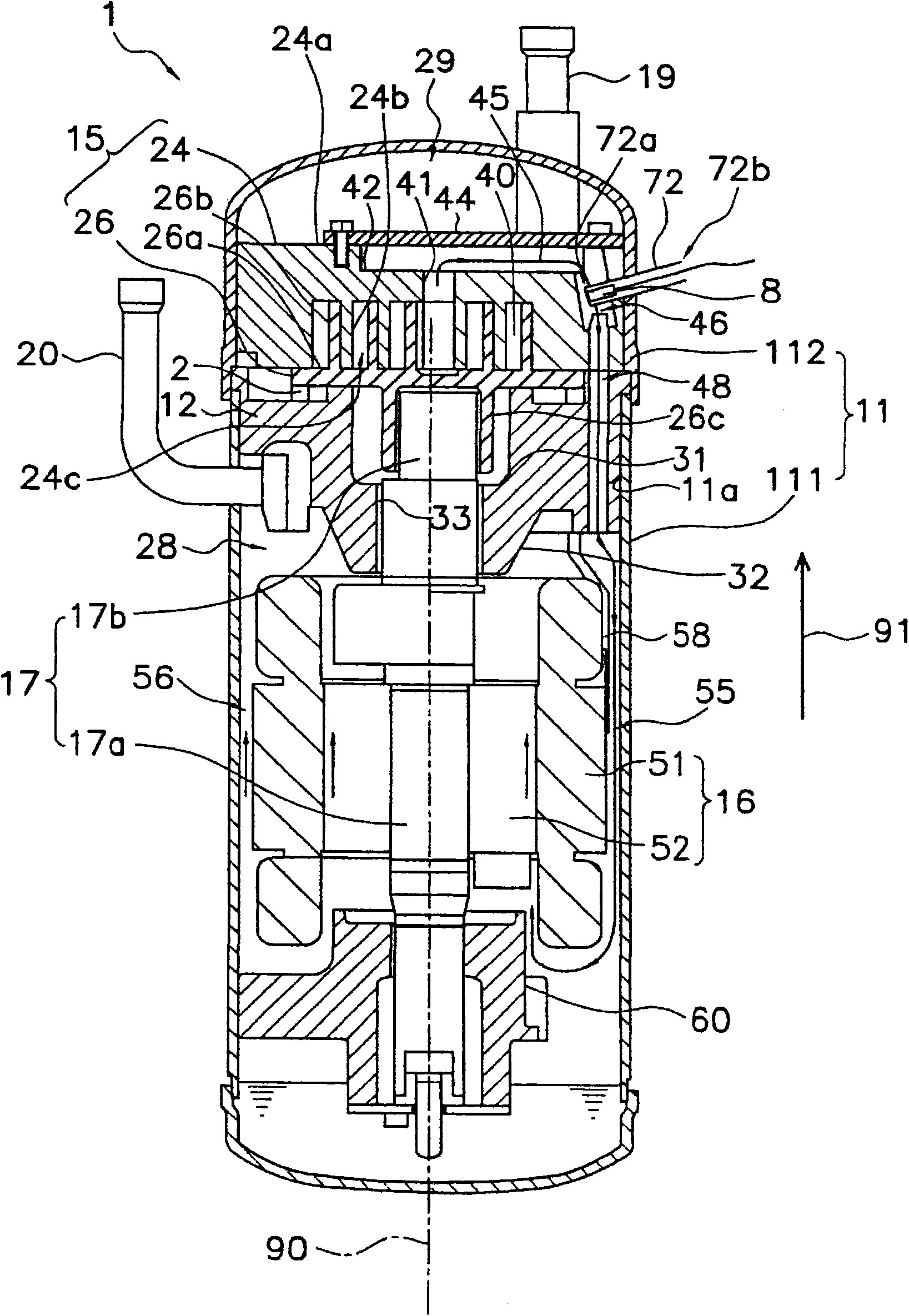

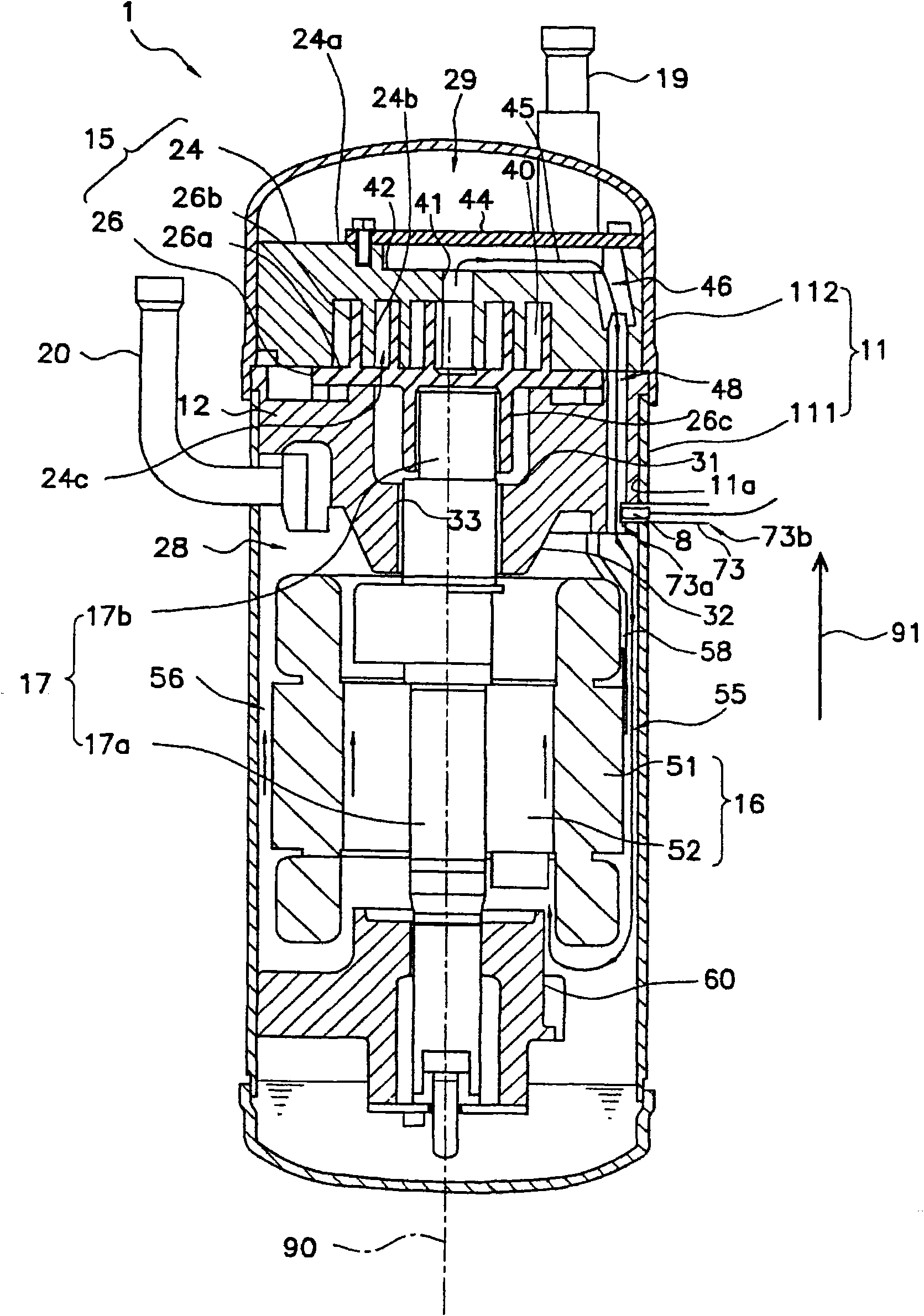

[0130] Figure 6 It is a conceptual diagram of the scroll compressor 201 which concerns on 2nd Embodiment of this invention. Figure 6 The illustrated scroll compressor 201 is constructed substantially the same as figure 1 The scroll compressor 1 shown in common, in Figure 6 in, with figure 1 The same notation as in figure 1 The components shown are the same components.

[0131] which is, Figure 6 The illustrated scroll compressor 201 includes a casing 11 , a stationary member 12 , a compression mechanism 15 , a motor 16 , a crankshaft 17 , a suction pipe 19 , a discharge pipe 20 , a bearing 60 , and a guide plate 58 .

[0132] exist Figure 6 In the fixed member 12 shown, the recessed part 31 and the hole 33 are comprised by the roller bearing which fits in the fixed member 12. As shown in FIG.

[0133] The motor 16 is arranged under the compression mechanism 15 and is a driving source of the compression mechanism 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com