Method for burying drainage-seepage body of reverse filtering pipe in tailing dam

A tailings dam, reverse technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of inability to use the natural slope of dry beaches, failure of seepage prisms, inability to concentrate diversion, etc., to save later The effect of treatment cost, reasonable drainage structure and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

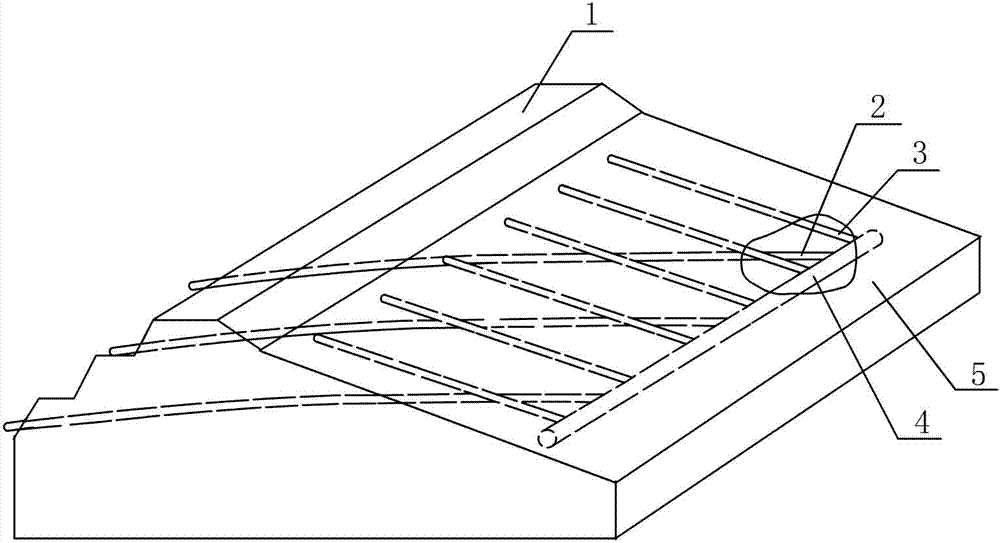

[0013] A method for embedding a seepage body of a reverse filter pipe in a tailings dam, comprising the following steps:

[0014] Aqueduct embedding: A plurality of mutually parallel aqueducts 2 are implanted into the tailings dam body 5 by manual or mechanical piping to form a seepage channel leading from the top of the tailings dam body 5 to the bottom of the dam body. The aqueducts 2 can Use ∮60~∮200 polyethylene plastic pipe;

[0015] Water collection pipe embedding: Excavate the water collection pipe groove along the tailings dam body 5 parallel to the accumulation dam 1, and bury the water collection pipe 4 in sections in the water collection pipe groove. The buried slope of the water collection pipe 4 is greater than 1%, that is The inclination slope of the water collection pipe for every 100 meters is 1 degree, and the inclination slope of the water collection pipe for 200 meters is 2 degrees, and so on. The pipe fittings are plugged in or connected by welding with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com