Method for cleaning metering lines in automatically controlled laundry care devices

A clothing treatment device and automatic control technology, applied in the field of metering pipelines, can solve problems such as operation interference, and achieve the effect of saving water and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

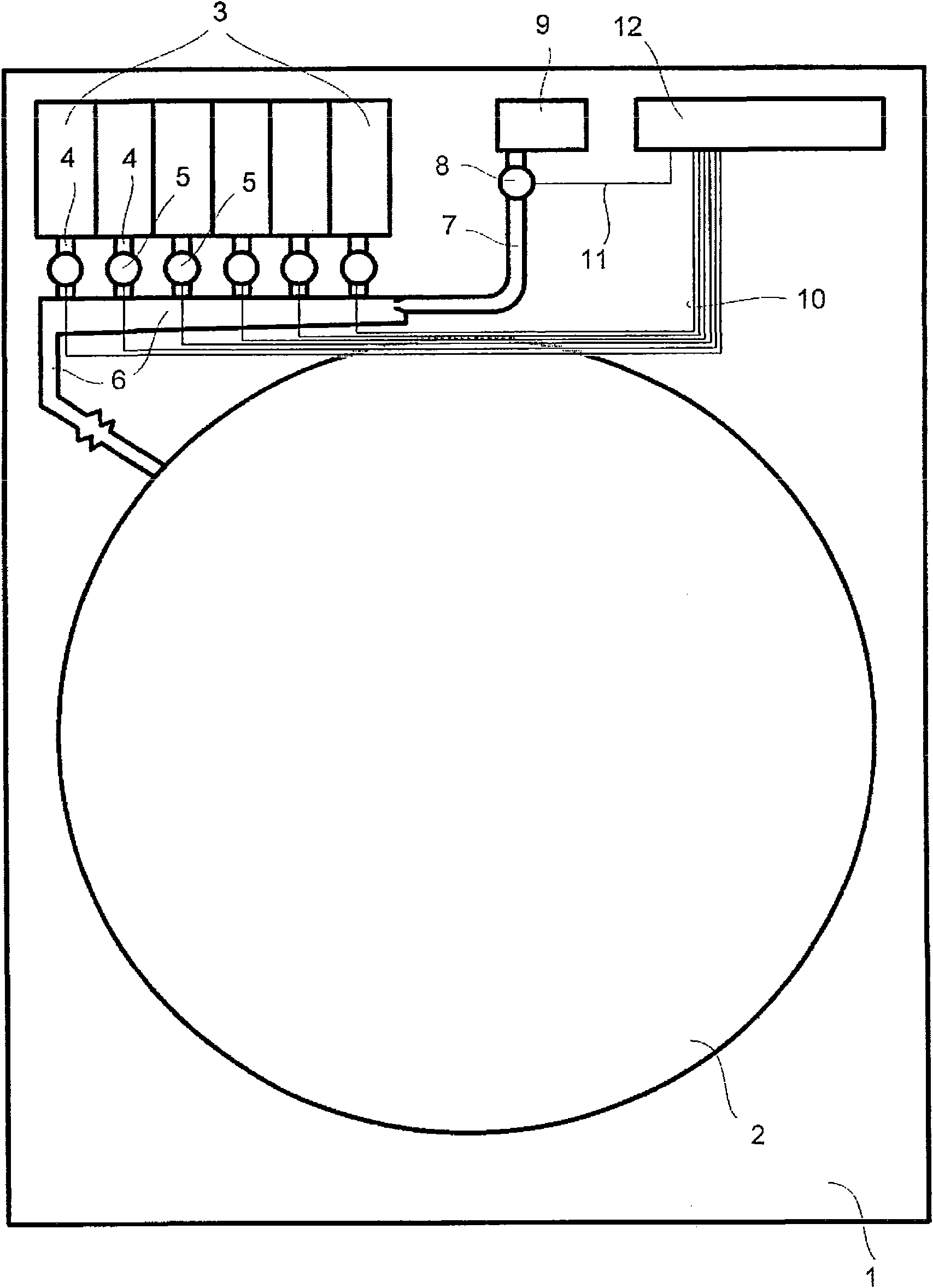

[0015] A laundry treatment chamber 2 is provided in the housing 1, in which laundry treatment chamber can be filled with laundry for treatment of the laundry (not shown). The laundry treatment chamber 2 may be stationary and contain a container that rotates with the laundry or that rotates itself. Inside the housing 1, in addition to parts of its inner chamber, one or more reservoirs 3 are arranged for different liquid or gel type (in any case flowable) laundry treatment agents whose The quantity can be conveyed into a common metering line 6 by means of the outlet line 4 and the metering device 5 . Doses of laundry treatment agent are delivered from the metering line 6 into the laundry treatment chamber. A flushing line 7 is connected to the highest point on the metering line 6 , which can be fed controllably by a flushing agent controller 8 from a flushing agent source 9 . The metering device 5 and the flushing agent controller 8 are supplied with signals by the control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com