Pneumatic design method for separation type exhaust jet pipe of high bypass ratio engine

A large bypass ratio, aerodynamic design technology, applied in the direction of calculation, special data processing applications, instruments, etc., to achieve the effect of reducing the design cycle and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

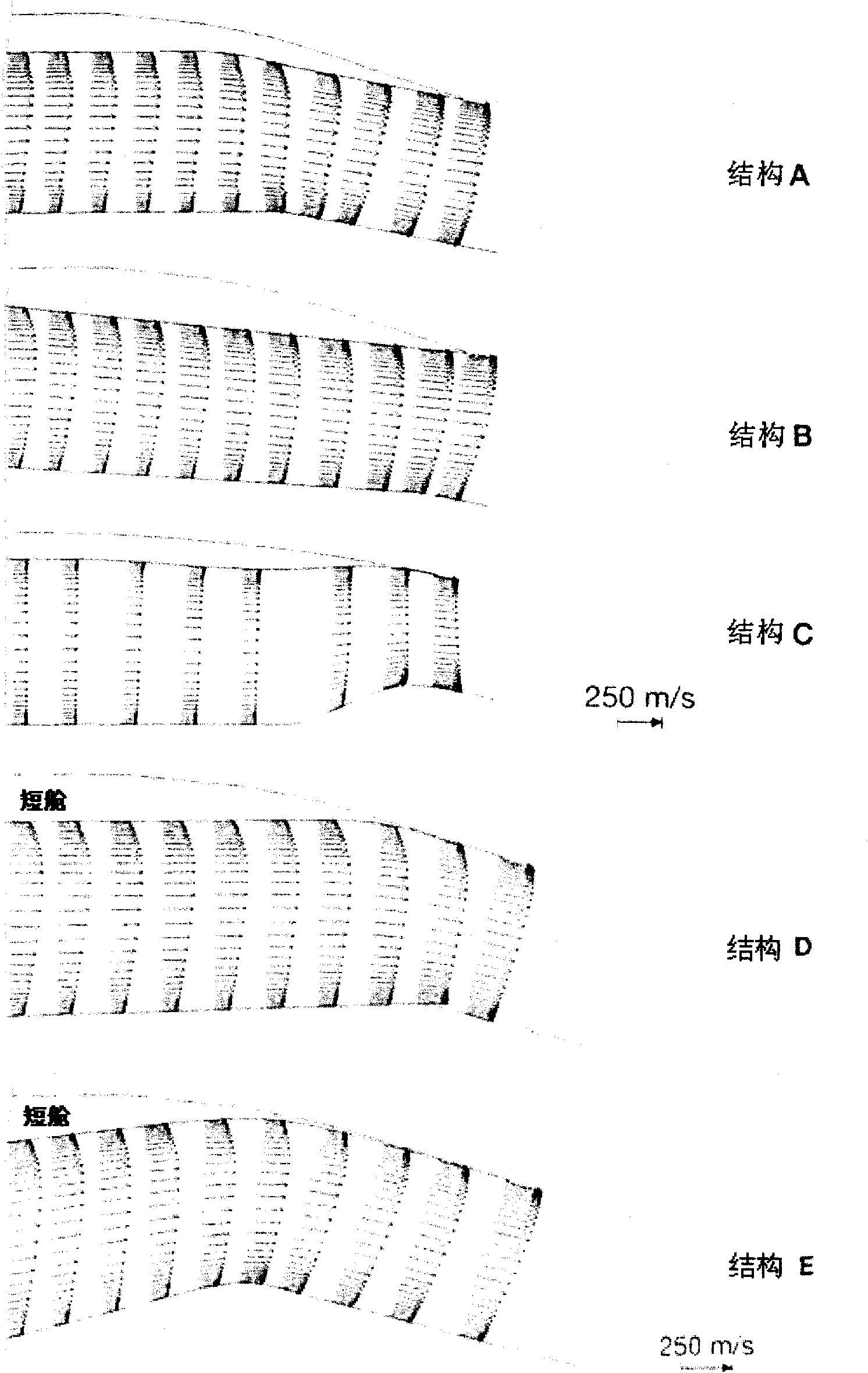

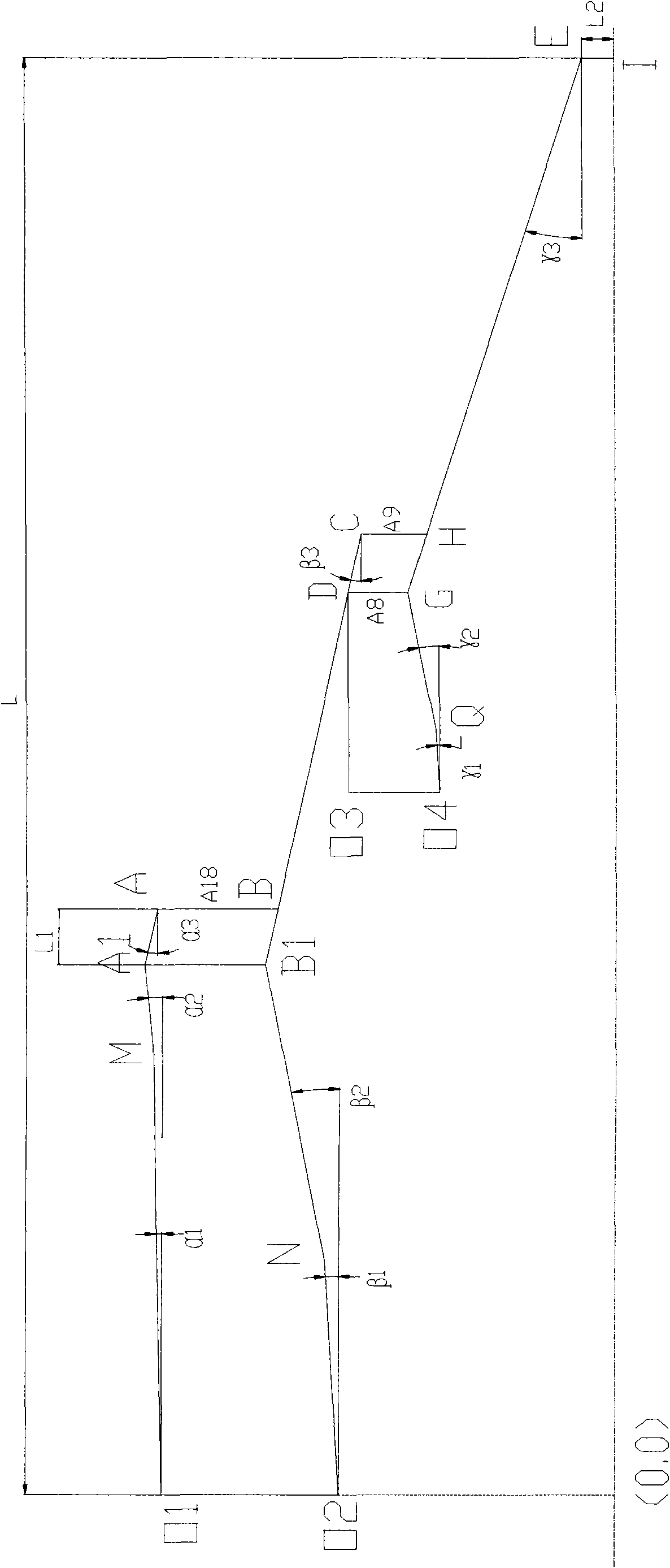

[0018] The following characteristics are adopted in the design of the split exhaust nozzle of the high bypass ratio engine: in order to reduce flight resistance, the outer nozzle is designed as an external expansion nozzle, and the flow cross-sectional area is in a convergent form; the inner nozzle is designed as The mixed expansion nozzle adopts the form of convergence-expansion in the flow cross-sectional area. The aerodynamic shape of the nozzle is formed in the form of straight line segments, and the straight line segments are connected by arcs.

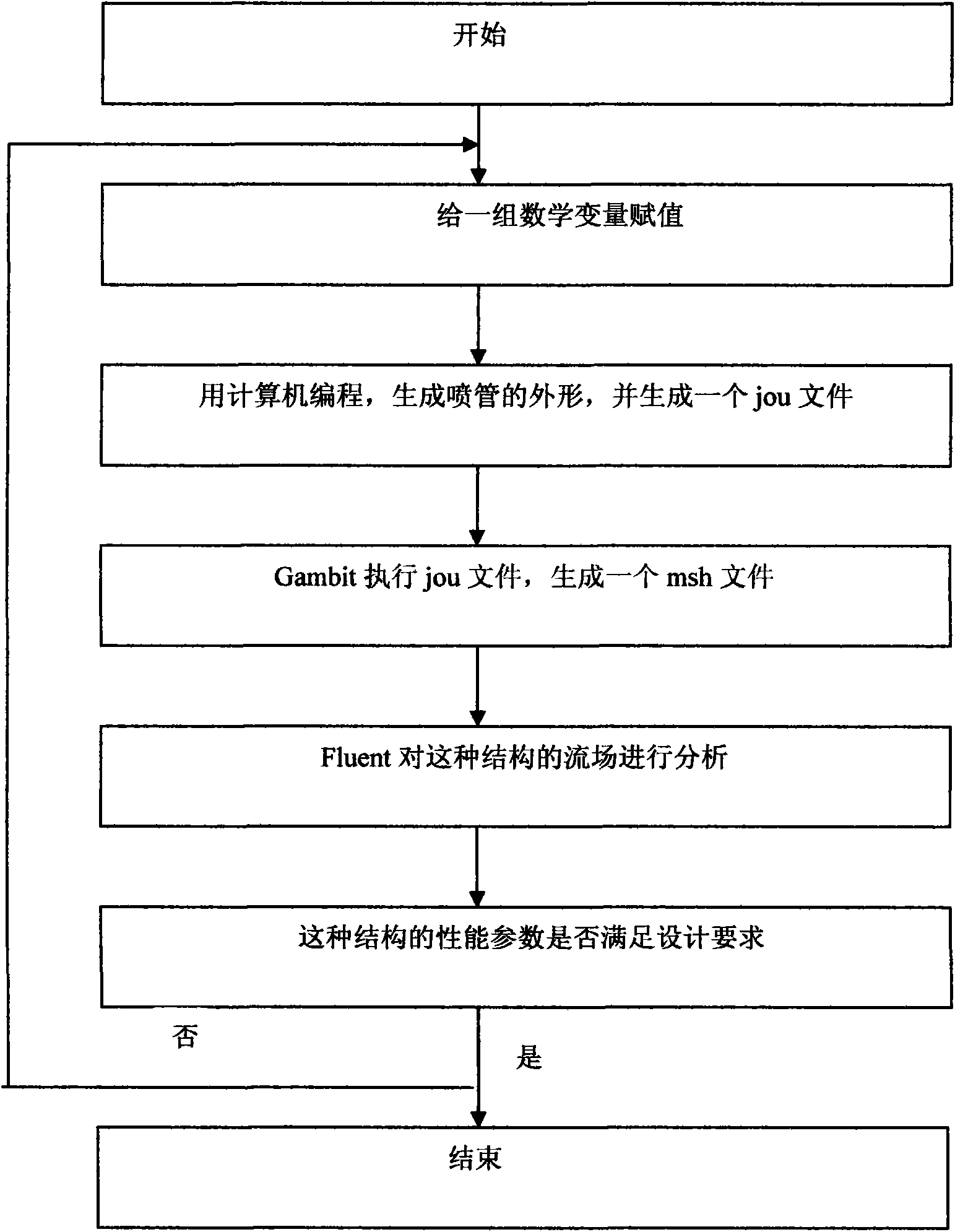

[0019] The aerodynamic design of the split exhaust nozzle of a large bypass ratio engine is carried out according to the following steps——

[0020] The specific steps are:

[0021] Step 1 of defining the initial parameters of the aerodynamic design of the nozzle, including the outer outlet inclination angle of the external nozzle α 3 , the inclination angle β of the back cone of the culvert nozzle 3 , the outer vertex coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com