Double temperature-sensing power-off circuit protection structure

A technology of inductive power failure and circuit protection, applied in the direction of protection switch operation/release mechanism, thermal switch components, heating/cooling contact switch, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to be able to disclose the purpose, characteristic and effect of the present invention in detail, hereby through the following preferred specific embodiments, in conjunction with the accompanying drawings, the present invention is described in detail as follows:

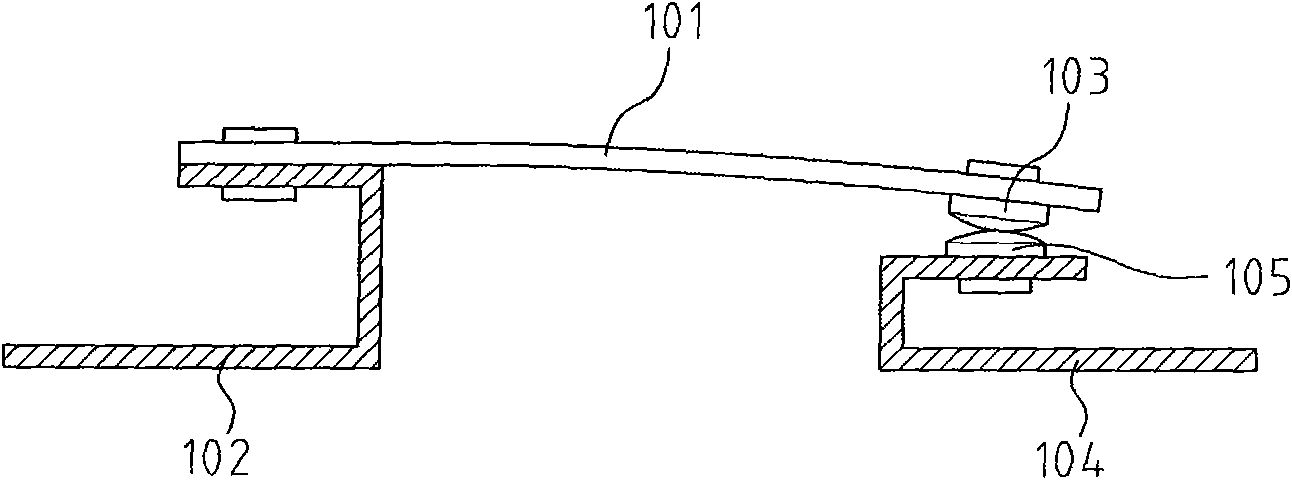

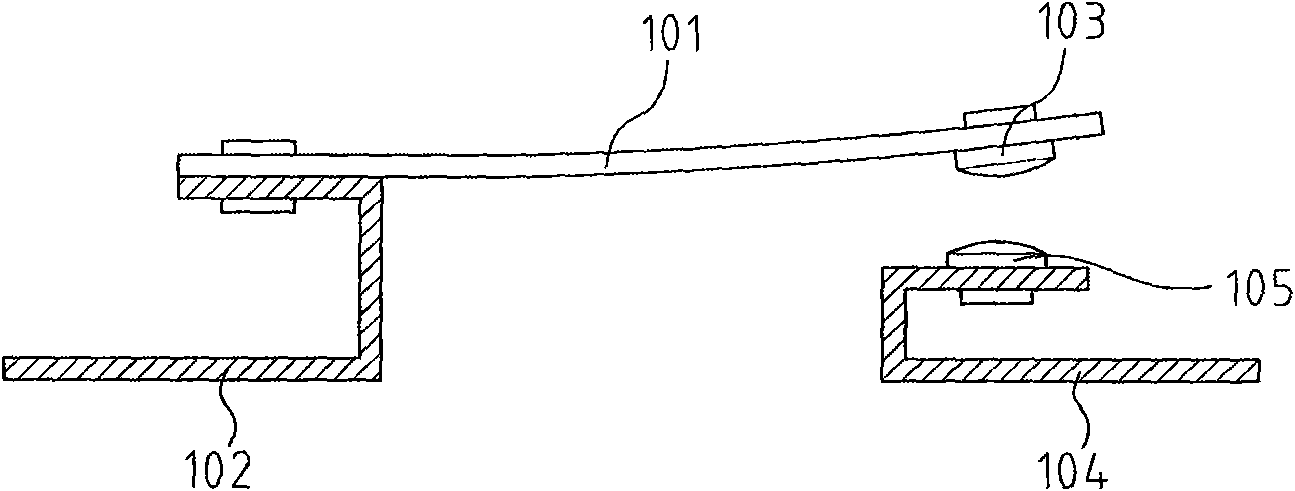

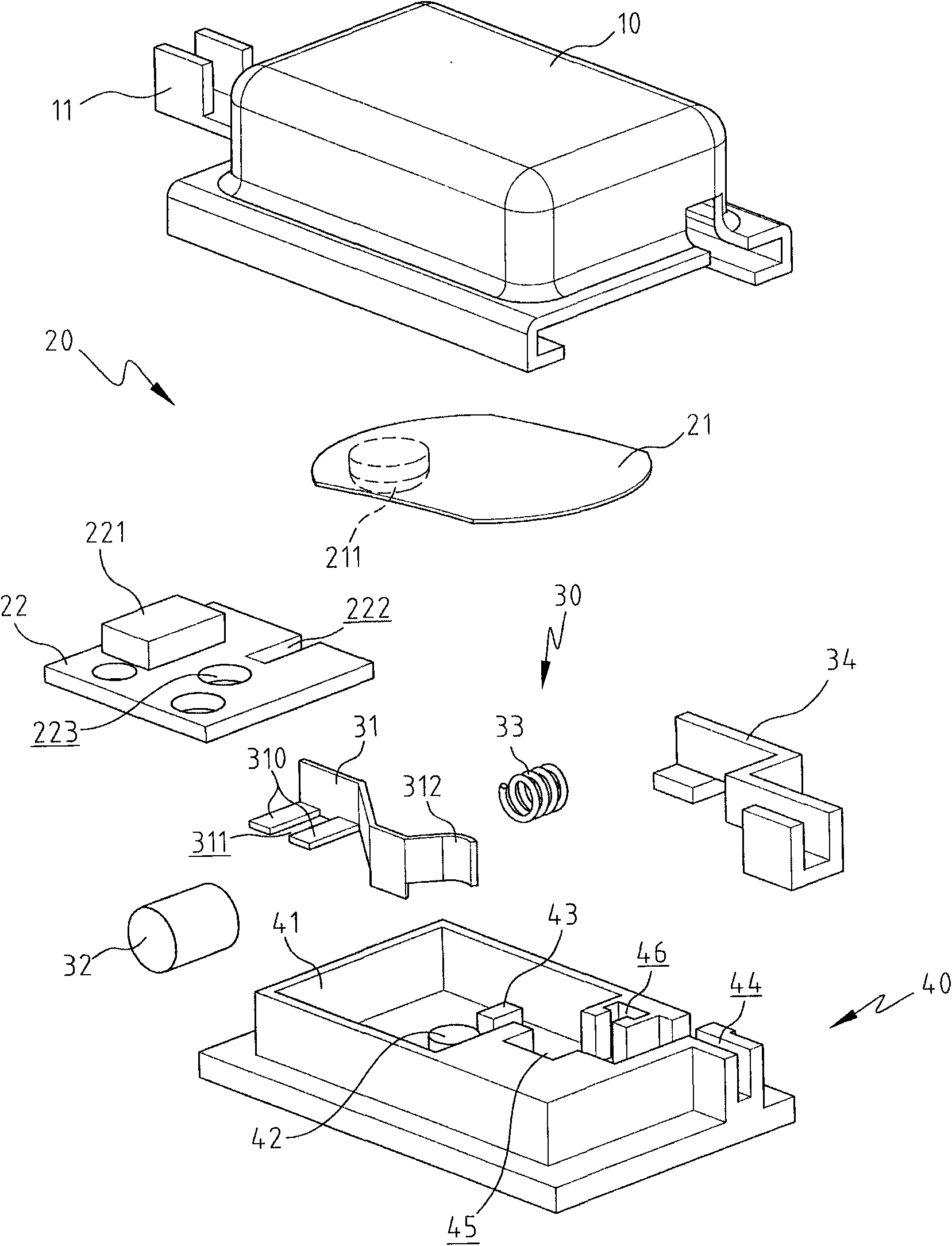

[0059] like Figures 3 to 6 As shown, it is a three-dimensional exploded view, a three-dimensional combined view, a combined cross-sectional view, and a combined cross-sectional view of the embodiment of the present invention, which shows the power-on (ON) schematic diagram of the embodiment of the present invention; a circuit protection structure of a dual temperature induction power-off of the present invention , including a cover body 10, a thermal induction tripping device 20, a thermal fuse device 30, and a seat 40; wherein,

[0060] The cover 10 is a conductor and is connected to a first terminal 11 .

[0061] The thermal induction tripping device 20 includes a contact elastic piece 21 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com