Slag rise preventing method, and punch mold

A punch and scrap technology, applied in the direction of piercing tools, nibbling cutting devices, shearing devices, etc., can solve the problems of blowing to the workpiece, punching waste blowing into the die hole 27, etc., to achieve The effect of preventing rising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

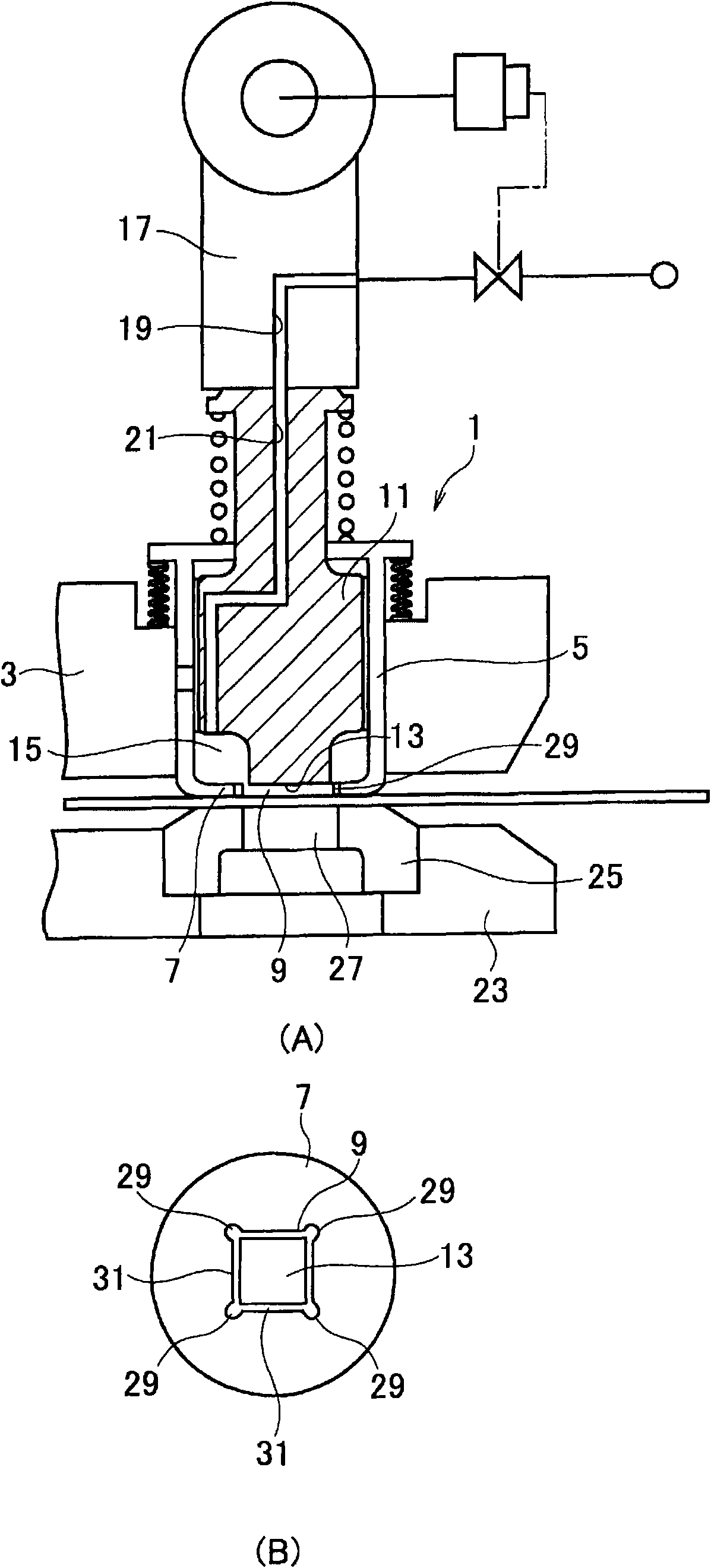

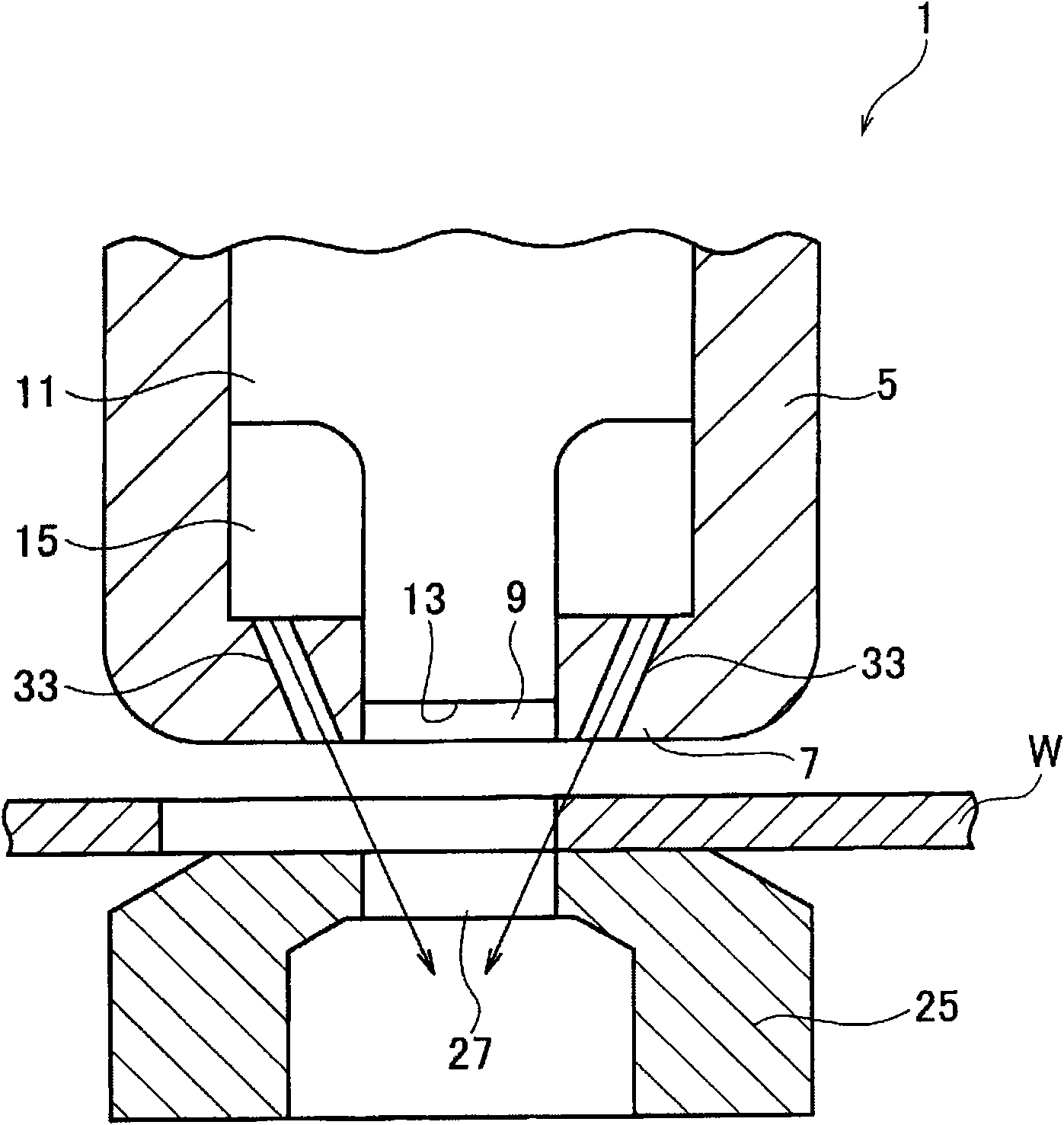

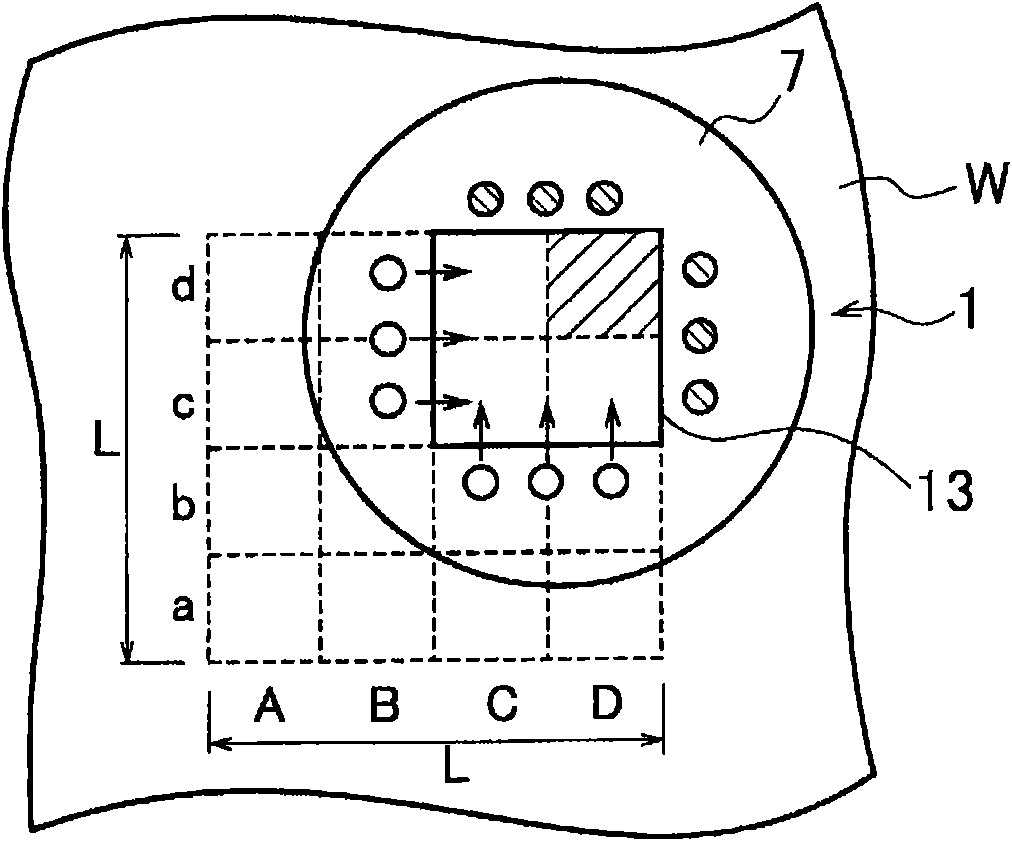

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings, wherein the same symbols are assigned to the structures that can realize the same functions as the above-mentioned conventional structures, and the description is omitted.

[0049] as expressed conceptually and roughly figure 2 According to the structure of the punch and die of the present invention, it is substantially the same as the aforementioned punch 1 and die 25. That is, the punch 1 has a cylindrical punch guide 5 , and the lower portion of the punch guide 5 has a plate pressing portion 7 . Further, a plurality of fluid ejection holes 33 communicating with the annular space 15 are formed around the through hole 9 in the upward direction of the plate pressing portion 7 . The fluid ejection holes 33 are set in a non-communicating state not directly connected to the through hole 9, and point to an obliquely downward direction so as to eject fluid from each fluid ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com