Heat treatment equipment for stainless steel pipe

A heat treatment equipment, stainless steel technology, applied in heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problems of high explosion-proof safety requirements, troublesome safety and maintenance, increased investment costs and operating costs, etc., to reduce production costs, The effect of preventing explosion and reducing maintenance cost

Inactive Publication Date: 2010-03-31

刘文军

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In order to keep the outer surface of stainless steel pipes bright and free of oxidation after annealing, the hydrogen-nitrogen atmosphere generated by the ammonia decomposition equipment is often used as a protective atmosphere during the heat treatment process to minimize the heat treatment process of oxidation or decarburization, but in the process of use, It is necessary to increase the pressure of the ammonia decomposition gas to meet the needs of the work. Now the hydrogen compressor is commonly used to pressurize it. Because the hydrogen compressor has high requirements for explosion-proof safety, the investment cost and operating cost are increased. In terms of safety and maintenance causing a lot of trouble

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

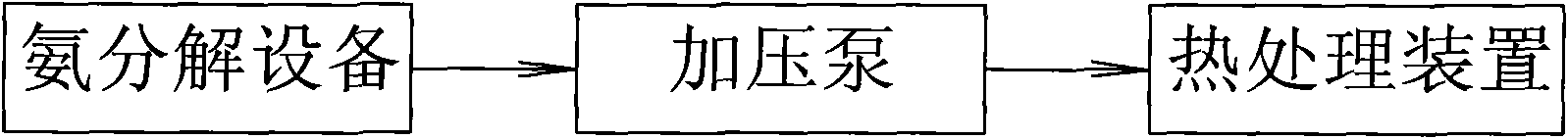

[0007] The invention includes ammonia decomposition equipment and heat treatment device, and a booster pump is arranged between the ammonia decomposition equipment and the heat treatment device.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses heat treatment equipment for a stainless steel pipe and relates to equipment for improving the quality of a metal product. The equipment comprises ammonia decomposing equipmentand a heat treatment device, wherein a pressurizing pump is arranged between the ammonia decomposing equipment and the heat treatment device. Because the pressurizing pump is arranged between the ammonia decomposing equipment and the heat treatment device, an ammonia decomposing gas can be pressurized to a certain value so as to meet the working requirement, and the invention overcomes the defectof explosion hazard of a hydrogen compressor, reduces the maintaining cost and the production cost, prolongs the service life of the heat treatment equipment and has higher practicability.

Description

technical field [0001] The invention relates to a device for improving the quality of metal products, in particular to a heat treatment device for metal products. Background technique [0002] In order to keep the outer surface of the stainless steel pipe bright and free of oxidation after annealing, the hydrogen nitrogen atmosphere generated by the ammonia decomposition equipment is often used as a protective atmosphere during the heat treatment process to minimize the oxidation or decarburization heat treatment process, but in the process of use, It is necessary to increase the pressure of the ammonia decomposition gas to meet the needs of the work. Now the hydrogen compressor is commonly used to pressurize it. Because the hydrogen compressor has high requirements for explosion-proof safety, the investment cost and operating cost are increased. In terms of safety and maintenance caused a lot of trouble. Contents of the invention [0003] The purpose of the present inven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D9/08C21D1/74

Inventor 刘文军

Owner 刘文军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com