Coal gas small furnace of energy-saving durable type fuel generation furnace for glass tank furnace

A kind of furnace gas, durable technology, applied in glass production, glass furnace equipment, glass manufacturing equipment and other directions, can solve the problems of low service life, waste of energy, easy to burn out pre-combustion chamber wall, etc., to achieve long service life, Good energy-saving effect, beneficial to the effect of downward heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

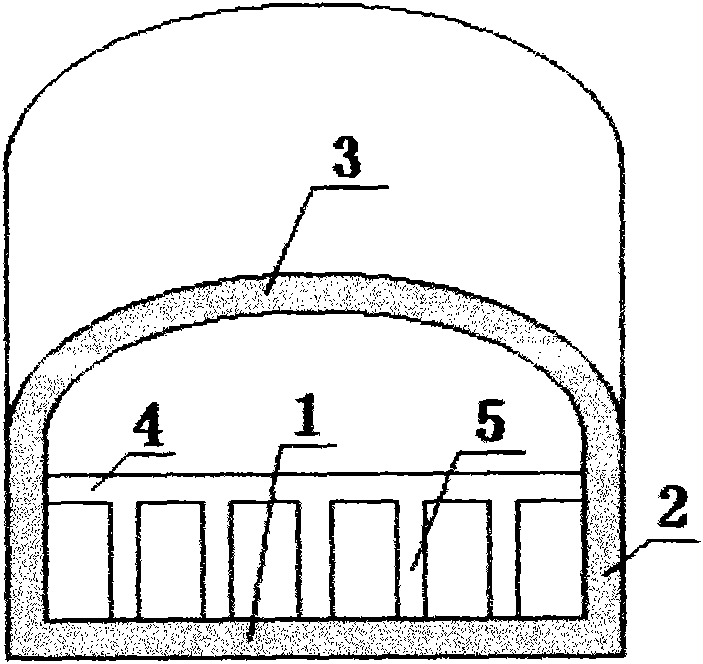

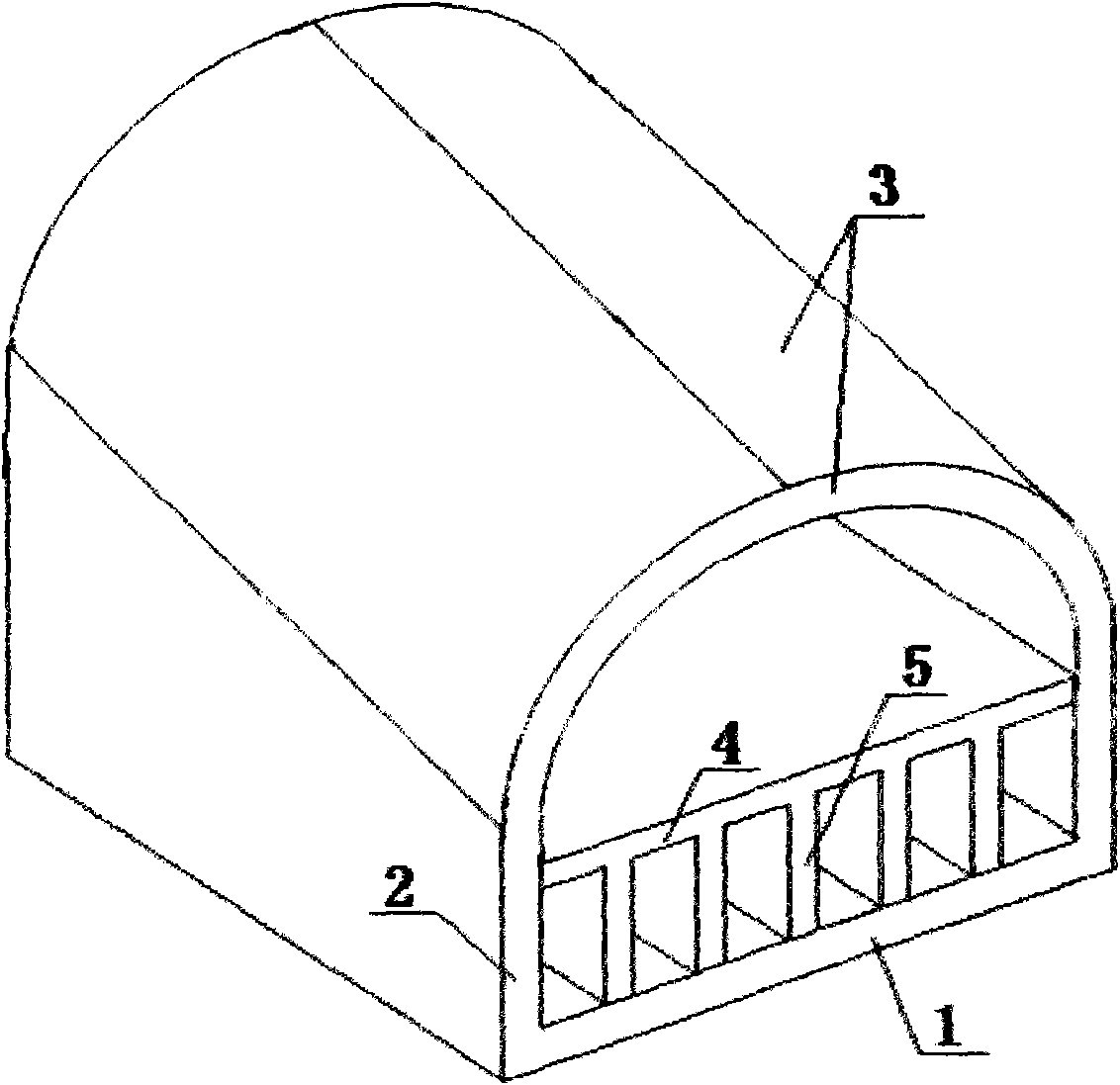

[0022] Embodiment one, such as figure 1 , 2 As shown in and 7, the energy-saving and durable gas-fired small furnace for the glass pool furnace of the present invention includes a bell-shaped longitudinal channel with a small front and a large rear that is composed of a bottom plate 1, two side walls 2 and an arched top wall 3, and the middle part of the longitudinal channel is An arched tongue 4 extending from the rear end to the front end is formed connecting the two side walls 2 , and the lower longitudinal channel separated by the tongue 4 is composed of six laterally juxtaposed sub-channels separated by the vertical partition 5 . The distance between the tongue 4 and the front end of the vertical partition 5 and the front end of the longitudinal channel is 0-800 mm. The top wall 3 or the top wall 3 and the tongue 4 are inclined downward from back to front. The entrance between the tongue 4 at the rear end of the longitudinal channel and the top wall 3 communicates with ...

Embodiment 2

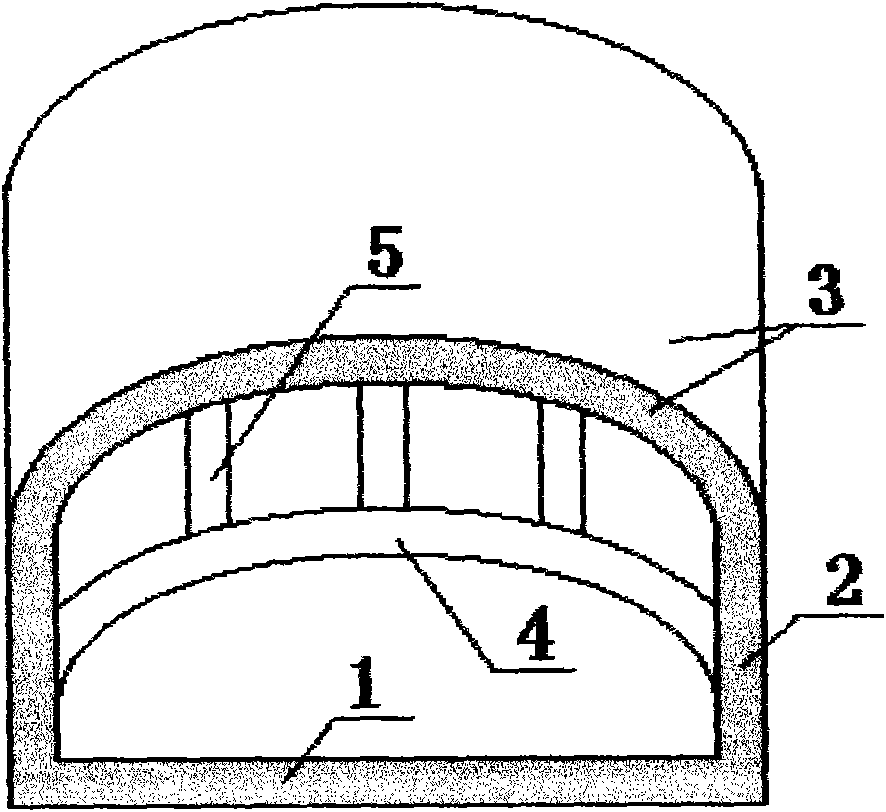

[0023] Embodiment two, such as image 3 and 7 As shown in the present invention, the energy-saving and durable generator-fired small gas furnace for glass pool furnaces of the present invention comprises a trumpet-shaped longitudinal channel with a small front and a large rear formed by a bottom plate 1, two side walls 2 and an arched top wall 3. The middle part of the longitudinal channel is formed with a The flat plate-shaped tongue 4 extending from the rear end to the front end is connected to the two side walls 2, and the upper longitudinal channel separated by the tongue 4 is composed of four horizontally parallel sub-channels separated by the vertical partition wall 5 . The distance between the tongue 4 and the front end of the vertical partition 5 and the front end of the longitudinal channel is 0-800 mm. The top wall 3 or the top wall 3 and the tongue 4 are inclined downward from back to front. The entrance between the tongue 4 at the rear end of the longitudinal cha...

Embodiment 3

[0024] Embodiment three, such as Figure 4 and 7 As shown in the present invention, the energy-saving and durable generator-fired small gas furnace for glass pool furnaces of the present invention comprises a trumpet-shaped longitudinal channel with a small front and a large rear formed by a bottom plate 1, two side walls 2 and an arched top wall 3. The middle part of the longitudinal channel is formed with a The arched tongue 4 extending from the rear end to the front end connecting the two side walls 2, the upper and lower longitudinal channels separated by the tongue 4 are composed of four horizontally parallel sub-channels separated by the vertical partition walls 5 opposite up and down. The distance between the tongue 4 and the front end of the vertical partition 5 and the front end of the longitudinal channel is 0-800 mm. The top wall 3 or the top wall 3 and the tongue 4 are inclined downward from back to front. The entrance between the tongue 4 at the rear end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com