Method for analysis of metal sample

A metal sample and analysis method technology, applied in the direction of testing metal components, preparation of test samples, testing metals, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] Take the solid solution content sol.C of vanadium (V) in the steel sample V And the solid solution content rate sol.C of niobium (Nb) Nb A specific description will be given for an analysis example.

[0111] The steel certification reference materials shown in Table 1 were cut into appropriate sizes, and the surface was sufficiently ground, and analyzed by the method of the present invention and the comparison method shown below. In addition, the composition values other than iron in Table 1 are certified values, and the composition values of iron are calculated values obtained by subtracting the total value of the composition values of elements other than iron from 100%.

[0112] Table 1

[0113] quality%

[0114] Element

C

Si

Mo

V

Ti

Nb

other

(Fe)

JSS165-4

0.051

(0.01)

0.015

0.30

0.015

0.21

0.374

(99.04)

JSS1007-1

0.0024

0.006

0.030 ...

Embodiment 2

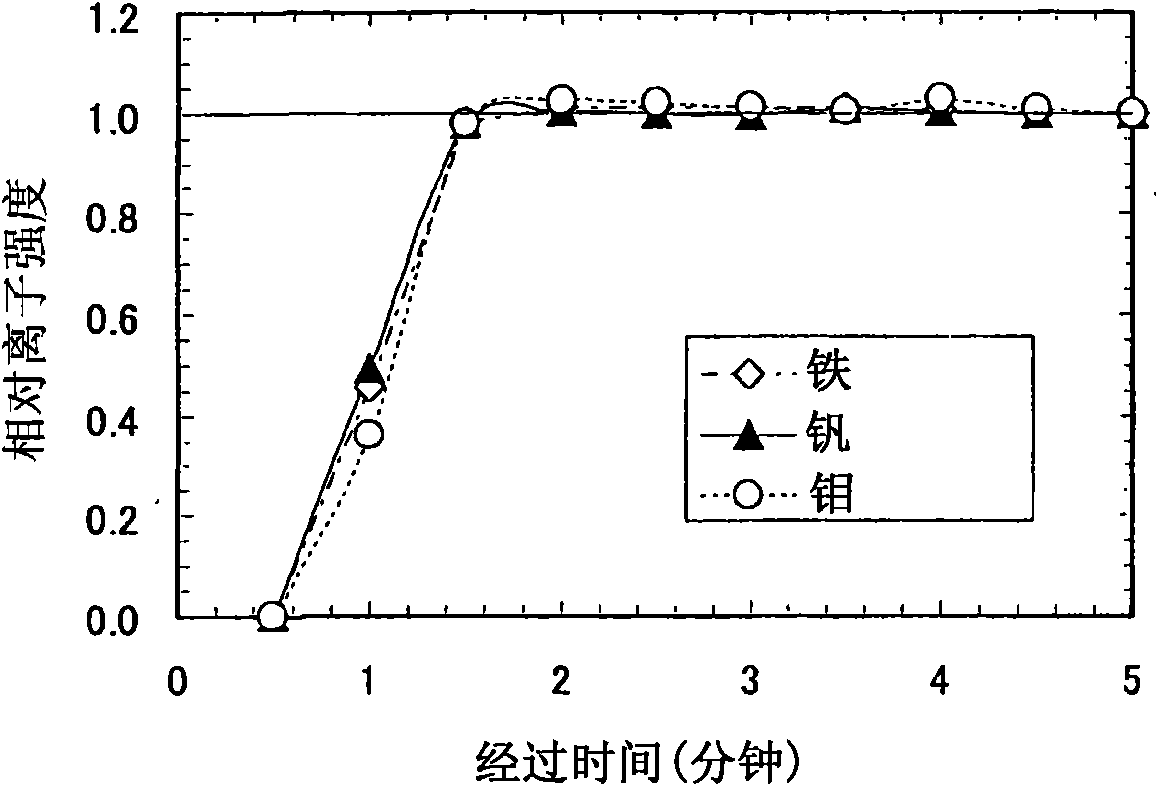

[0132] Hereinafter, for the solid solution content rate sol.C of titanium in the steel sample analyzed as Example 2 Ti example to explain in detail.

[0133] Two steel ingots having the compositions shown in Table 4 were prepared, heated at 1250° C. for 60 minutes, rolled at a working temperature of 1050° C., and then heat-treated under the conditions shown in Table 5. Next, after natural cooling, it was cut to an appropriate size and the surface was sufficiently ground, and then analyzed by the inventive method and the comparative method shown below.

[0134] In addition, the composition values other than iron in Table 4 are values analyzed by ordinary methods such as spark source emission spectroscopy, and the composition value of iron is obtained by subtracting the total value of the composition values of elements other than iron from 100%. Calculated.

[0135] In addition, the analysis of the solid-solution titanium performed on each sample by the inventive method ...

Embodiment 3

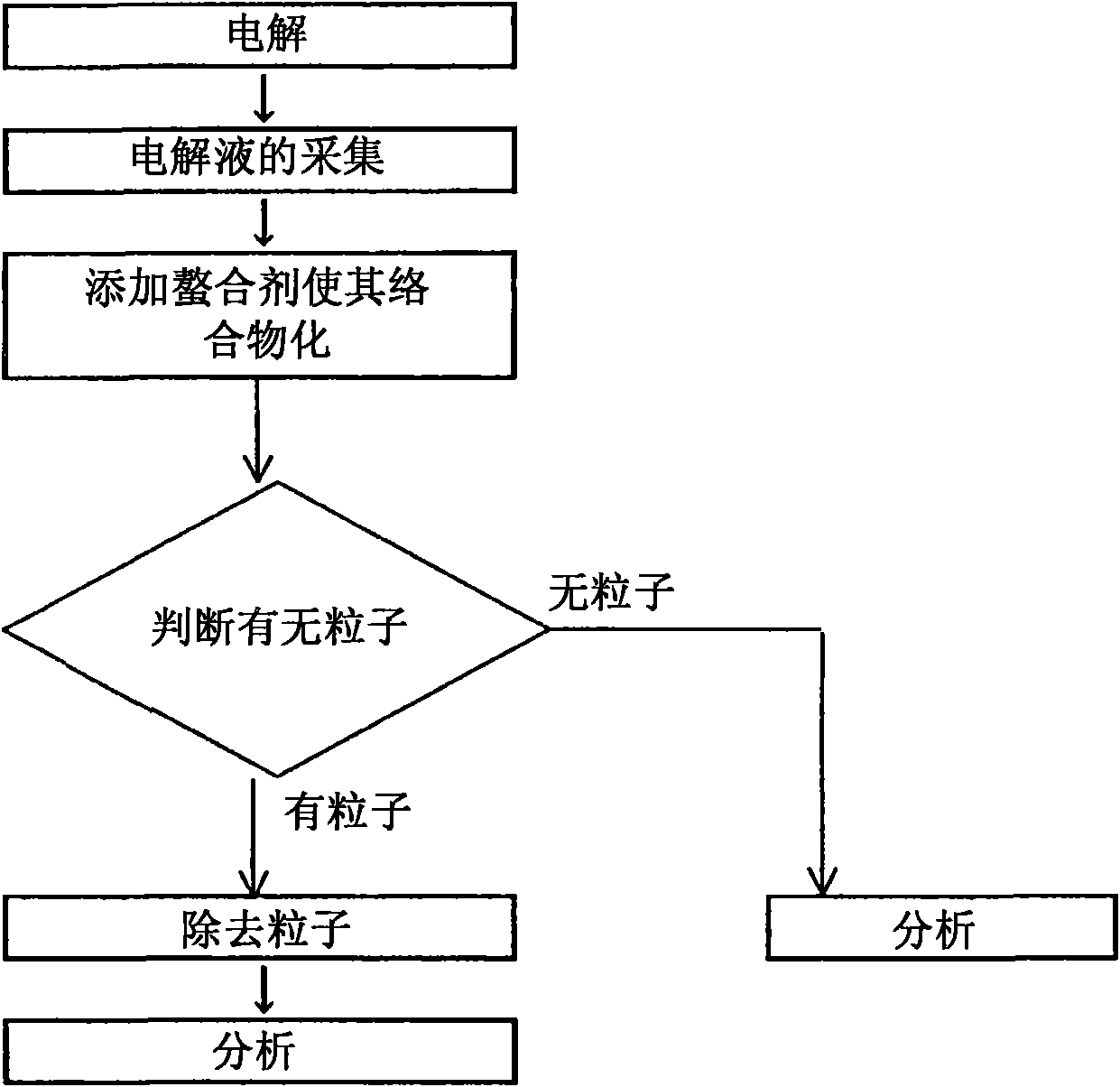

[0160] Hereinafter, an example in which a steel sample is electrolyzed and a part of the electrolytic solution is collected and analyzed as Example 3 will be specifically described.

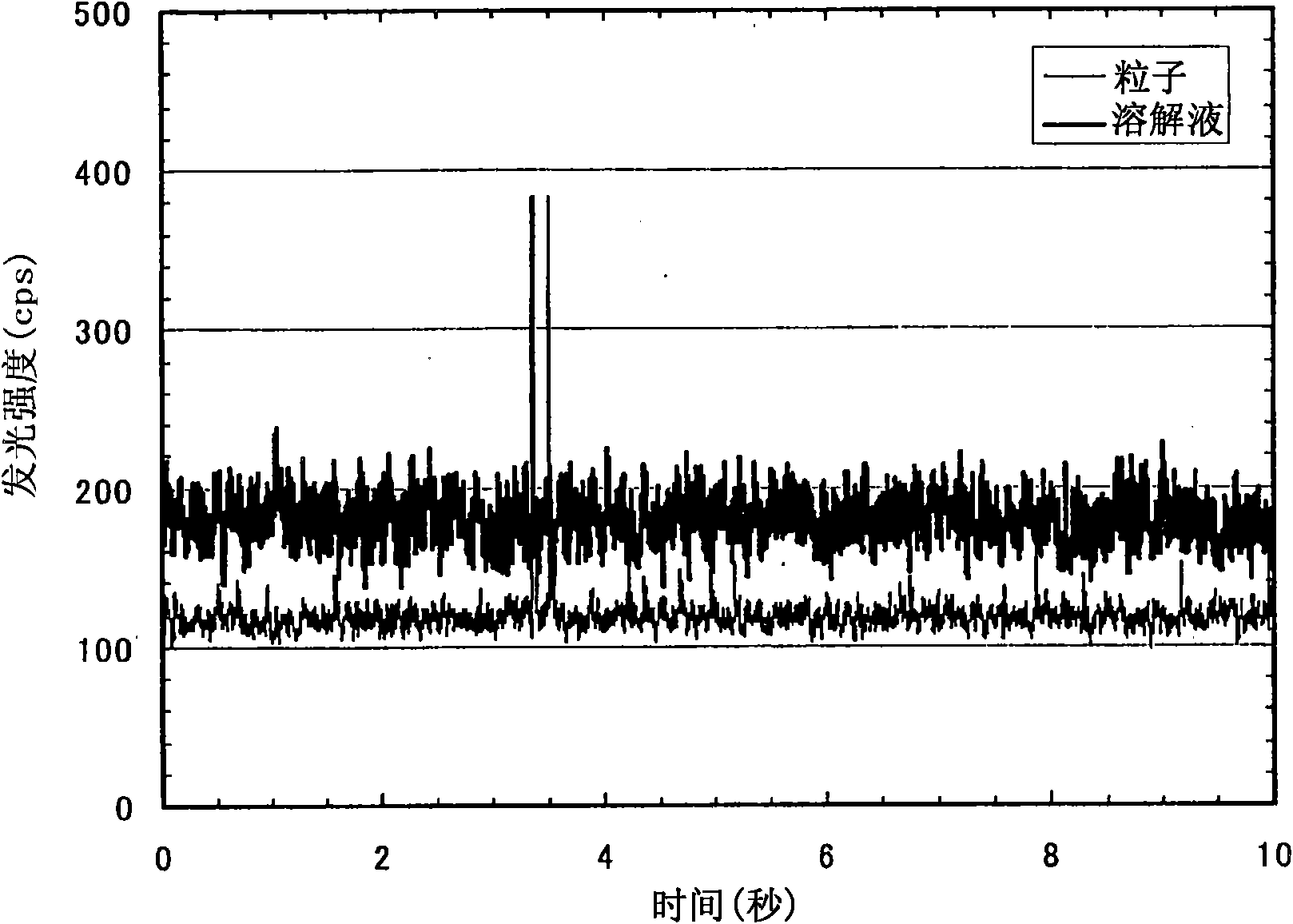

[0161] First, about 0.5 g of the steel certification standard material JSS1008-1 shown in Table 1 was used as an anode in about 300 ml of 10% AA-based electrolyte solution for constant potential electrolysis. About 1ml of electrolyzed electrolyte solution was collected, processed respectively by the method of the present invention and the comparative method as described below, and compared.

[0162] Invention method

[0163] Collect about 1 ml from about 300 ml of electrolyte solution into a test tube, add 0.4 ml of 0.1 mol / L ethylenediaminetetraacetic acid diammonium aqueous solution, and dry it. The residue was heated and dissolved in about 20ml of pure water to obtain an analysis solution, which was introduced into an ICP mass spectrometer to measure the ionic strength of vanadium, iron and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com