Leak stoppage structure of diaphragm pump head cover body

A head cover body and diaphragm pump technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as loss of product reputation, increase in manufacturing and maintenance costs, and thinning of thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

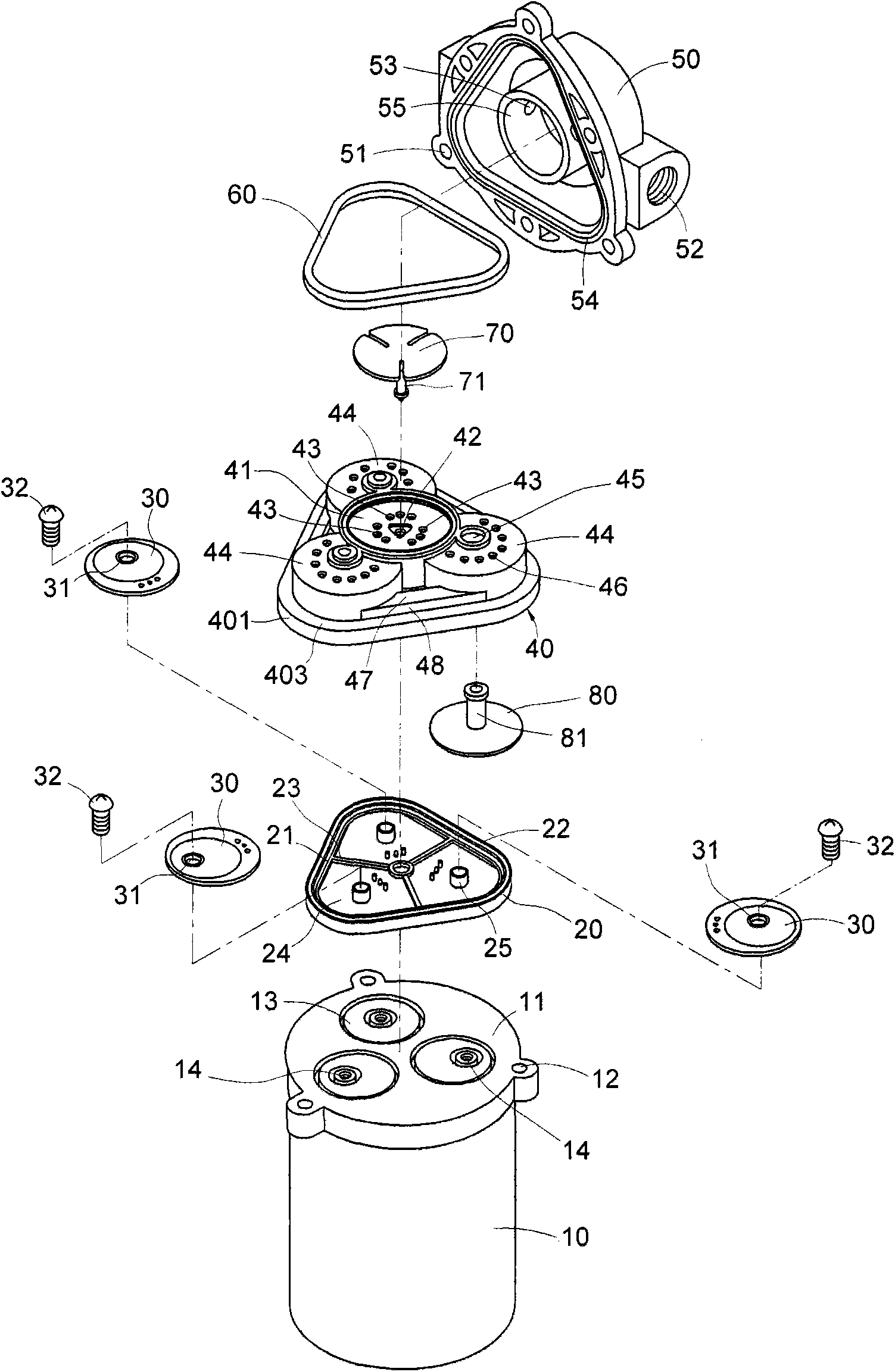

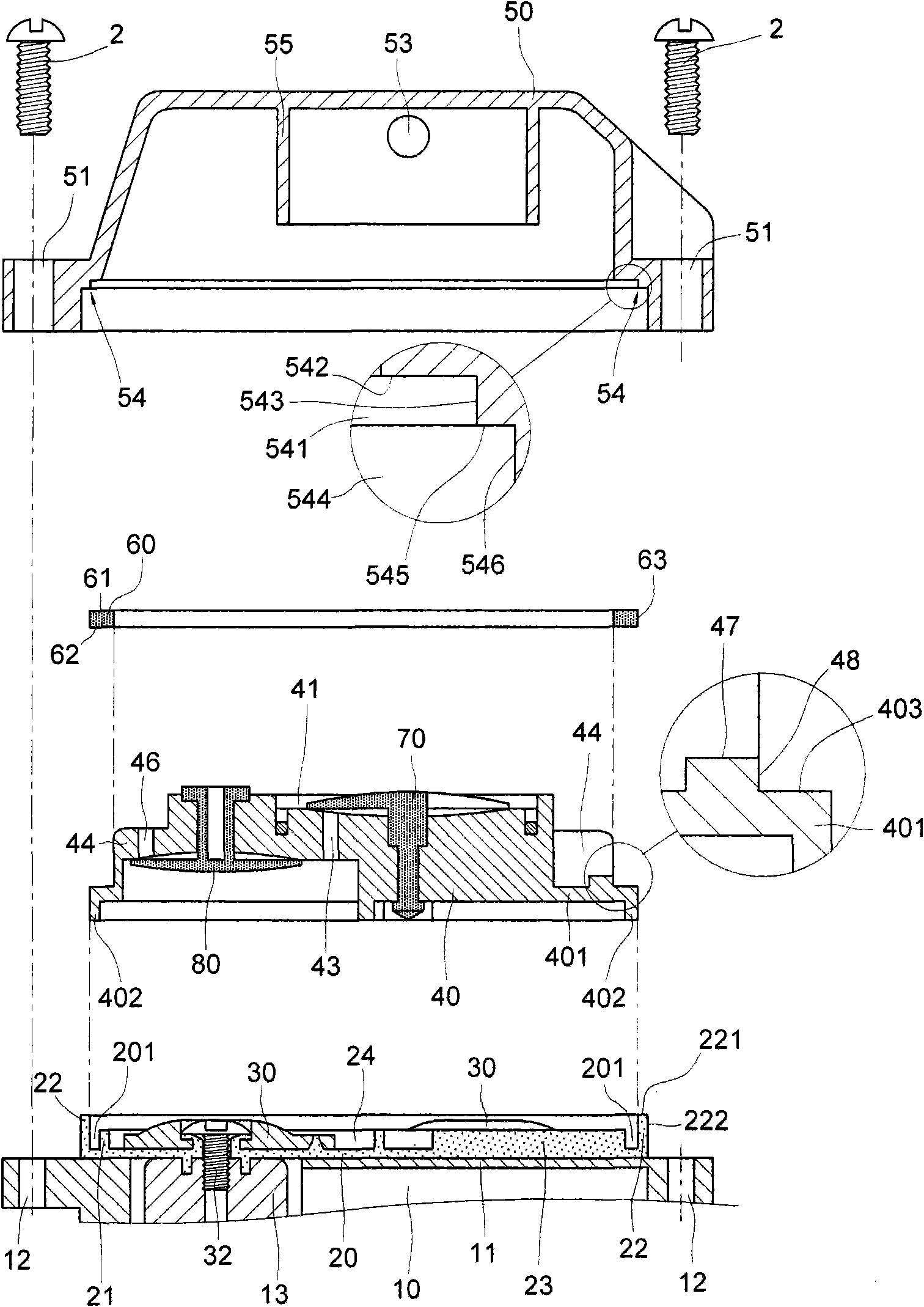

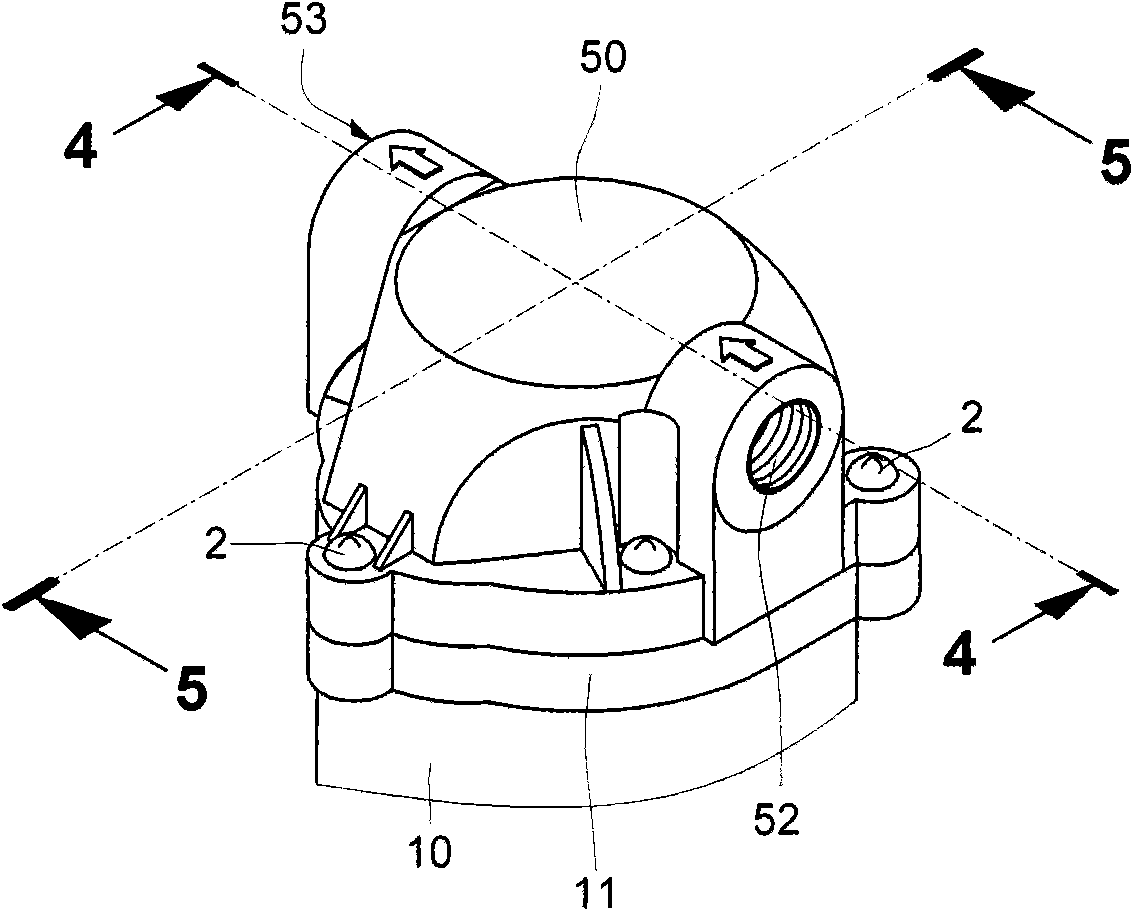

[0079] like Figures 14 to 16 As shown, it is the first embodiment of the leak-proof structure of the pump head cover of the diaphragm pump according to the present invention. Wall 547 (eg Figure 12 ), so that after the water-stop washer 60 is threaded and positioned on the edge top surface 403 of the base 401 of the piston valve body 40, it is tightly plugged into the stepped groove 54 of the pump head cover 50. (like Figure 15 shown), the outer side surface 63 of the water-stop washer 60 will be contacted and squeezed by the inclined wall surface 547 in the lower step groove 541 in the stepped groove 54, and a horizontal level will be generated on the outer side 63 of the water-stop washer 60 immediately. The force Fh (such as Figure 16 In this case, under the blocking action of the outer edge surface 48 of the positioning protruding strip 47 in the piston valve body 40, the water-stop washer 60 will be vertically squeezed and deformed, and the Its interior will synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com