Energy-saving humidifier

A humidifier, wet plate technology, used in spray/jet textile material processing, textiles and papermaking, etc., can solve the problem of reduced moisture regain, easy to be carried to other parts of the equipment in the form of water droplets or water mist, corrosion, etc. problem, to achieve the effect of ensuring the resurgence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

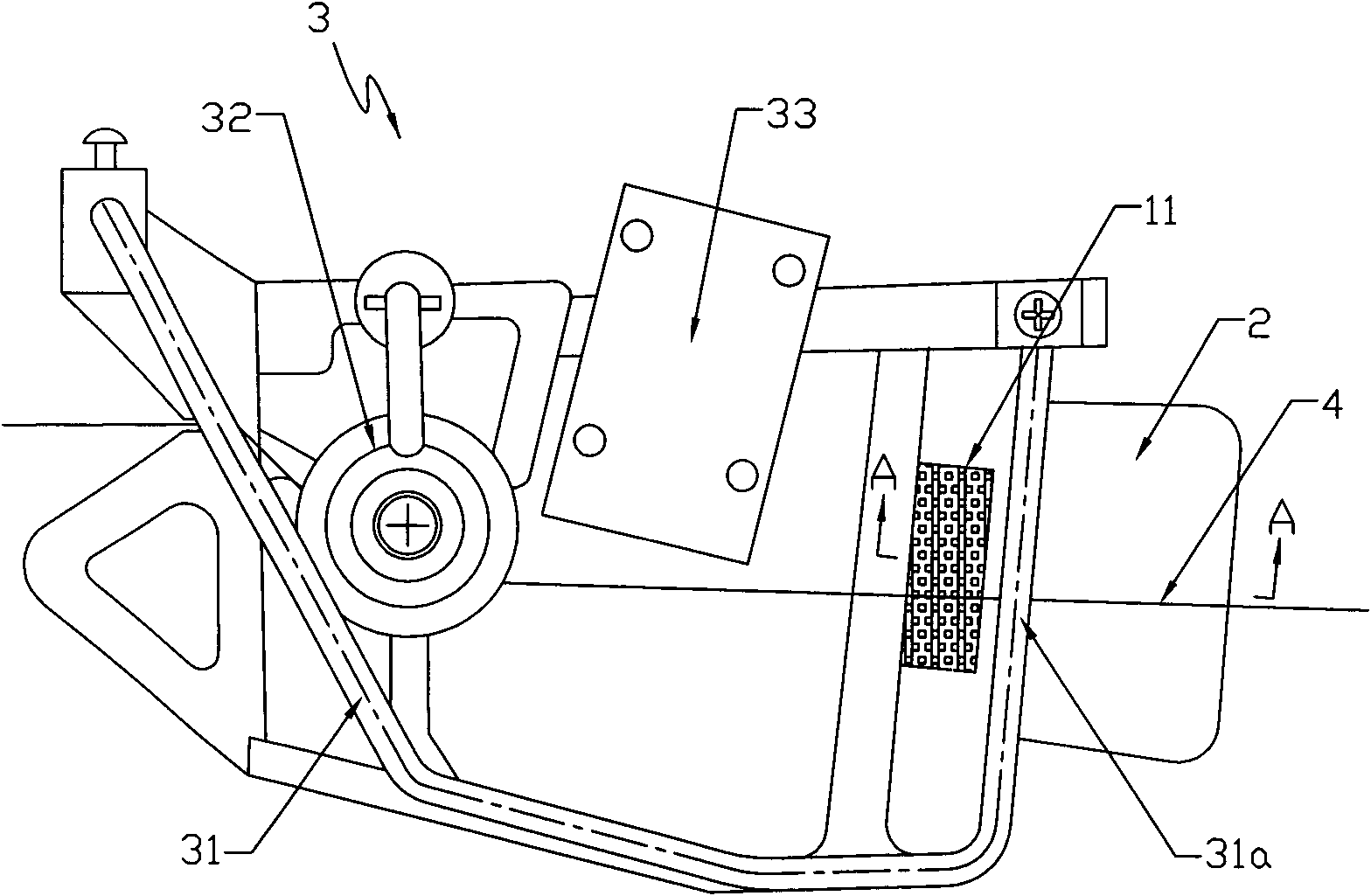

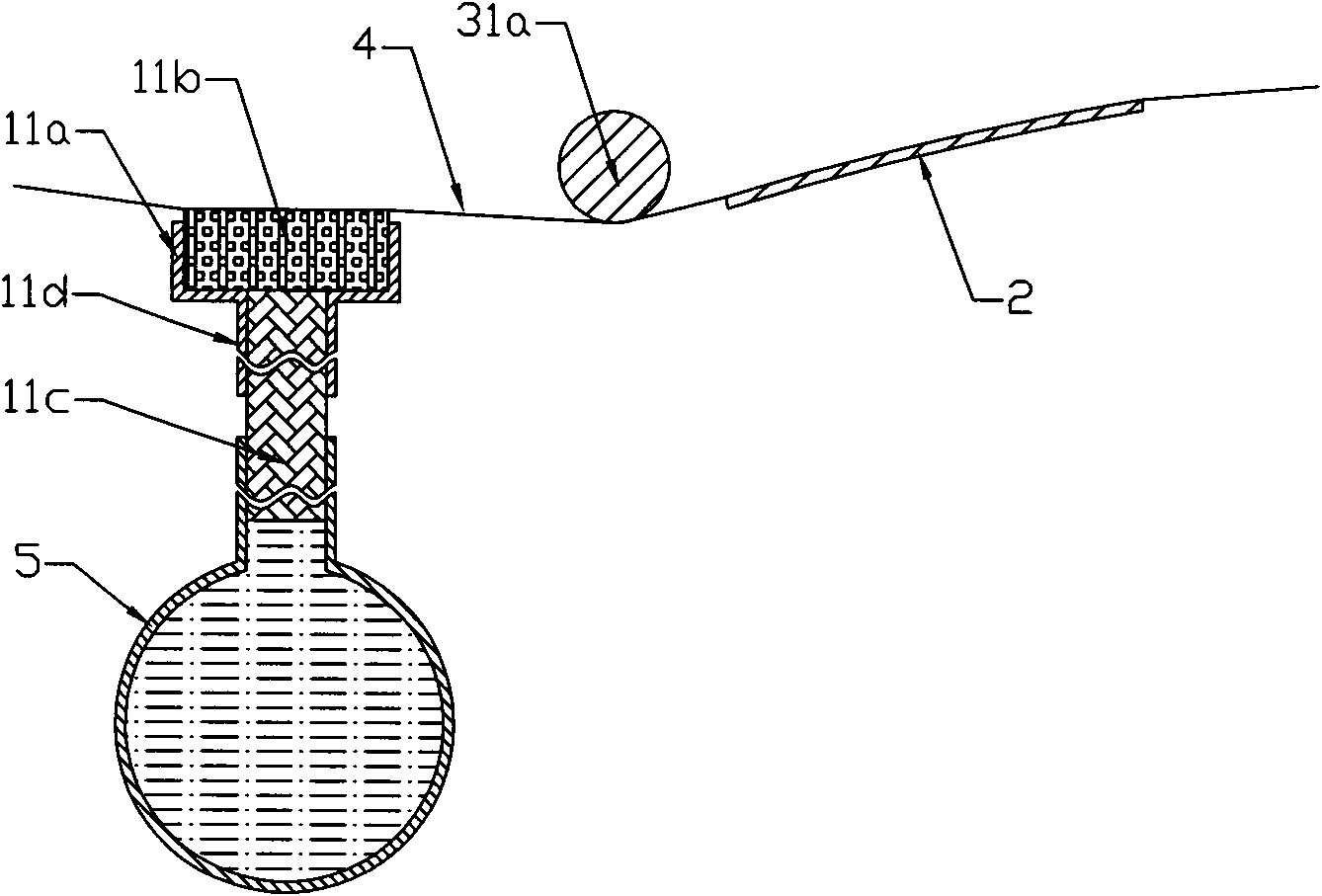

[0029] like Figure 1A , 1B The energy-saving humidifier shown has a water seepage device 11, and a humidifying plate 2 is arranged on the rear side of the water seepage device 1; the water seepage device 11 includes an embedded groove 11a, and a pipe 11d is fixed on the embedded groove 11a. Groove 11a is embedded with seepage material 11b such as felt etc., and this seepage material 11b is connected with water seepage twist 11c (water seepage twist can be made of cotton yarn), and water seepage twist 11c wears in the pipe 11d and leads to water supply pipe 5 so that draw water source.

[0030] The energy-saving humidifier has a large embedded groove and strong water seepage capacity, and is suitable for application on the yarn guide frame 3 with relatively large installation space.

[0031] In this energy-saving humidifier, the yarn 4 is threaded on the yarn guide frame 3 in a conventional manner, and the yarn 4 is sequentially passed through the water seepage device 11 and t...

Embodiment 2

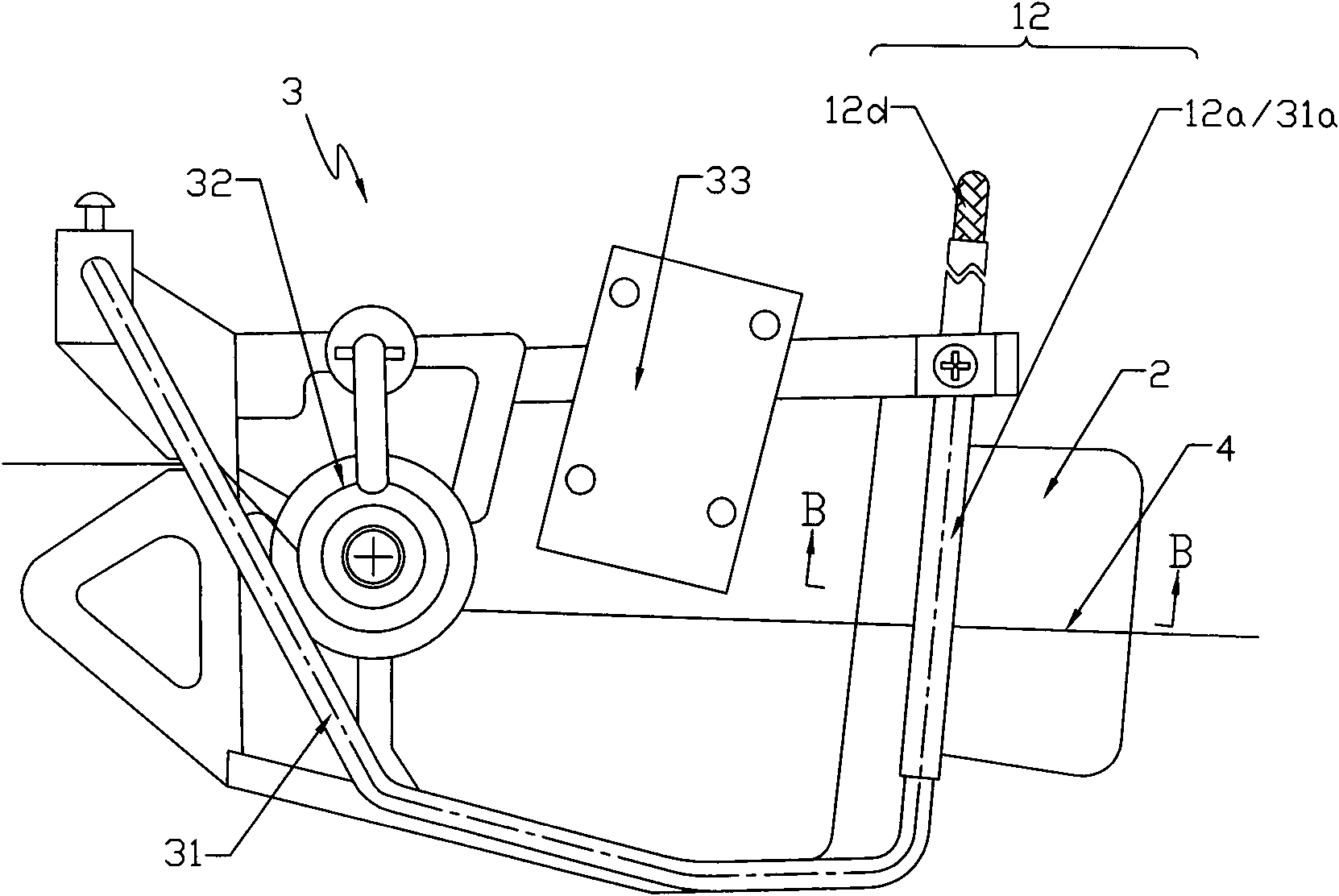

[0033] like Figure 2A , 2B , The energy-saving humidifier shown in 2C has a water seepage device 12, and a humidifying plate 2 is arranged on the rear side of the water seepage device 12; the water seepage device 12 has a yarn passing tube 12a, and a downward The long groove 12b and the water seepage hole 12c connecting the long groove 12b and the inner cavity of the yarn passing tube 12a are filled with water seepage twist 12d in the yarn passing tube 12a.

[0034] In this energy-saving humidifier, the yarn passing tube 12a is used as a part of the yarn passing rod 31 to replace the yarn passing part 31a. Since the yarn passing tube 12a is small in size and can be used as a part of the yarn passing rod 31, it can be applied to any type of yarn guide on the shelf.

[0035] In this energy-saving humidifier, the yarn 4 passes through the yarn tube 12a and the humidifying plate 2 in turn. When working, the water seepage twist 12d is led to the water supply pipe (not shown in t...

Embodiment 3

[0037] like Figure 3A , 3B The energy-saving humidifier shown in , 3C, and 3D has a water seepage device 13, and a humidifying plate 2 is arranged on the rear side of the water seepage device 13; 13a is provided with an upward long groove 13c and a water seepage hole 13d connecting the long groove 13c and the inner cavity of the yarn passing tube 13a; 13e.

[0038] The energy-saving humidifier can be applied to any type of yarn guide frame because the yarn passing tube 13a has a small volume.

[0039] In this energy-saving humidifier, the yarn 4 passes through the yarn tube 13a and the humidifying plate 2 in turn. When working, the water seepage twist 13e is led to the water supply pipe (not shown in the figure) to absorb the water source, and the water seepage twist 13e is absorbed from the water supply pipe. The moisture will be drawn into the yarn passing tube 13a, and the moisture will overflow to the long groove 13c through the water seepage hole 13d, then the yarn 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com