Interior panelling comprising a built-in airbag cover for a motor vehicle, and a method for producing same

A technology of inner space and airbags, which is applied to vehicle components, vehicle safety arrangements, pedestrian/passenger safety arrangements, etc., can solve the problems of injury to car occupants, separation of debris, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

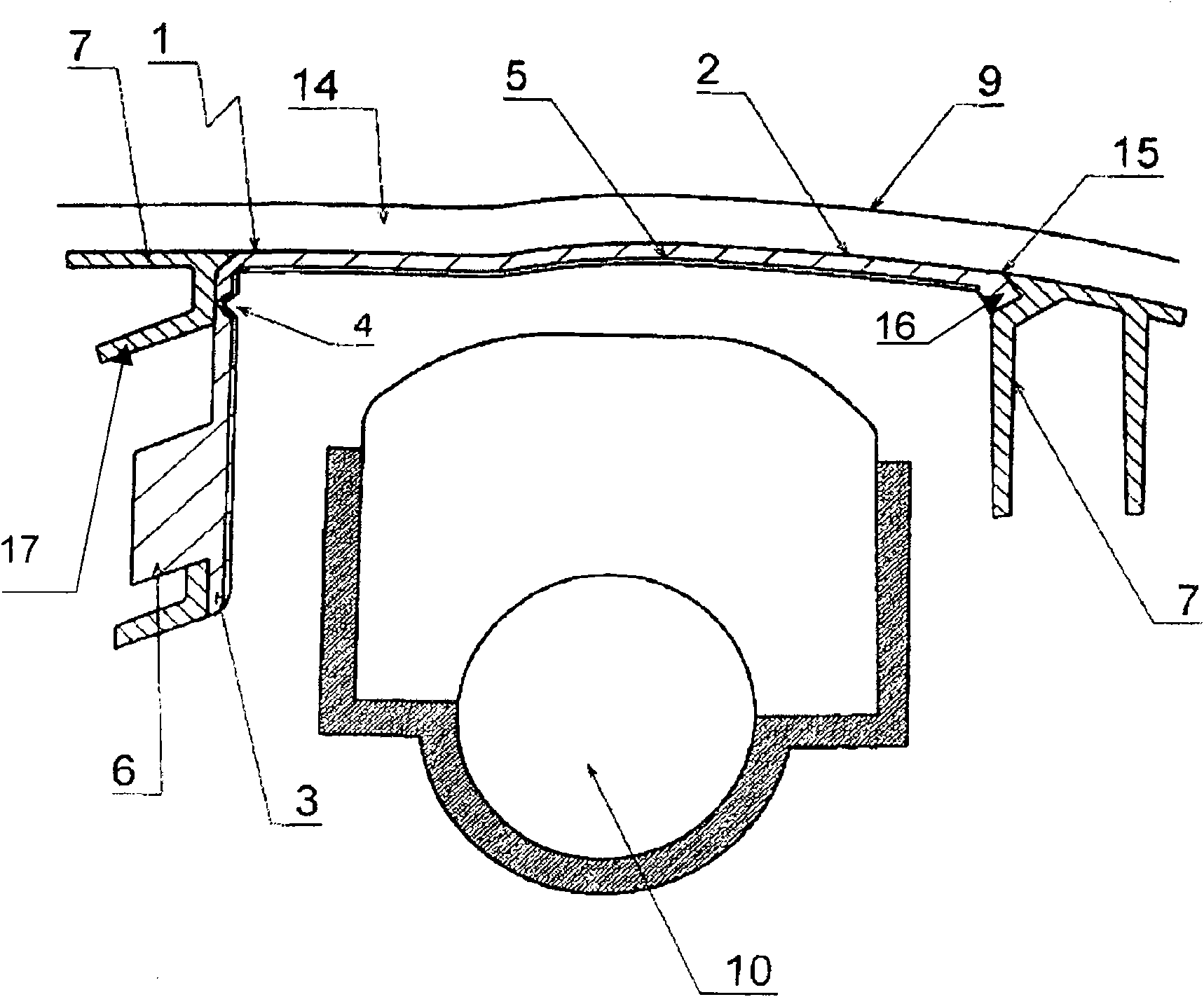

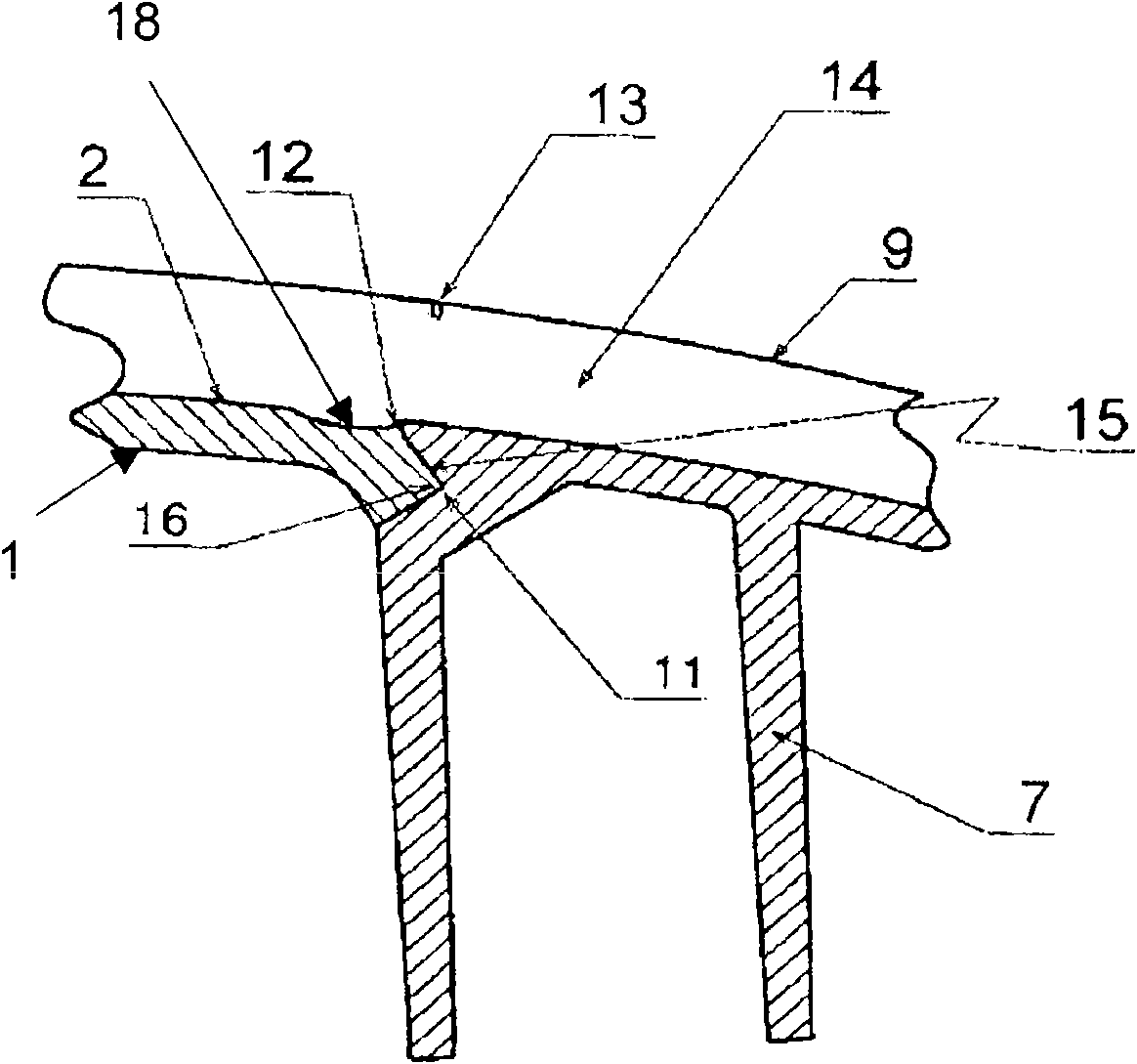

[0037] figure 1 Shows a cross-sectional view of the inner space liner with integrated airbag module. In this figure, an airbag cover 1 with a cover 2 and a hinge 3 and a debris guard 5 can be seen, the airbag cover being fitted in a corresponding hole in the instrument panel. The hinge part 3 has a set breaking notch 4 and an anchor forming part 6.

[0038] The airbag cover 1 is accurately matched and inserted into the instrument panel frame 7, wherein the contour geometry 15 of the cover 2 has a molded part protrusion 16, which is embedded in a corresponding hollow in the area of the opening of the instrument panel frame 7 Profile 11. The opening resistance of the cover 2 is controlled by the contour geometry 15 and adapted to actual requirements. The instrument panel frame 7 with the integrated airbag cover 1 is covered with a foam layer 14 and a molded shell 9, wherein the molded shell 9 constitutes the visible side of the instrument panel.

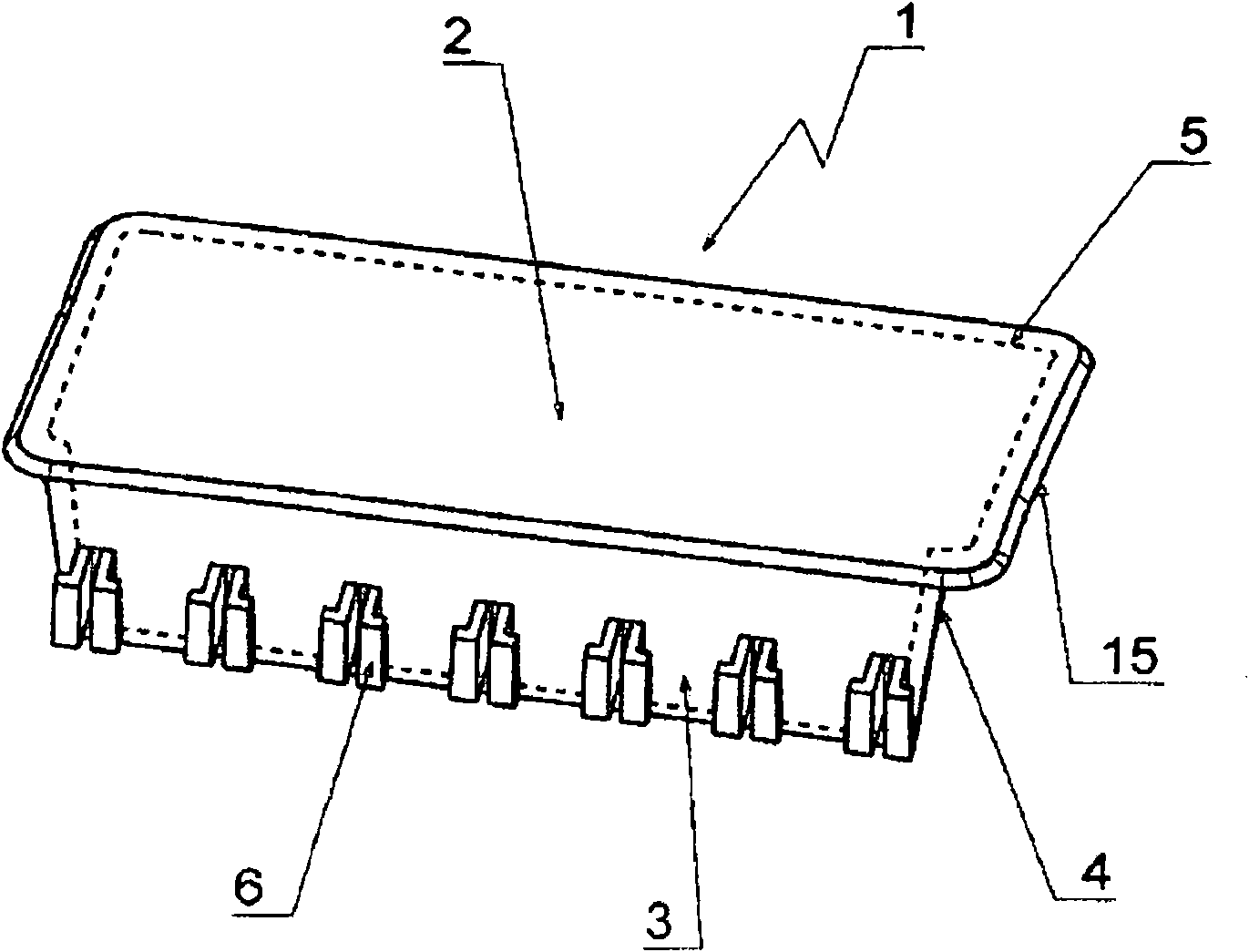

[0039] figure 2 A three-dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com