Ultralow temperature ice trough

An ultra-low temperature, ice bath technology, used in coolers, lighting and heating equipment, laboratory utensils, etc., can solve the problems of energy waste, poor temperature control accuracy, narrow application range, etc., to achieve flexible temperature adjustment and reduce refrigeration load. , The effect of stable and reliable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

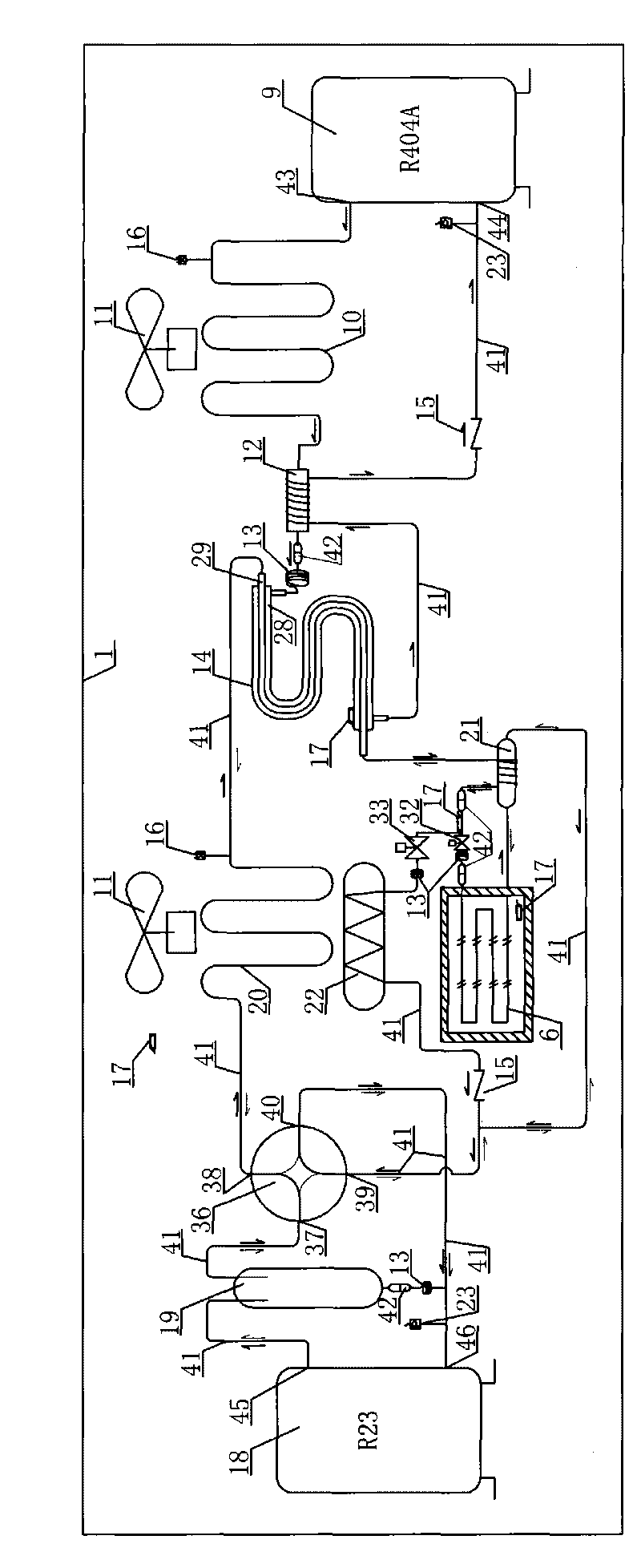

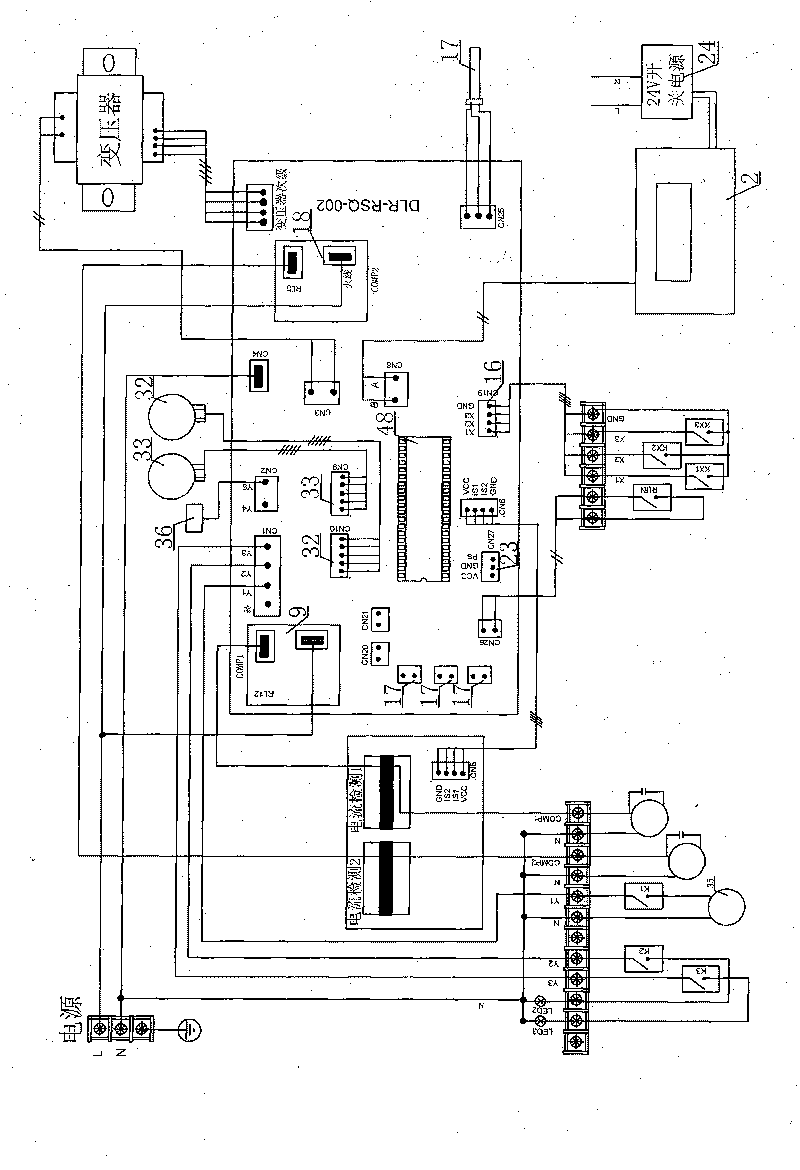

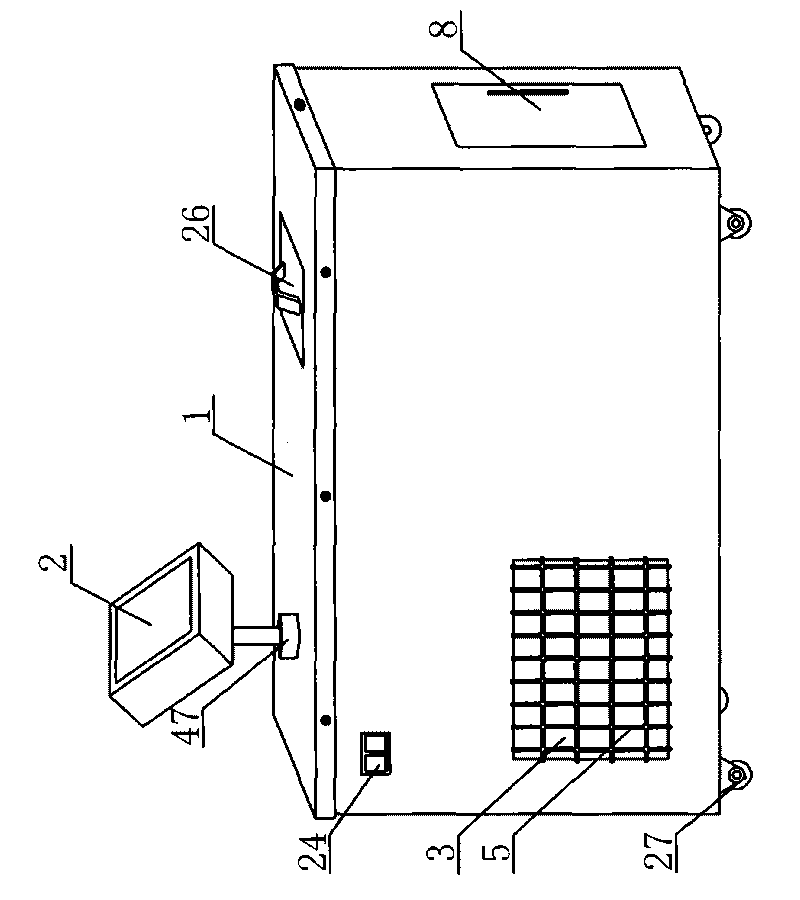

[0044] The structure of the ultra-low temperature ice tank of the present invention includes a casing 1, an ice tank container 30, an operation panel 2, a compressor refrigeration system, an evaporator, a fan motor 11 and electrical parts, an ice tank container 30, a compressor refrigeration system, and an evaporator And the fan motor 11 is arranged inside the box body 1, and the operation panel 2 is arranged on the upper part of the box body 1; A sealing cover 26 is arranged to seal the ice tank container 30; the compressor refrigeration system is connected to the evaporator; the refrigerant discharged from the compressor refrigeration system cools the cooling medium in the ice tank container 30 through the evaporator; the fan motor 11 The condenser in the mechanical refrigeration system cools down. The box body 1 is provided with a fan air inlet 3 near the fan motor 11, and the fan air outlet 4 is opened on the other side of the box body 1 relative to the fan air inlet 3; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com