Rotary piston machine having an outside gear mechanism

A transmission mechanism and rotary piston technology, applied in rotary piston engines, engine components, machines/engines, etc., can solve problems such as limiting the angle range of the rotor and cylinder liner, and achieve cost-effective, high-precision and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

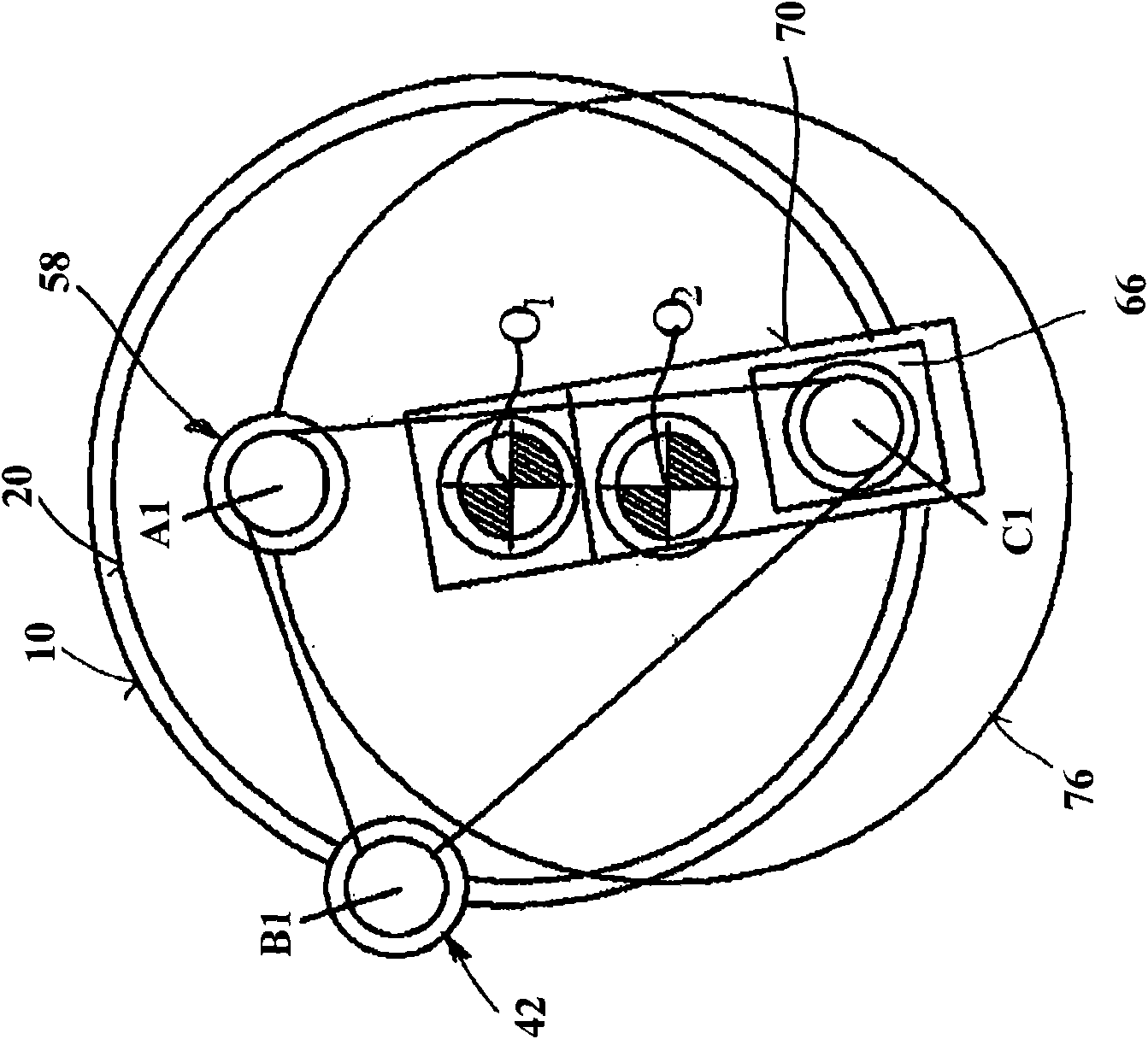

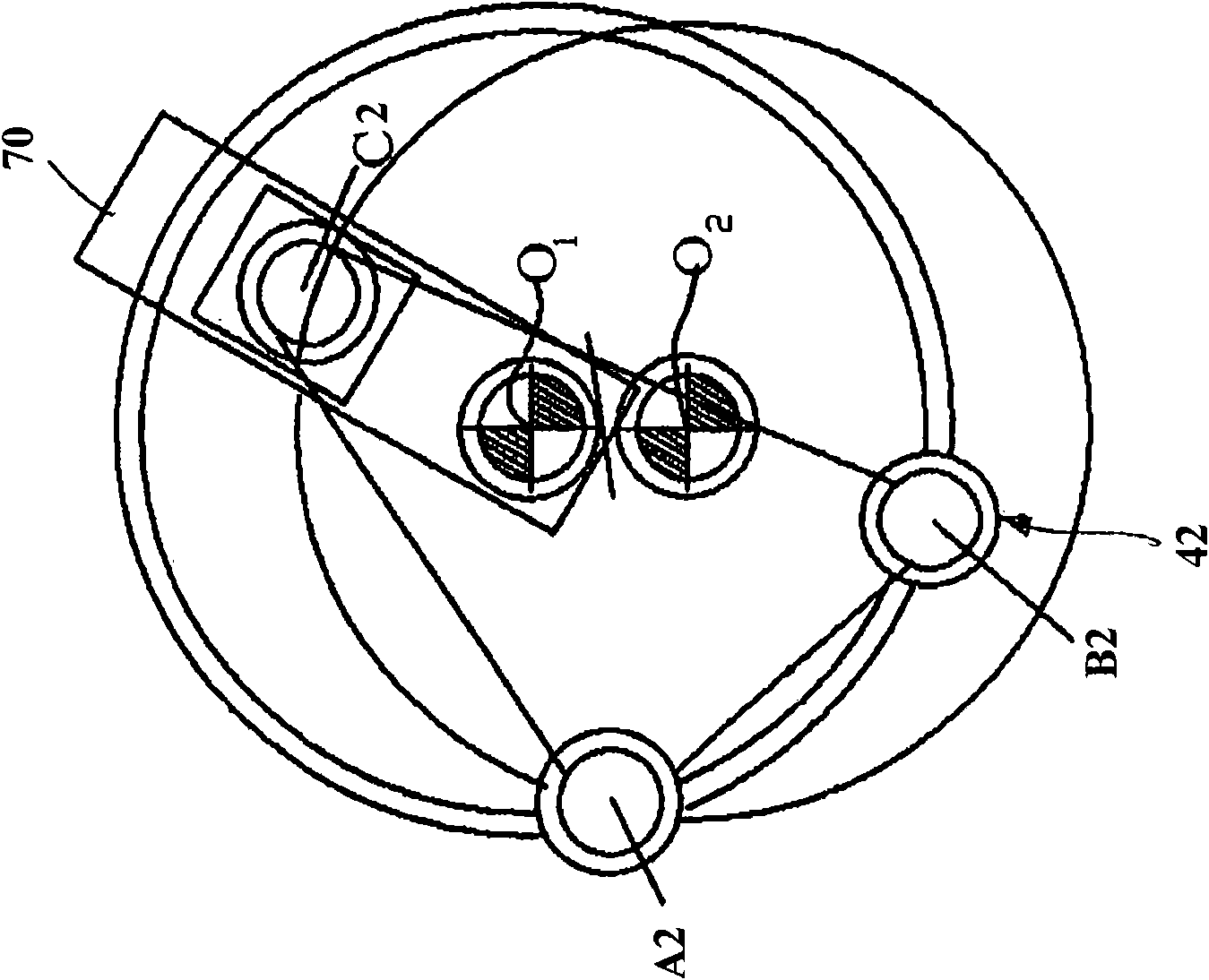

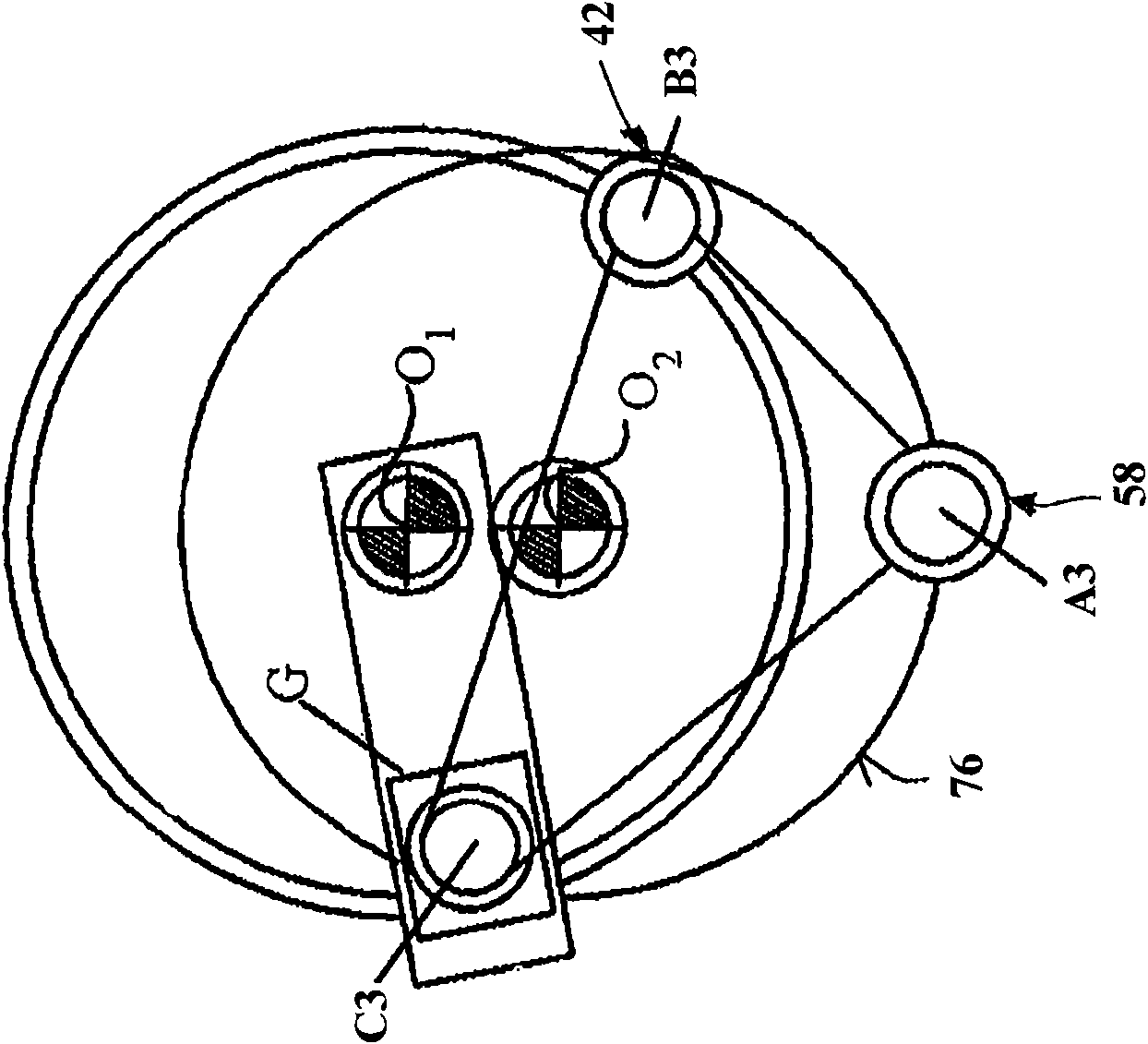

[0028] Figure 2a and 2b The view in FIG. 2 shows a rotary piston machine according to a first embodiment of the invention. exist Figure 2a Note that in the schematic view of , the individual elements there are interlaced as wireframe models, thus also showing lines that are invisible to the observer. It can be seen that the rotary piston machine has a cylinder liner 10 which is rotatably accommodated in a frame 12 . The cylinder liner 10 consists of a cup-shaped section 14 and a cover plate 16 which, in the installed state, close off within the cylinder liner 10 to form a working chamber 18 . The rotor 20 is housed inside the cylinder liner 10 concentrically with the cylinder liner 10 , and this rotor 20 is rotatably mounted with respect to the cylinder liner 10 . The cylinder liner 10 has two opposite, approximately triangular ribs 22 , which originate from the circular wall of the cylinder liner 10 and extend in the direction of the central longitudinal axis. Said rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com